I love how popular polished concrete floors have become! This concrete flooring option, growing over 5% annually, offers incredible durability, low maintenance (saving up to 90% on upkeep compared to other concrete flooring), and a modern aesthetic. But how do you polish concrete floors for a professional polished concrete look? BANDě Products make concrete polishing simple, giving you superior, long-lasting polished results every time.

Key Takeaways

Good preparation is important before polishing concrete floors. This includes cleaning, fixing cracks, and grinding the surface.

BANDě products help you polish concrete floors step-by-step. You use different tools and pads to make the floor smooth and shiny.

After polishing, you must protect the floor with a sealant. This keeps the polished concrete looking good and makes it last longer.

Essential Preparation for Polishing Concrete Floors

Before I even think about the beautiful sheen of polished concrete, I know that proper preparation is absolutely key. It’s like building a house; a strong foundation makes all the difference for a lasting finish.

Surface Assessment and Initial Cleanup

My first step is always to thoroughly assess the concrete flooring. I look for common imperfections like “ghost shadows” from old VCT, spalling, trenches, inconsistencies, and cracks. I also check for obstructions like bolts sticking up and pinholes. To understand the concrete’s readiness for concrete polishing, I might use a rebound hammer for overall hardness or a Mohs scratch test for surface hardness. I also check porosity by dripping water; if it penetrates within a minute, it’s porous.

Removing Existing Flooring and Sealing Cracks

Next, I tackle any existing flooring. For epoxy coatings or mastic, I find grinding or shaving works best. If it’s old carpet glue, I might use buffing with a swing machine or even chemical treatments. Once the old layers are gone, I focus on repairs. For minor flaws, I use a skim-coat material. Deeper cracks need anchoring cement or a self-leveling overlay. For active cracks, I chase them with a V-grooved diamond blade, clean them, and then fill them with a semi-rigid polyurea. BANDě’s Hi-Tech Spall TX3 Crack Repair is excellent for quick fixes on small cracks and spalls, making the surface smooth for the upcoming concrete grinding.

Deep Cleaning and Degreasing with BANDě Solutions

After repairs, I move to deep cleaning. Concrete’s porous nature means it absorbs a lot, so I often find oil, grease, dust, dirt, grime, and various stains. This is where BANDě Solutions shine! I use their Bone Dry Concrete Degreaser, which has a pH of 13-14 and is a concentrated, water-based blend. I apply it with a pump sprayer, let it penetrate for about 3 minutes, then scrub and wipe dry. For heavy soil, I use a 1:4 dilution ratio. This step is crucial for ensuring the surface is pristine before I polish concrete floors.

