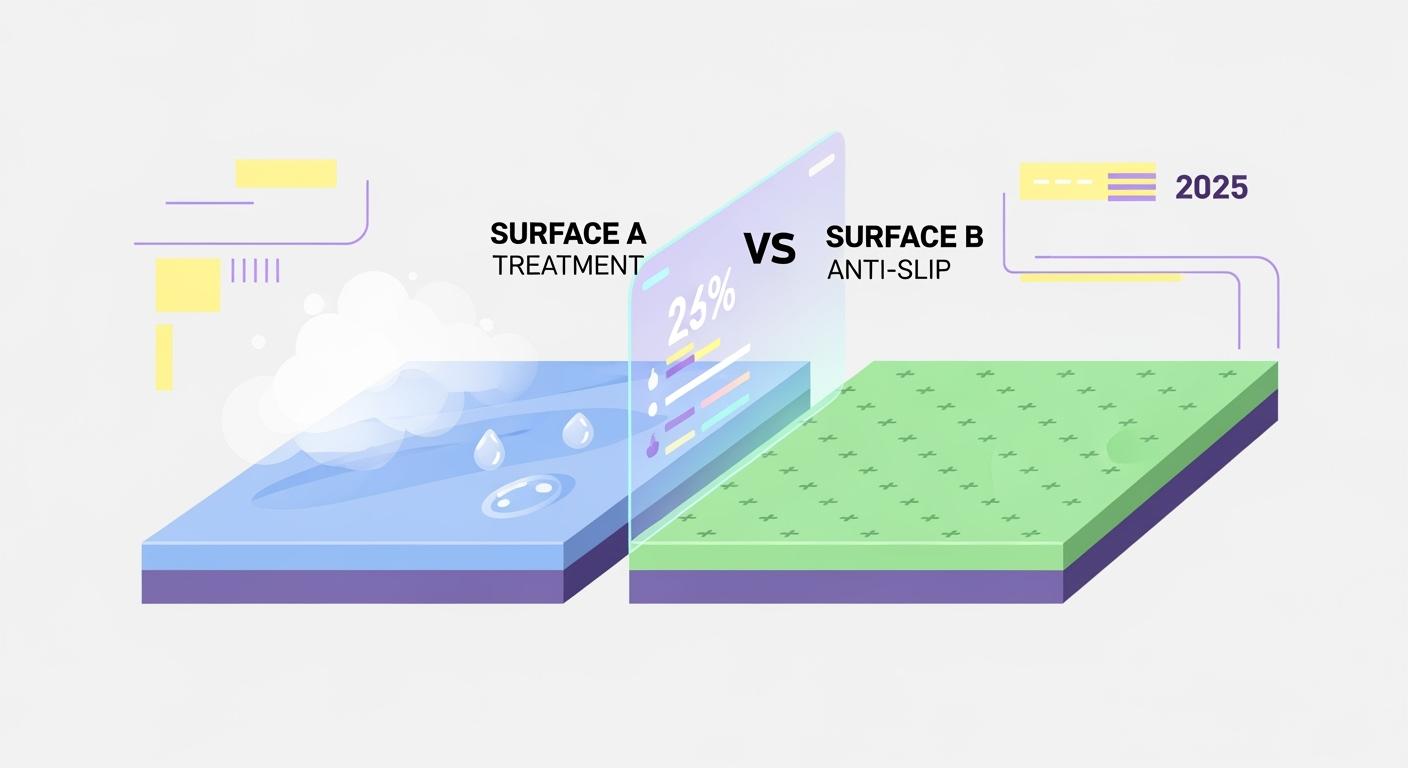

Slips and falls lead to serious injuries and expensive accidents, making up 20% of workplace injuries and costing millions annually. Effective slip resistance is crucial to prevent hazards on slippery floors. We compare chemical non-slip treatment and anti-slip floor coating options, including non-slip coatings and anti-slip floor treatment. Our 2025 guide helps you choose the best anti-slip solution for your overall non-slip safety and anti-slip protection, ensuring a reliable non slip treatment.

Key Takeaways

Chemical non-slip treatments change your floor’s surface to make it less slippery. They work best on hard floors like tile and concrete.

Anti-slip coatings add a new layer to your floor to create grip. They work on many surfaces like concrete and metal.

Choose between treatments and coatings based on your floor type, how much people walk on it, and your budget. Think about what works best for your specific needs.

