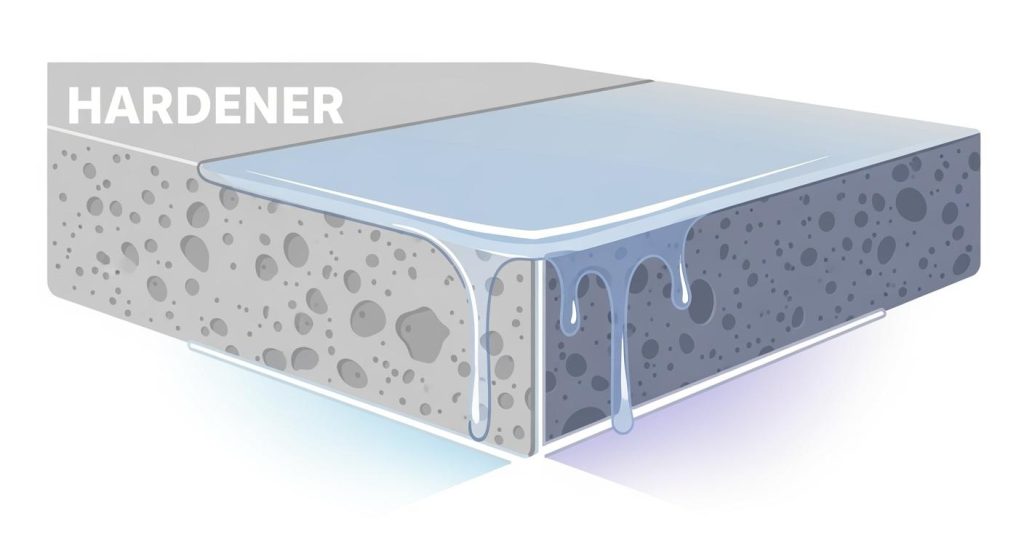

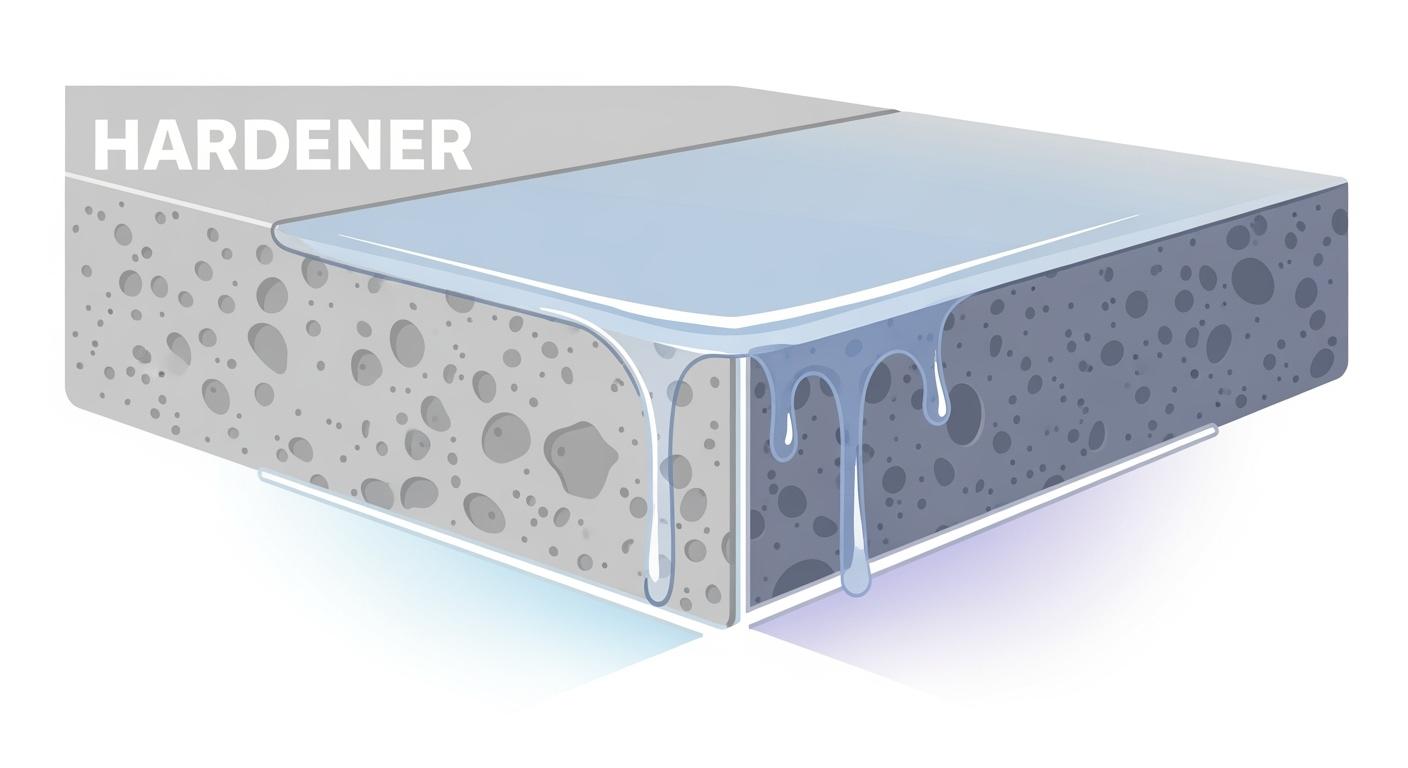

A concrete surface hardener is a chemical solution. It penetrates concrete to increase its hardness and reduce porosity. This concrete surface hardener initiates a chemical reaction within the concrete itself, creating a denser, stronger surface. A concrete hardener enhances durability, reduces dusting, and improves resistance to wear and abrasion. This hardener makes the concrete surface tougher. Concrete hardeners are truly valuable.

Key Takeaways

Concrete hardeners are special liquids or powders. They go into concrete and react with a part of it called calcium hydroxide. This reaction makes the concrete much stronger and harder.

The hardener creates a new material inside the concrete. This material fills tiny holes. This makes the concrete surface very dense and stops it from dusting or wearing away easily.

Applying hardeners correctly is important. You must clean the concrete first. Then, you apply the hardener evenly. Proper drying and care after applying the hardener make the concrete last a very long time.

How Concrete Hardeners Chemically Transform Surfaces

Concrete’s Internal Chemistry and Reactivity

Concrete might seem like a simple, solid material, but it actually has a complex internal chemistry. When cement mixes with water, it creates a hydration process. This process leaves behind a byproduct called calcium hydroxide. This calcium hydroxide is a key player in how a concrete hardener works. Concrete hardeners are typically liquid solutions. They penetrate the concrete surface, soaking into its pores and reacting with these internal chemicals. Concrete densifiers, a type of surface hardener, react with calcium hydroxide within the concrete. This chemical reaction forms calcium silicate hydrate (CSH), which densifies and hardens the concrete. Concrete hardeners are chemicals, including certain fluorosilicates or sodium silicate, applied to concrete floors to reduce wear and dusting.

The Calcium Hydroxide Reaction in Hardening Concrete

