A dust proof concrete densifier is a specialised liquid treatment. It primarily strengthens concrete floors. Concrete often suffers from dusting and wear because of its porous nature. This treatment offers a solution. A concrete densifier improves the inherent properties of concrete, enhancing its durability and appearance. The floor becomes more dustproof.

Key Takeaways

Concrete densifiers strengthen concrete floors. They stop dust and make floors last longer.

Densifiers work by a chemical reaction. This reaction fills pores and hardens the concrete.

Choosing a lithium-based densifier is best. It gives the strongest and most lasting results.

Why Concrete Floors Dust and Deteriorate

The Inherent Weaknesses of Untreated Concrete

Untreated concrete possesses inherent characteristics that lead to dusting and deterioration. Concrete is a porous material. It contains free lime, also known as calcium hydroxide. This chemical component is a primary cause of dusting on concrete floors. The alkaline, hydrated Portland cement binder in concrete reacts with acidic substances. This reaction causes disintegration. Soluble reaction products form and then remove themselves. Furthermore, calcium leaches from the concrete. This process contributes to deterioration, especially when exposed to environments like seawater with its sulfate content. These factors collectively weaken the concrete surface over time.

Common Issues Faced by Floor Owners

Floor owners frequently encounter several problems with untreated concrete. Ground ash and sand often appear on the surface. This affects the facility’s image and can pose safety risks. Cleaning and maintenance costs become high due to constant dusting. The floor’s life shortens significantly, requiring frequent renovation. This leads to long construction periods, impacting daily operations. Many untreated concrete floors also struggle to meet environmental standards. They often lack a lasting gloss, demanding continuous maintenance to appear presentable. This constant upkeep adds to the overall burden of concrete flooring.