Chemical Non-Slip Treatments Explained

How Chemical Non-Slip Treatments Work

Chemical non-slip treatments are quite clever. They do not add a layer to your floor. Instead, this non slip treatment chemically alters the surface itself. Think of it as microscopic etching. The treatment creates tiny pores or channels on your floor. This process gives the surface a better texture and grip. It makes the floor less slippery when wet. This is a true anti slip treatment, changing the floor’s structure.

Surfaces Best Suited for Chemical Treatments

You will find chemical anti slip floor treatment works best on hard mineral surfaces. These include ceramic, porcelain, and quarry tiles. Concrete also responds well to this method. Some natural stones can benefit, but you must use caution. Always test a small, hidden area first.

Advantages of Chemical Non-Slip Solutions

One big advantage is the invisible change. The treatment maintains your floor’s original look. It creates durable slip-resistant surfaces. This is especially good for areas that get wet often. You get significantly improved slip resistance. This anti-slip solution offers lasting resistance without changing aesthetics. It is an effective anti slip floor treatment.

Potential Downsides of Chemical Anti-Slip Treatment

While effective, this chemical anti-slip treatment has some drawbacks. It can sometimes alter the appearance of highly polished surfaces. For example, on polished stone floors, you might see pitting of the stone surface. It can open the pores of the stone. If you later polish the material, these pits remain. This degrades the aesthetic quality. It also weakens the stone’s inherent vulnerability. This non-slip treatment is permanent. It is not suitable for all materials. You might also notice a slight reduction in shine.

Anti-Slip Floor Coatings Overview

What are Anti-Slip Floor Coatings?

You apply anti-slip floor coatings as a physical layer. They do not damage your floor’s chemical structure. Instead, they create a new, textured surface. These coatings often use polymers like epoxy or urethane. Epoxy is strong for warehouses; urethane offers flexibility and chemical resistance for food processing. Manufacturers add aggregates like polypropylene, Polymer ColorFlakes, or Quartz ColorGranules. These additives create texture and improve slip resistance, making them an effective slip resistant coating.

Application of Non-Slip Floor Coatings

Applying a non-slip floor coating requires careful preparation. You must thoroughly clean your concrete surface, repair cracks, and test for moisture. Skipping these steps causes peeling. First, vacuum or sweep dirt. Use a pressure washer for grime. Apply a specific cleaning solution for oil. Rinse and let the floor dry completely. Repair cracks with filler. A moisture test is crucial; condensation means excess moisture. Finally, use a primer for better adhesion of your non-slip coatings.

Ideal Surfaces for Anti-Slip Coatings

Anti-slip coatings work well on many surfaces, especially concrete or metal. Industrial settings benefit greatly: warehouses, distribution centers, commercial kitchens, food processing plants, and healthcare facilities. These coatings provide a protective layer, offering enhanced cleanability and chemical resilience. This makes them ideal where toxic spills are a risk. Epoxy surfaces with anti-slip additives are perfect for areas with moisture or oil, significantly reducing falls on slippery floors.

Benefits of Anti-Slip Floor Coatings

You gain many benefits from a non-slip floor coating. They create a durable protective layer, withstanding heavy machinery and chemical exposure. They also offer excellent grip, helping you meet safety guidelines. High-quality industrial epoxy coatings can last 10 to 20 years, depending on correct installation and maintenance. Regular cleaning and inspections extend their life. These non-slip coatings also offer enhanced cleanability and fire-retardant qualities once cured. They improve facility safety and help create anti-slip surfaces.

Disadvantages of Anti-Slip Floor Coatings

While beneficial, anti-slip floor coatings do have some drawbacks. The initial cost can be higher than chemical treatments. You also need to reapply them over time. Wear from heavy traffic reduces effectiveness. If you do not prepare the surface correctly, the coating might peel. This means you need professional application. Some non-slip coatings might also alter your flooring’s look more noticeably.

Key Differences: Treatments vs. Coatings

When you choose a solution for slippery floors, understanding the core differences between chemical non-slip treatments and anti-slip coatings is crucial. You are not just picking a product; you are selecting a method that interacts with your floor in distinct ways. Let’s break down these key distinctions.

Mechanism: Etching vs. Layer Application

The most fundamental difference lies in how they work. A chemical non-slip treatment chemically etches your floor’s surface. It creates microscopic pores or channels, making the surface rougher at a tiny level. This process changes the floor itself. Think of it as texturing the existing material. On the other hand, a non-slip floor coating applies a new physical layer on top of your existing floor. This layer contains aggregates that provide the grip. It does not alter the original surface underneath. This means an anti-slip treatment changes the floor’s structure, while a non-slip coating adds a new one.

