You’re seeing a big jump in interest for inorganic seven-color wall coatings in the U.S. market. BANDě Inorganic Seven-Color Wall Coating leads this innovative trend. What makes this specific wall coating so appealing? What’s crucial for its successful application on any surface? This coating blends stunning aesthetics, top-notch performance, and sustainability. Proper surface preparation is also key for a perfect finish on your walls. Preparing the surface well ensures the coat adheres beautifully to the surface. A well-prepared surface makes all the difference on your walls.

Key Takeaways

BANDě Inorganic Seven-Color Wall Coating uses natural materials. It makes walls look good and last a long time.

This special wall coating is good for your health. It cleans the air and stops mold from growing.

Proper surface preparation is very important. It helps the coating stick well and last longer.

This coating works for many places. You can use it inside homes, outside buildings, and in factories.

The coating helps the environment. It is a safe choice for building projects.

The Appeal of BANDě Inorganic Seven-Color Wall Coating

Unique Composition for Superior Wall Coating

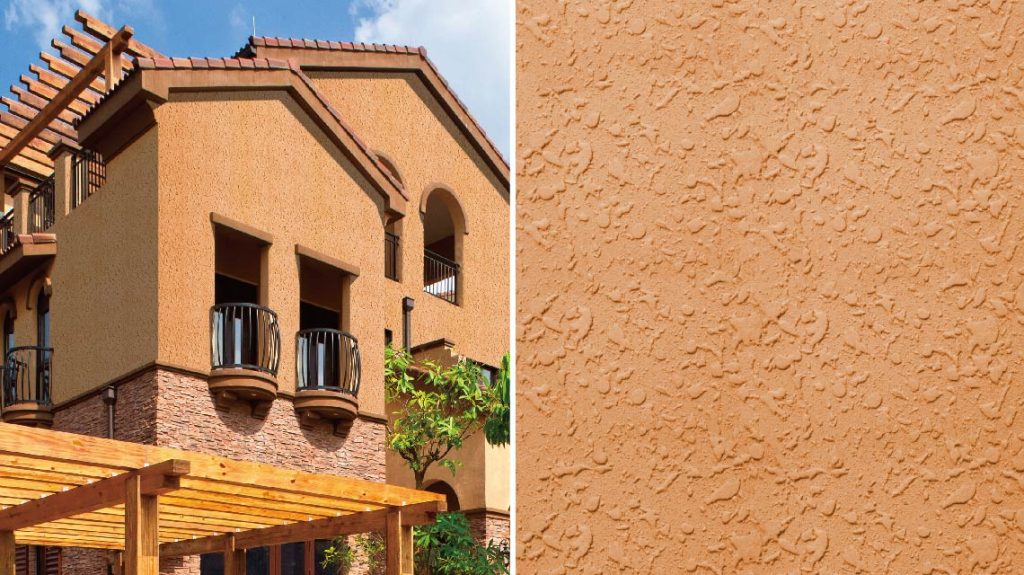

You’re looking for something truly special for your home or business, right? BANDě Inorganic Seven-Color Wall Coating delivers an integrated, customized solution for both interior and exterior walls. This isn’t just any ordinary wall coating; it’s a scientific blend designed for superior performance and aesthetics. We start with natural sand, which acts as the “bone” of the coating, giving it structural integrity and a unique texture. Then, natural fibers become the “skin,” adding flexibility and depth. Inorganic solid colorants also form part of this “skin,” providing rich, stable hues that won’t fade. Finally, BANDě customized auxiliary agents supplement these core ingredients, ensuring everything works together perfectly. This unique composition gives your walls distinctive tones and textures. You’ll notice a difference immediately. This isn’t just a coat; it’s an experience for your surface.

Aesthetic Versatility and High-End Finishes

Imagine transforming your space with a wall coating that offers endless possibilities. BANDě Inorganic Seven-Color Wall Coating lets you achieve a wide range of visual effects. Do you prefer a simple, minimalist look? You can have it. Are you drawn to ancient, rustic charm? This coating creates that too. Perhaps you want something fashionable and modern, or elegant and sophisticated. You can easily achieve these styles. For those who dream of luxurious or magnificent interiors, this wall coating delivers. You can even create fairy-tale-like colorful visual effects that truly captivate. This versatility means you don’t just apply paint; you craft an atmosphere. The unique texture and vibrant colors make every surface a canvas. You get high-end finishes that elevate any room, making your walls a focal point. This innovative wall coating truly redefines what you expect from a finish.