The magic truly happens when the hardener meets the calcium hydroxide. This chemical reaction is the core of the hardening process. Calcium hydroxide, also known as free lime, reacts with silicate-based hardeners. These include colloidal densifiers, sodium silicate densifiers, and general concrete densifiers. This chemical reaction produces calcium silicate hydrate (C-S-H). This C-S-H is crucial for increasing the concrete’s strength, density, and durability. It achieves this by filling pores and microcracks. Specific products like CCS Formula CSH-150 are designed to rapidly react with calcium hydroxide within the concrete’s capillaries and canals. This reaction strengthens and binds the concrete. It results in a denser, harder, and more closed-off surface. This enhances the depth, clarity, and reflection of polished concrete with less grinding.

Forming C-S-H Gel for Concrete Densification

The newly formed C-S-H gel is a game-changer for the concrete. This gel fills the tiny pores and voids within the concrete structure. Imagine it like glue filling all the gaps. This process leads to a much denser, harder, and less porous surface. Experts often call this process “densification.” This densification makes the concrete much more resistant to wear and tear. It also helps protect the surface from various types of damage. The hardener essentially transforms the concrete from within, creating a stronger, more resilient material.

Types of Concrete Surface Hardeners and Their Action

Silicate-Based Concrete Hardeners: Liquid Solutions

Concrete surface hardener products come in various forms. Liquid hardeners are often silicate-based. These include sodium, potassium, and lithium silicates. The primary role of the sodium, potassium, or lithium component within the silicate is to stabilise and solubilise the silicate. This allows the silicate to remain in solution until it can penetrate concrete and react with the abundant calcium hydroxide present. These ions generally do not react significantly within the concrete itself. Lithium silicate is an ionic compound where lithium serves as a transport agent for silica. Different silicates have varying molecular sizes. Lithium silicate has the smallest molecular size, allowing for deeper and more even penetration into concrete, even tight finishes. Colloidal silica, another type of concrete hardener, also has small particles (nanosilica). It offers excellent penetration, even into hardened concrete, and is more reactive.