How Concrete Densifiers Work

The Science Behind Densification

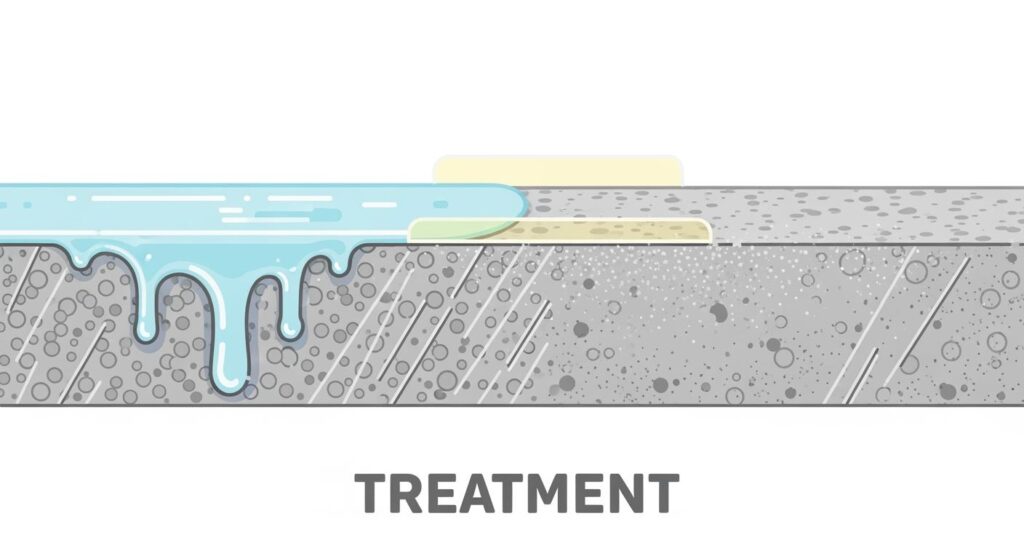

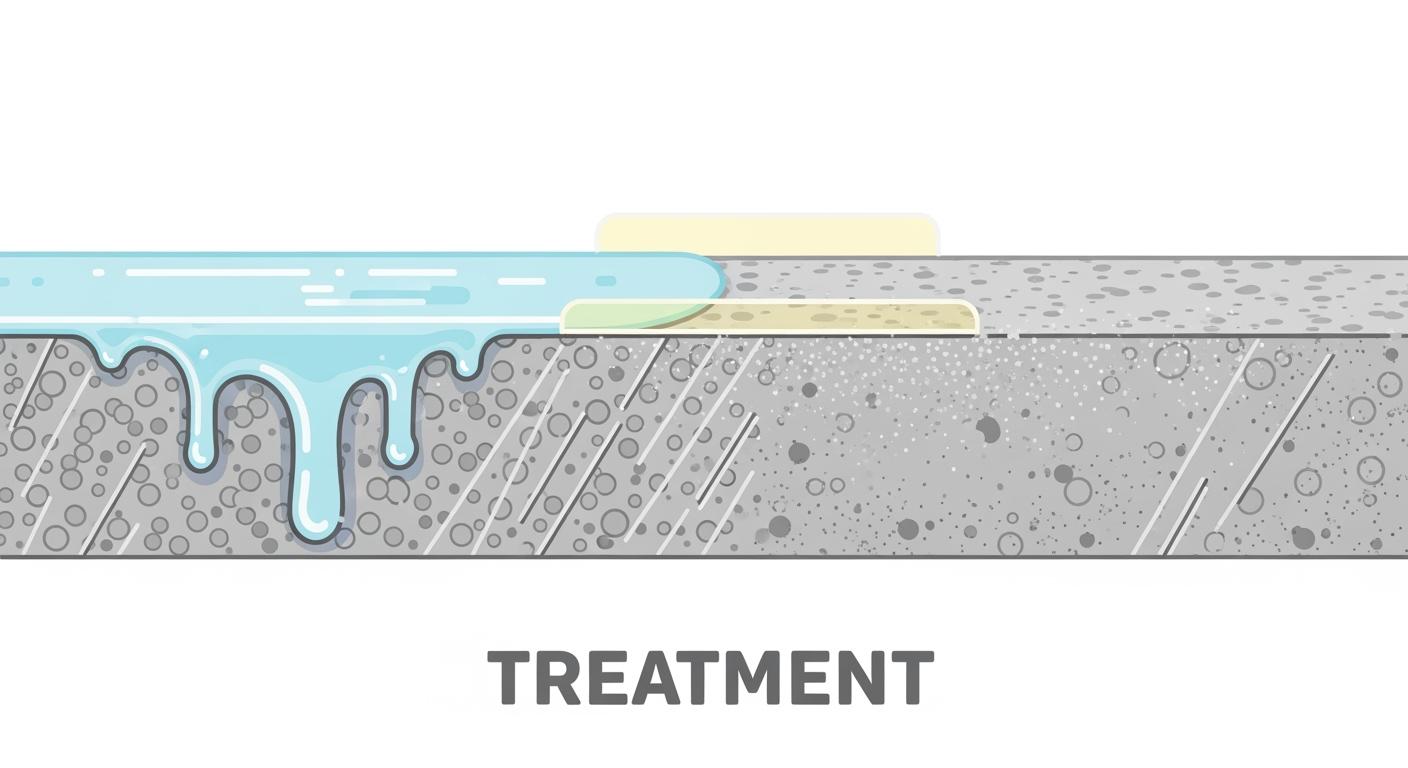

A concrete densifier is a liquid chemical that transforms the inherent properties of concrete. It works through a specific chemical reaction. The silicates within the densifier react with the calcium hydroxide, also known as free lime, present in the cement. This reaction forms calcium silicate hydrate (CSH). CSH is a crystalline structure. It fills the pores and microcracks within the concrete. This process strengthens and hardens the concrete. The densifier also reacts with calcium carbonate, another byproduct of the curing process. This chemical interaction is central to what is densification. It seals pores, fuses inert compounds and sand particles into a crystalline bond. This strengthens the concrete mass, protecting it from deterioration. Sodium silicate densifiers, for example, penetrate concrete pores and undergo this reaction. Similarly, colloidal densifiers, which contain nano-sized particles, also react with free lime to produce C-S-H. This C-S-H is the primary compound responsible for concrete’s strength. Its formation fills pores and capillaries, increasing density and reducing porosity.

Deep Penetration and Permanent Hardening

Concrete densifiers achieve deep penetration into the concrete slab. This ensures a permanent hardening of the surface. BANDě’s high-active lithium-based formula, for instance, penetrates 3-8mm deep. It reacts with free calcium and magnesium ions within the concrete. This deep penetration allows the densifier to create a robust, internal strengthening effect. The chemical reaction is not merely a surface treatment. It permanently alters the concrete’s internal structure. This process of densification makes the concrete significantly more resistant to wear and tear. The result is a floor with increased surface density and durability. This permanent hardening means the concrete will not dust or deteriorate as easily. A dust proof concrete densifier provides lasting protection. This deep densification ensures the benefits are long-term, unlike temporary coatings.