Initial Grinding and Leveling with BANDě Tools

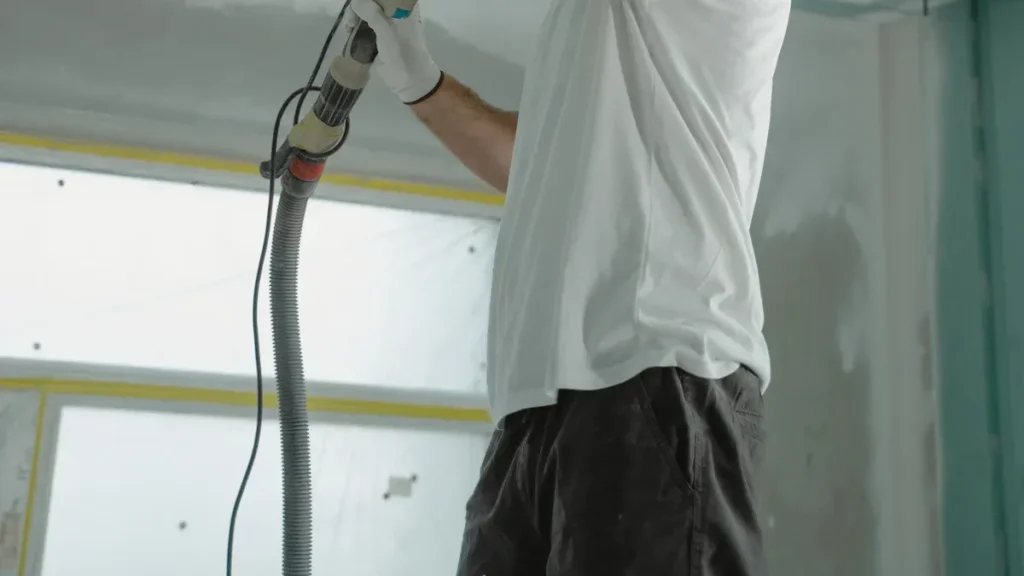

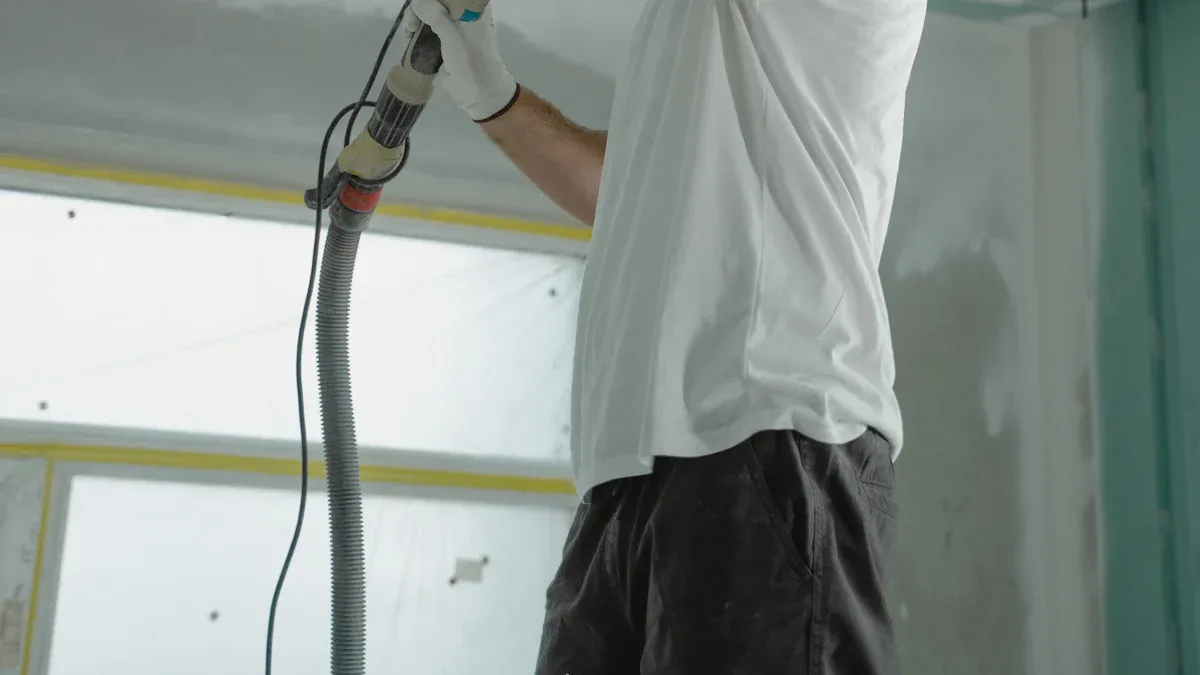

Finally, I begin the initial concrete grinding to level the floor. For smaller areas or edges, I use single-head grinders. For larger spaces, I might opt for a three-headed planetary grinder, which is versatile for both grinding and polishing. I also consider tools like turbo cup wheels for aggressive leveling and removing coatings, or double row cup wheels for general-purpose grinding around drains. Safety is paramount here; I always wear ANSI Z87.1 safety glasses, a NIOSH-approved respirator for silica dust, earplugs, and steel-toe boots. I make sure my grinding tools have wheel guards and that all my PPE fits properly.

The BANDě Step-by-Step Concrete Polishing Process

Now that I have a perfectly prepared surface, I’m ready to dive into the exciting part: the actual concrete polishing! This is where the magic happens, transforming dull concrete into a stunning, polished concrete floor. This step-by-step guide will show you how I achieve that professional look using BANDě products.