Essential Surface Preparation for Optimal Wall Coating Adhesion

You want your new wall coating to look fantastic and last a long time, right? That starts with excellent surface preparation. Think of it as building a strong foundation. You need to ensure the surface is dry and sound. You must clean it thoroughly, removing mildew, oil, dust, dirt, loose rust, or any other contamination. This crucial step ensures your paint adheres perfectly.

Key Steps to Prep a Room for Painting

To prep a room for painting, you follow several key surface preparation steps. First, you assess the existing surface conditions. Do you see any damage? You need to repair it. For instance, you might grind out cracks and fill them with polymer-modified cement for a sealed repair. You also need to remove loose pebbledash or render and replace it to create a perfect base. Next, you clean your walls thoroughly. Power wash and wire brush away all dirt, mold, and loose paint. Some properties might even need anti-fungal treatment.

Different methods of surface preparation apply to various materials. For metal, you remove corrosion and oxides, perhaps by sandblasting, to improve adhesion. For wood, you clean dust and remove oil and grease. Concrete needs sealing to enhance paint adhesion. For plastic, you increase surface roughness by grinding. After cleaning, you might use sandpaper to create a slightly rough surface, which optimizes coating adhesion. This smoothing process is vital. You must also remove abrasive dust with a final wipe down.

Why Proper Prep is Crucial for Your Wall Coating

Skipping proper surface preparation is a big mistake. Without it, your coatings are prone to peeling, blistering, and flaking. This significantly reduces their lifespan. Inadequate prep leads to premature failures. Contaminants like dirt, oil, rust, or moisture create weak points. These weak points result in corrosion, cracking, or bubbling. If you leave “interference” material like oil, grease, dirt, or even invisible soluble salt contamination on a surface, the coating may not properly contact and adhere to the substrate. This leads to a loss of adhesion in the form of blistering or delamination. Neglecting proper surface preparation can lead to costly rework and potential safety hazards. A poorly prepared surface compromises the coating’s ability to handle environmental exposure, abrasion, and chemical contact stresses. This reduces its durability and functional lifespan.

Addressing Common Surface Challenges Before Coating

You will encounter common challenges when you prepare a room for painting. Delamination, or peeling off, often happens due to inadequate surface preparation. A smooth or dirty substrate leads to weak adhesion. To fix this, you remove all loose coating. Then, you abrasive blast or use sandpaper to get a clean, roughened surface. You apply an appropriate primer to promote strong adhesion. Poor adhesion also stems from a lack of proper surface preparation. You must always start with proper surface preparation, following industry guidelines. You remove all rust, old loose paint, and grease. You ensure the surface profile meets the coating manufacturer’s specifications.

For difficult surfaces or critical service, you use high-quality primer and adhesion promoters. Primers are essential for creating a robust bond. If abrasive blasting isn’t possible, adhesion promoters can improve bonding without mechanical profiling. You might also face challenges with environmental conditions during application and curing. You must control the application environment. Ambient temperature, surface temperature, humidity, and dew point must be within acceptable ranges for painting. You avoid painting if the surface is colder than the dew point or excessively hot. You also need to prepare new plaster for painting by ensuring it’s fully cured. If you need to prepare walls after removing wallpaper, you must clean off all paste residue and repair any holes or cracks with filler before painting. You might use filler for small imperfections. You also need to remove surface contaminants like dust and particles after profiling. You blow them off and vacuum them. Even tiny debris can get in the way of adhesion. These methods of surface preparation ensure a lasting finish.

Performance Benefits Driving Inorganic Wall Coating Popularity

You want your living or working space to be safe, durable, and efficient, right? Inorganic seven-color wall coating offers significant advantages that meet these modern demands. This isn’t just about aesthetics; it’s about superior performance that benefits you and your environment.