Dry Shake Hardeners: Powdered Surface Treatments

Another type of hardener is the dry shake hardener. These are factory-blended powders. They contain cementitious binders, aggregates, and admixtures. Workers apply them to fresh concrete. For example, Metz Korodur Dry-Shake Topping uses ‘Korodur 0/4 hard aggregate’. This aggregate blends with Portland cement to improve the abrasion and impact resistance of concrete floors. Nitoflor Sicaltop, another dry shake-on floor hardener, incorporates ‘silicon carbide / alumina additive’. This provides a non-rusting, extremely hard-wearing, and slip-resistant surface. For best results, a mechanical application rate of 5 kg/m² is recommended for dry shake colour hardeners. Lower application rates are not advised.

Key Benefits of a Hardened Concrete Surface

A hardened concrete surface offers many advantages. It significantly increases abrasion resistance. Concrete hardeners also reduce dusting. They impregnate capillary spaces and chemically react with free lime. This bonds and strengthens the crystalline structure. Raw concrete floors wear down easily, creating dust. Hardeners create a smooth finish that resists dust production. This keeps the environment cleaner. Densifiers penetrate deep into the concrete surface. They increase the surface strength of concrete by up to 40%. This dramatically increases abrasion resistance and surface compressive strength, helping to reduce dusting. Furthermore, a concrete hardener improves resistance to chemical attack. Products like Cementaid Diamite Surface Hardener enhance the surface of concrete. This increases its resistance to chemical and acid attacks. Aardcure Catalyst reduces the permeability of concrete. This improves its resistance to chemical attack.

How to Apply a Concrete Hardener for Best Results

Essential Surface Preparation for Hardener Application

Before you apply a concrete hardener, proper preparation is crucial. The concrete surface must be clean, dry, and free from anything that could stop the hardener from penetrating. This means removing dust, dirt, grease, oil, and any other contaminants. You also need to clear away frost, laitance, surface water, coatings, and all loosely adhering particles. A clean surface ensures the hardener can react effectively with the concrete.

Effective Application Techniques for Concrete Hardening

When you apply the hardener, the method depends on the type. For liquid hardeners, people often use spraying or mopping. You should ensure even coverage across the entire surface. Dry shake hardeners, on the other hand, are powders. Workers spread these evenly onto fresh concrete. It is important to follow the manufacturer’s recommended coverage rates. Also, keep the hardener wet on the surface for the specified time. This allows for the full chemical reaction to take place, ensuring the hardeners work as intended.

Maximising Durability and Longevity of Treated Concrete

To truly maximise the durability and longevity of your treated concrete, proper curing after application is vital. Curing methods aim to minimise moisture loss from the concrete. This can involve covering it with an impermeable membrane or continuously wetting the exposed surface. For instance, leaving formwork in place or using plastic sheeting effectively prevents water loss. Membrane-forming curing compounds also create a barrier. Water curing, like ponding or sprinkling, continuously supplies moisture. Proper curing makes the concrete stronger and more resistant to stress, abrasion, and frost. It also makes the concrete more impermeable, preventing moisture and water-borne chemicals from entering. This significantly increases the durability and service life of the concrete hardener treatment. When you apply a concrete hardener, remember that good curing protects the surface from sun and wind, enhancing its overall performance. This final step ensures the hardener provides lasting benefits.

Ultimately, concrete hardeners chemically react with calcium hydroxide within the concrete. This forms a dense, crystalline C-S-H gel, effectively filling pores and strengthening the surface. This process helps to effectively strengthen concrete floors. A concrete surface hardener enhances durability, reduces dusting, and improves wear resistance. This hardener helps extend the life of concrete floors, making the concrete more robust.

FAQ

How long does a concrete hardener last?

Concrete hardeners offer permanent benefits. They chemically react with the concrete, becoming an integral part of the surface. This means the hardening effect lasts for the lifetime of the concrete itself.

Can you apply concrete hardener to old concrete?

Yes, you can apply liquid hardeners to existing concrete. The surface must be clean, dry, and free from sealers or contaminants for the best penetration and reaction.

Are concrete hardeners safe for the environment?

Many modern concrete hardeners are water-based and low in VOCs (Volatile Organic Compounds). They are generally considered safe for the environment once cured, posing minimal risk.

See Also

Unveiling The True Distinction: Concrete Densifiers Versus Hardeners Explained

Understanding BANDě Concrete Densifier: Its Functionality And Operational Mechanics

Your Essential Buying Guide: Densifiers, Hardeners, And Sealers For Concrete

A Detailed Guide To BANDě Concrete Densifier’s Operational Principles

Industrial Floor Hardeners: An In-Depth Comparative Analysis For 2025