Coarse Grinding with BANDě Metal-Bond Diamonds

My concrete polishing journey always begins with coarse grinding. I use BANDě metal-bond diamonds for this initial phase. These aggressive tools are perfect for removing any remaining imperfections, opening up the concrete’s pores, and establishing the foundation for a smooth finish. I typically start with a 30/40 grit diamond, making sure to cover the entire concrete flooring evenly. Then, I move to a 60/80 grit. This progression helps to refine the scratch pattern from the previous pass. I always work systematically, overlapping each pass slightly to ensure uniform coverage. Dust control is crucial here; I connect my grinder to a powerful dust extractor to keep the air clean and visibility clear.

Applying BANDě Concrete Densifier

After my coarse grinding steps, it’s time to strengthen the concrete. I apply BANDě Concrete Densifier. This product penetrates the concrete, reacting with the free lime to create a denser, harder surface. Think of it as making the concrete itself stronger and more resistant to wear. I apply it generously, ensuring the entire floor is saturated. I let it dwell for the recommended time, usually allowing it to soak in completely. This step is vital for achieving a durable and long-lasting polished finish. It also helps the concrete accept the subsequent polishing steps more effectively.

Intermediate Grinding with BANDě Hybrid Pads

With the densifier cured, I transition to intermediate grinding. For this, I switch to BANDě hybrid pads. These pads combine the aggressiveness of metal bonds with the flexibility of resin bonds, making them ideal for smoothing out the surface after densification. I typically start with a 100/120 grit hybrid pad, followed by a 200/220 grit. Each pass removes the scratch pattern from the previous grit, gradually bringing out the concrete’s natural beauty. I pay close attention to consistency, ensuring I don’t skip any areas. This stage is critical for preparing the floor for the final polishing steps.

Fine Polishing for Desired Sheen with BANDě Resin Pads

This is where I truly bring out the shine! For fine polishing, I use BANDě resin pads. These pads are designed to create the desired sheen, from a satin look to a high-gloss mirror finish. I work through a series of progressively finer grits: 400, 800, 1500, and sometimes even 3000. Each grit refines the surface further, increasing the reflectivity. I move slowly and deliberately, allowing the pads to do their work. The more passes I make with the finer grits, the higher the gloss I achieve. It’s incredibly satisfying to watch the concrete transform into a beautifully polished surface right before my eyes.

Applying Protective Coatings and Sealants

My final step in this step-by-step guide is to protect the newly polished concrete. I always apply a high-quality protective coating or sealant. This layer guards against stains, abrasions, and moisture, ensuring the polished concrete remains beautiful for years. For concrete sealing, I trust BANDě concrete sealants.

Here’s how I apply them:

I make sure the concrete surface is clean, dry, and free of any contaminants.

I apply the sealant evenly using a sprayer, roller, or brush, depending on the product and the size of the area.

I allow the first coat to dry completely before applying a second coat if necessary.

I always avoid over-application, which can lead to a slippery surface or an uneven finish.

BANDě concrete sealants typically require reapplication every 3-5 years. This depends on factors like traffic, weather exposure, and the specific product I’m using. High-traffic areas or harsh weather conditions might mean I need to reapply more frequently. This concrete sealing step is essential for maintaining the floor’s integrity and its stunning appearance.

Achieve stunning polished concrete floors! BANDě Products make it easy to polish concrete floors, giving you durable, beautiful concrete flooring. Polished concrete results are within reach! Explore BANDě for your next concrete flooring project. Get that professional look! ✨

FAQ

How often should I polish my concrete floors?

I recommend regularly polishing concrete floors, especially in high-traffic areas. This keeps them looking their best and extends their life.

Can I really do this myself?

Absolutely! With BANDě products and my guide, you can achieve professional results. Just follow the steps carefully.

What if I have really old, damaged concrete?

Don’t worry! BANDě products are designed for various conditions. Focus on proper preparation, and you will see amazing transformations.

See Also

BANDě Concrete Sealer: Your Ultimate Guide To Choosing The Best For 2025

BANDě’s Guide: Essential Concrete Dustproofer Sealers You Absolutely Need

Concrete Sealer: Ultimate Guide To Protecting Your Industrial Floors Effectively

Selecting A Top-Tier Crystal Concrete Floor Polishing Service With BANDě

How BANDě Concrete Densifier Works: A Comprehensive Guide Explained