Benefits of Concrete Densifiers

Concrete densifiers offer numerous advantages, directly addressing the common problems associated with untreated concrete floors. These solutions transform a vulnerable surface into a robust and aesthetically pleasing one.

Eliminating Dusting

One of the primary benefits of applying a concrete densifier is the complete elimination of dusting. Untreated concrete constantly releases fine particles, creating dust that settles on surfaces and contaminates goods. A concrete densifier works by sealing the concrete’s capillaries. This process prevents the release of sand and dust particles. BANDě products, for example, provide “dust-proof and anti-fouling, worry-free cleaning.” This ensures a clean environment and a truly dustproof surface. The chemical reaction within the concrete creates a solid, non-dusting layer, making the floor a permanent dust proofer. This effective dustproofing significantly improves air quality and reduces cleaning efforts.

Increased Hardness and Durability

Concrete densifiers dramatically enhance the surface’s resistance to abrasion and impact. The densification process creates an increased surface hardness. This makes the concrete much more resilient to daily wear and tear. For instance, BANDě densifiers boast “compressive strength increased by more than 40%, wear resistance increased by 300%.” This substantial improvement means the floor can withstand heavy traffic and impacts without showing significant damage. The treated concrete becomes an abrasion and stain resistant surface, capable of enduring harsh conditions. This increased durability translates into a longer-lasting floor that requires less frequent repair.

Enhanced Shine and Aesthetics

Densifiers also significantly improve the floor’s appearance, especially when polished. The treatment creates a denser, smoother surface. This surface reflects light more effectively. BANDě densifiers offer a “lasting shine, brighter with use” and a “natural crystal gloss after polishing.” This aesthetic enhancement transforms dull, grey concrete into an attractive, high-gloss finish. The improved look contributes to a more professional and clean environment, elevating the overall impression of the space.

Easier Cleaning and Maintenance

A densified concrete floor is much easier to clean and maintain. The reduced porosity of the concrete means dirt, grime, and liquids cannot penetrate the surface as easily. This creates a dustproof surface that resists stains. BANDě densifiers specifically resist oil and water stains. Research from the American Concrete Institute indicates that concrete densified with lithium silicate and polished to 800 grit or higher shows a 92–97% reduction in water absorption compared to untreated concrete. This reduction in porosity directly impacts the cleaning frequency. Post-densifying maintenance is minimal, requiring only regular cleaning with neutral pH cleaners.

Finish Type | Porosity Level | Recommended Cleaning Frequency |

|---|---|---|

Matte (Honed) | Medium | Weekly damp mop |

Semi-Gloss | Low | Bi-weekly |

High-Gloss (Mirror) | Very low | Daily dust mop + weekly wet |

This table illustrates how densification reduces cleaning needs.

Extended Floor Lifespan

The application of concrete densifiers significantly prolongs the service life of concrete floors. The hardening and sealing properties protect the concrete from deterioration, abrasion, and chemical attack. This extended protection means the flooring lasts much longer than untreated concrete. BANDě densifiers offer “super durability, life up to 15 years or more.” This longevity reduces the need for costly repairs or complete floor replacement. The initial investment in densification pays off through years of trouble-free performance.

Eco-Friendly Solutions

Modern concrete densifiers also offer significant environmental benefits. Many products are “green and environmentally friendly, safe and harmless.” They often feature a “water-based formula, non-toxic and odourless, very low VOC content.” For example, MACt Lithium Densifier has 0% VOC content, while AquaSeal-Harden has 42 g/L. These low VOC (Volatile Organic Compound) levels ensure better indoor air quality and comply with environmental regulations. Using these concrete densifiers contributes to sustainable building practices.

Applying a Concrete Densifier

When to Apply

For new concrete floors, proper curing is essential before applying a concrete densifier. Experts recommend a minimum of two hours cure time for freshly poured, or ‘green’, concrete. However, for optimal results, allow the concrete to cure for at least seven days before application. This ensures the concrete is dry inside. This preparation allows the densifier to react effectively with the concrete’s internal structure.