Health and Environmental Advantages of Inorganic Coatings

You care about the air you breathe and the health of your family. Unlike conventional paints, which often release volatile organic compounds (VOCs), heavy metals, and even formaldehyde for years, inorganic coatings are different. They contain no organic solvents, heavy metals, or harmful volatile compounds. This means you get a healthier indoor environment. You won’t worry about toxic effects like respiratory problems or damage to organs that conventional paints can cause.

Inorganic coatings actively purify the air. They decompose harmful substances like formaldehyde and benzene. They also eliminate indoor odors. Many conventional paints only adsorb formaldehyde, which can re-release when saturated. This inorganic wall coating works differently. It provides excellent antibacterial and mold-resistant properties, resisting over 99.9% of viruses. Its alkaline nature kills bacteria and mold spores. Mold growth releases spores, posing health risks, especially for vulnerable individuals. This coating helps prevent that. You also get peace of mind with its fire resistance. It meets the A1 fire resistance standard, meaning it is non-combustible. It does not generate large amounts of smoke or toxic gases during a fire. Conventional paints can make fire hazards worse. This inorganic coat benefits the health of everyone in your home or business. It also lasts a long time, often for the same lifespan as your walls, resisting peeling, cracking, and fading.

Enhanced Durability and Protection for Walls

You need your walls to withstand the test of time and the elements. Inorganic nanoceramic coatings have a dense molecular structure and chemical composition. This makes them highly impermeable to moisture, chemicals, acids, solvents, and alkalis. They create a robust protective barrier on any surface. Unlike organic coatings that may contain VOCs and hazardous materials, inorganic nanoceramic coatings are typically water-based. They are free from toxic substances, making them environmentally friendly and safer for your surface.

These inorganic coatings are water-resistant and breathable. They allow internal moisture to evaporate while preventing external water from getting in. Think of it like human skin. This keeps your walls dry and prevents issues like static electricity attracting dust. This offers anti-fouling properties for the coated surface. Inorganic coatings also have alkaline properties. These provide antibacterial and anti-mold benefits. They resist various strains of bacteria, like Escherichia coli and Staphylococcus aureus. They also inhibit the growth of moss, algae, and microbacteria because they do not contain nutrients. Organic coatings, in contrast, can form a film on walls that may lead to hollow drums, blistering, or peeling over time. Zinc Oxide (ZnO) is a widely used inorganic material in coatings. It prevents microorganisms like mold and mildew from establishing colonies and causing discoloration, even in the presence of water on the surface. This ensures a cleaner, more durable surface.

Functional Superiority: Air Purification and Insulation

You want your space to be comfortable and clean. Inorganic wall coatings offer functional superiority beyond just protection. They actively purify the air. For example, iron oxide nanowires act as antimicrobial agents. They inactivate bacteria, such as Staphylococcus epidermidis, by generating hydroxyl radicals when reacting with oxygen and water in the air. This helps keep the air on your surface cleaner. Inorganic membrane coatings on ceramic filters also enhance particulate matter (PM) removal. They achieve high filtration efficiencies, for example, 98% for PM10 and 97.7% for PM2.5. Additionally, photocatalysts like Cu2O-TiO2, when coated on a surface, decompose volatile organic compounds (VOCs). They do this by generating reactive oxygen species (ROS) under ambient conditions. This means the coating on your surface is working to improve air quality.

When it comes to insulation, you might wonder about R-values. Inorganic wall coatings, such as heat-reflective paints or insulation coatings, are generally not assigned an R-value. The R-value system is a standardized measurement. It is primarily for bulk insulation materials like fiberglass or foam. These materials are designed for thermal resistance. While some specialized insulating paints exist with additives like ceramic microspheres, their insulating capabilities are not quantified using the R-value system. The effectiveness of these paints is often limited compared to traditional insulation materials. Their performance is influenced by various factors not easily captured by a standardized R-value. Paints are typically thin coatings. They are not primarily designed for insulation. Their composition and thickness are generally insufficient for significant thermal resistance on a large surface area. Painted surfaces are subject to variable environmental conditions. These include temperature, moisture, and sunlight. These conditions can affect thermal properties, making a consistent R-value challenging to assign to the surface.