Surface Impact and Integrity

Chemical treatments directly alter your floor’s surface. This can sometimes affect the original integrity, especially on highly polished or softer materials. For instance, a chemical anti slip treatment might open up pores on natural stone, making it more susceptible to staining if not properly sealed afterward. However, many chemically treated floors, especially those made from specific study materials, show excellent abrasion resistance. They do not easily wear down when objects drag across them. Porcelain and some ceramic tiles, inherently resistant to abrasion and tread wear, handle heavy foot traffic well after chemical treatment. In contrast, non-slip coatings add a protective layer. They do not change the original surface’s chemical structure. This layer can shield your floor from wear, chemicals, and impacts.

Durability and Wear Resistance

How long your chosen solution lasts depends heavily on its durability and resistance to wear. Chemical non-slip treatments offer good resistance to wear and abrasion because they are part of the floor itself. For example, some chemical treatments achieve a Shore Hardness D of 84 after just three days, indicating significant surface hardening. This means the anti slip floor treatment becomes an integral part of the floor’s wear surface. However, heavy pedestrian traffic can still gradually smooth out the microscopic etching over time, reducing its effectiveness.

Non-slip coatings, while providing excellent slip resistance, vary greatly in their durability. High-quality industrial coatings like Stonseal GS6 offer superior chemical and abrasion resistance, acting as a tough, UV-stable top coat. Stonseal PA7, a pigmented urethane coating, enhances cleanability and abrasion resistance. Even clear flat coatings like Stonseal CF7 improve resistance to stains, abrasion, and UV, making them suitable for demanding environments. However, water-based anti-slip coatings are generally not durable. They wear down quickly under foot traffic, requiring frequent reapplication. You will find that the effectiveness of any non-slip solution can change significantly with constant wear.

Aesthetic Changes and Appearance

Chemical non-slip treatments aim to be invisible. They typically do not change your floor’s appearance. You get improved grip without altering the look. However, on very high-gloss surfaces, you might notice a slight dulling or a subtle change in reflectivity. Non-slip coatings, on the other hand, create a new surface. They can be clear, colored, or textured. This means they will change your floor’s appearance. You can choose coatings that match your aesthetic needs, but they will always add a visible layer.

Maintenance and Longevity

Maintaining chemically treated floors is usually straightforward. You clean them as you normally would. The non-slip properties are part of the floor, so they do not peel or chip. Their longevity depends on the original floor material and traffic levels. Coatings require different maintenance. You need to clean them carefully to avoid damaging the textured surface. Their longevity varies widely. High-quality industrial non-slip coatings can last many years, but they may eventually need reapplication, especially in high-traffic areas.

Cost-Effectiveness Over Time

When you consider cost, look beyond the initial price tag. Chemical non-slip treatments often have a lower upfront cost. They are a one-time application that lasts for a significant period, making them cost-effective in the long run if the surface holds up. For coatings, the initial investment can be higher. However, durable options like polyurethane and epoxy sealers offer superior durability and reduce reapplication frequency compared to cheaper alternatives like acrylic sealers. A study showed premium epoxy sealers improved durability by 40% on high-traffic surfaces, lowering lifetime maintenance costs.

Consider an anti-stain coating for shower glass; it is an extra initial treatment but saves you from replacing an entire enclosure later. This extends the life of your existing glass. Similarly, while a ceramic coating for a car might cost $1,000–$2,500 initially, it lasts 2–5 years. Car wax, at $100–$200, needs reapplication every 2–3 months. This shows how initial investment can lead to long-term savings by reducing maintenance and replacement costs. You save on professional wash fees and preserve resale value.

Choosing Your Non-Slip Solution

You have learned about chemical treatments and anti-slip coatings. Now, you need to decide which one works best for you. This choice depends on many factors unique to your situation. You want to make an informed decision to ensure lasting safety and effectiveness.

Assessing Your Environment and Needs

Before you pick a solution, take a good look at your space. What kind of environment is it? Is it a busy commercial kitchen, a quiet office hallway, or a residential bathroom? Each setting presents different challenges and hazards. Think about what makes your floors slippery. Is it water, oil, grease, or something else? Understanding these details helps you choose the right non-slip treatment. For example, a slip-resistant bathroom needs a solution that handles constant moisture without compromising aesthetics.