The Application Process

Applying a densifier is a straightforward process. Workers can use direct spraying or rolling methods. This makes for convenient construction and a short cycle. After application, the floor dries quickly. It can typically be put into light use within 24 hours. For optimal densification and resistance to oil and water, a longer curing time of seven days or more is recommended.

New vs. Existing Floors

Densifiers offer wide applicability and strong compatibility for various floor types. These include new and old concrete, emery floors, and terrazzo. For existing floors, thorough surface preparation is crucial. The surface must be clean, dry, and free from contaminants such as oil, grease, or existing sealers. This may involve sweeping, vacuuming, and using a degreaser for stains. A pressure washer can tackle stubborn marks. A water drop test can check porosity; if water beads, further preparation may be necessary.

Choosing the Right Concrete Densifier

Selecting the appropriate concrete densifier is crucial for achieving the desired floor performance and longevity. Various types exist, each with distinct chemical properties and performance characteristics. Understanding these differences helps in making an informed decision for any project.

Types of Densifiers: Sodium, Potassium, and Lithium

Concrete densifiers primarily come in three main types: sodium, potassium, and lithium silicates. These differ significantly in their molecular size and how they react with the concrete.

Feature | Sodium Silicate | Potassium Silicate | Lithium Silicate |

|---|---|---|---|

Molecular Size | Largest molecules | Smaller than sodium, larger than lithium | Smallest molecules |

Penetration | Difficult to evenly penetrate tighter finishes | Deeper penetration than sodium | Evenly penetrates tight finishes, deeper penetration |

Reaction Consist. | Reacts inconsistently, leaves weak spots | Reacts inconsistently, leaves weak spots | Evenly reacts, fills all empty pores, no inconsistencies |

Resulting Props. | Single structure, prone to deterioration, dusting | Prone to deterioration, dusting | Forms stable tri-calcium silica structures, insoluble, greater density, resistance to abrasion, dusting, attack, increased hardness, long-term durability, dust-proofed |

Lithium-based densifiers offer superior performance. Their smaller molecules allow for much greater and deeper penetration into the concrete. This leads to a more complete and even reaction with the calcium hydroxide present in the concrete. This process of densification forms stable tri-calcium silicate structures. These structures provide increased hardness, greater density, and enhanced resistance to abrasion and dusting. Lithium silicates also reduce the risk of surface discolouration or efflorescence, unlike sodium or potassium variants which may leave residue. They are less soluble and less alkaline, preventing issues like map cracking and Alkali Silica Reactivity (ASR).

Factors to Consider for Your Project

Several factors influence the choice of a concrete densifier. The condition of the existing floor, whether new or old, plays a significant role. The desired aesthetic finish, such as a high-gloss polish, also guides the selection. Project budget and environmental considerations, like VOC content, are important. Application rates also vary between products. For example, NeverStrip Densi-Prime covers 1,250 to 2,500 sq ft per gallon, while AquaSeal-Harden covers 250-400 sq ft per gallon. C2 Hard LITHIUM Densifier covers 200–400 m² per 20 L pail. Always consult product specifications to ensure compatibility and optimal results for your specific concrete densifier application.

A dust proof concrete densifier transforms concrete floors. It offers lasting protection. This solution provides a durable, attractive, and easy-to-maintain surface. It is cost-effective long-term. Choosing the correct concrete densifier is vital. It ensures optimal floor performance and extended lifespan. A dust proof concrete densifier delivers significant value.

FAQ

What is the main difference between densifiers and sealers?

Densifiers chemically react with concrete, hardening it internally. Sealers form a protective layer on the surface. Densifiers offer permanent internal strengthening.

How long does a densified concrete floor last?

A properly densified concrete floor can last 15 years or more. The treatment permanently strengthens the concrete, extending its lifespan significantly.

Can you apply a densifier to any concrete floor?

Yes, densifiers work on new and old concrete, emery floors, and terrazzo. Proper surface preparation is crucial for existing floors.

Note: Always check product specifications for specific compatibility.

See Also

Understanding Concrete Densifiers: Their Functionality and Practical Application Explained

BANDě Concrete Densifier: Unravelling Its Mechanism and Operational Principles

BANDě Concrete Densifier: A Detailed Exploration of Its Working Process

Concrete Densifiers Versus Hardeners: Discerning Their Key Distinctions Clearly

Liquid Concrete Solutions: Hardener, Sealer, and Densifier Explained Thoroughly