Application and Market Impact of Inorganic Wall Coating

Versatile Applications Across Various Settings

You can use inorganic seven-color wall coating in so many places! Think about your home, factories, hospitals, schools, warehouses, tunnels, subways, air defense sites, and basements. This versatile coat works on rigid substrates, offering great durability and corrosion resistance. For outdoor environments, you get excellent weather resistance. If you need to protect industrial equipment, you’ll find its abrasion resistance outstanding. Even in marine settings, this paint provides superior weather and abrasion resistance.

Meeting Modern Demands for Sustainable Wall Solutions

You see a big push for sustainable building materials today. Inorganic coatings meet this demand perfectly. Urbanization, new environmental regulations, and a desire for durable, eco-friendly construction materials drive their popularity. Government policies promote sustainable construction. Strict environmental rules favor eco-friendly and low-VOC coatings. Innovations in biodegradable and low-VOC inorganic formulations align with these standards. This makes them ideal for green building projects and sustainable urban development. You also benefit from energy-efficient buildings, which save up to 30% on energy costs. North America, especially the U.S., leads this growth due to stringent building codes and a focus on energy-efficient construction practices. Customers want eco-friendly, fire-resistant, and moisture-resistant paint options. This reflects a shift towards safer and more sustainable building practices.

Professional Considerations for Inorganic Coating Application

Applying inorganic coatings requires careful attention. You should only apply them when the temperature is above 10°C and humidity is below 85%. Avoid outdoor painting on rainy days. For optimal results, you need proper surface preparation. This ensures the paint adheres correctly to the surface. Specialized techniques like E-Coat, PVD Coating, and CVD are used for specific industrial applications, offering comprehensive coverage and enhanced durability. For your walls, especially if you have weak putty, we recommend using BANDě powder-based alkali-resistant primer, particularly Type I. This primer strengthens the surface, improves water resistance, and ensures uniform absorption for the final paint. It prevents peeling and cracking of the inorganic topcoat. A high-quality primer is crucial for a lasting finish. It also helps reduce salt precipitation on the surface. You must ensure thorough surface preparation before any painting. This includes removing all loose paint and ensuring the surface is clean. Proper surface preparation makes all the difference for your paint job.

You now understand why BANDě Inorganic Seven-Color Wall Coating is revolutionizing the market. Its unique composition delivers stunning aesthetics and comprehensive benefits, solving many common wall challenges. Remember, proper surface preparation is absolutely critical. It unlocks the coating’s full potential, ensuring long-term success on any surface. This innovative solution, combined with diligent surface preparation, offers a superior choice for your modern construction and renovation projects. You can expect continued growth and impact on the U.S. wall coating market. Consider this advanced coating for your next project; it truly transforms every surface. This coating protects your surface, making it beautiful. You will love the finish on your surface. The coating adheres perfectly to the surface. This ensures a durable surface. A well-prepared surface is key.

FAQ

What makes BANDě Inorganic Seven-Color Wall Coating different from regular paint?

This coating uses a unique blend of natural sand, fibers, and inorganic colorants. It offers superior durability, air purification, and mold resistance. You get a healthier, longer-lasting finish than with traditional paints.

Is this coating safe for my family and pets?

Yes, it is very safe! This coating contains no VOCs, heavy metals, or harmful compounds. It even purifies the air and resists mold. You get a healthier indoor environment for everyone.

Can I use this coating on exterior walls?

Absolutely! This coating works for both interior and exterior walls. It offers excellent weather resistance. Just remember to apply it when the temperature is above 10°C and humidity is below 85%.

How long can I expect this coating to last?

You can expect great durability. This inorganic coating often lasts as long as your walls. It resists peeling, cracking, and fading. Proper surface preparation helps ensure its long lifespan.

Do I need a special primer before applying this coating?

Yes, you do! We recommend BANDě powder-based alkali-resistant primer, especially Type I for weak putty. This primer strengthens your surface and ensures the topcoat adheres perfectly.

See Also

Discovering Inorganic Anion Wall Paint: Your Path To Healthier Homes In 2025

Achieve Durable Finishes: Unveiling The Advantages Of Inorganic Anti-Alkali Primer

Industrial Floor Hardeners: An In-Depth Comparative Analysis For The Year 2025

Your Ultimate Buying Guide To Concrete Densifiers, Hardeners, And Sealers

Top Floor Hardener Solutions For Industrial Warehouses Across The United Kingdom