Surface Type and Condition

The type of floor you have plays a huge role. Chemical treatments work best on hard mineral surfaces like ceramic, porcelain, and concrete. They etch the surface to create microscopic grip. If you have a highly polished natural stone, a chemical non slip treatment might dull its shine. On the other hand, anti-slip coatings are more versatile. You can apply them to almost any surface, including concrete, metal, and even wood, creating a new non-slip layer. Consider your floor’s current condition too. Is it old and worn, or new and pristine? A coating can also help protect an older flooring surface.

Traffic Levels and Usage Demands

How many people walk on your floor every day? What kind of activities happen there? High-traffic areas demand more durable solutions. For example, a shopping mall floor needs extreme durability. A PEI rating of 5 indicates suitability for high-traffic floors in busy public buildings like shopping malls and airports. When you consider slip resistance, look at the Dynamic Coefficient of Friction (DCOF). A DCOF of 0.43 or greater means high slip resistance. Values between 0.30 and 0.42 are acceptable but carry an increased chance of slipping. Anything below 0.30 means low slip resistance and a higher chance of falls.

For areas with heavy foot traffic, like commercial kitchens or locker rooms, Quartz Floor Coating is an ideal choice. If you manage industrial facilities or warehouses, Epoxy Floor Coating offers excellent durability against heavy traffic and equipment. Even retail spaces and showrooms benefit from Metallic Floor Coating, which also withstands high levels of traffic. These coatings protect your underlying surface from wear and tear, ensuring long-term effectiveness. You want a solution that can stand up to daily demands without quickly losing its anti-slip properties.

Budget and Long-Term Value

Your budget is always a factor, but think about long-term value, not just initial cost. A cheaper solution might need frequent reapplication, costing you more over time. For instance, you might consider a DIY non-slip floor coating. However, professional application often provides superior results.

Feature | DIY Application | Professional Application |

|---|---|---|

Material Cost (Epoxy Kits) | $1 to $3 per square foot (materials only) | Included in overall professional cost |

Material Quality | Consumer-grade, often lacks professional performance/longevity | Superior resin systems |

Additional DIY Costs | Surface preparation equipment rental, specialized tools | N/A (included in service) |

Application Quality | Potential for failed installations | Superior results due to proper preparation, quality materials, experienced techniques |

Long-term Costs | Often higher due to potential for failed installations requiring removal and reinstallation | Justified by long-term performance, avoids reinstallation costs |

Protection/Guarantees | None | Liability insurance, warranties for defects/failures |

While DIY epoxy kits might seem cheaper upfront, professional application uses superior materials and techniques. This leads to better long-term performance and avoids costly reinstallation if a DIY job fails. Investing in a quality solution from the start can save you money and headaches down the road, especially for high-risk areas where preventing slippery floors is critical. You want the best slip resistant treatment for tile floors or any other surface to avoid future hazards. If you have a slippery epoxy floor, a professional anti-slip coating can transform it.

BANDě Solutions for Enhanced Safety

When you need reliable non-slip solutions, BANDě offers a range of products designed for various needs. They provide advanced anti-slip coatings that deliver superior durability and performance. Whether you are dealing with a commercial kitchen, an industrial warehouse, or a public space, BANDě has options that meet stringent safety standards. Their expertise helps you navigate the complexities of choosing the right product, ensuring you get an effective solution tailored to your specific environment. You can trust their products to enhance the safety of your flooring.

You’ve seen chemical treatments etch, while anti-slip coatings add a layer. Neither is superior; your needs guide the choice. For 2025, advanced anti-slip floor coating options like polysiloxane (e.g., SparkleTuff) offer incredible durability and excellent non-slip properties, unlike temporary non-slip coatings. Assess your situation to choose the best anti-slip strategy.

FAQ

Can I apply anti-slip coatings myself?

You can apply some DIY kits. However, professional application ensures better results and durability. Proper surface preparation is key for success.

Do chemical treatments change my floor’s appearance?

Chemical treatments usually do not change your floor’s look. On very shiny surfaces, you might notice a slight dulling. They work invisibly.

How long do anti-slip solutions typically last?

Longevity varies. Chemical treatments last years, depending on traffic. High-quality coatings can last 10-20 years with proper care. Water-based coatings wear faster.

See Also

Comparing Industrial Floor Hardeners: Your 2025 Guide to Durable Surfaces

Achieving Safer Floors: An Easy Guide to Anti-Slip Tile Treatment

Top Concrete Protective Sealers of 2025: Upgrade Your Surfaces Today

Expert Waterproof Coating Application: Mastering Protection for Any Surface

Ultimate Guide to Concrete Sealer: Protecting Your Industrial Floors Effectively