Tired of the same old problem? Many face this frustrating problem. Temporary fixes mask the real problem. This post offers a permanent solution. It guides effective problem solving for your driveway’s crack problem, addressing its root cause. This ensures a lasting solution, stopping recurring problems.

Key Takeaways

Fixing driveway cracks for good means finding out why they started. This stops them from coming back.

Use the right materials and put them on correctly. This makes your driveway repair last a long time.

Taking care of your driveway regularly helps it stay strong. This saves you money and worry later.

Defining a Permanent Solution: Beyond Quick Fixes

Many people often find themselves stuck in a cycle of temporary fixes. They patch a driveway crack, only to see it reappear months later. A true permanent solution, however, completely resolves the underlying problem. It eliminates the root cause and prevents any further recurrence. This approach requires thorough thinking and exploration rather than rushing into another quick patch. It means looking deeper into the issue to find a lasting answer.

Identifying the True Root Cause

Finding a permanent solution begins with identifying the true root cause of the problem. You cannot fix something for good if you do not know why it broke in the first place. For driveway cracks, this means going beyond the visible line on the surface. A proper root cause analysis helps uncover the real culprits. Many factors contribute to driveway problems.

Common underlying causes of driveway cracks include various issues. Weather conditions play a big role, especially freeze-thaw cycles and extreme heat. Poor installation or substandard materials often lead to early failure. Heavy loads and constant vehicle traffic also stress the pavement. Tree roots growing underneath can exert pressure and cause cracks. Soil movement or settling beneath the driveway creates instability. Poor drainage is another significant problem. Water pooling near a driveway or seeping into its foundation accelerates damage. When water-damaged soil beneath a foundation creates voids due to erosion, uneven settling occurs. This leads to sinking and cracking. Water infiltration, particularly during freeze-thaw cycles, frequently causes driveway cracks. Understanding these factors is crucial for effective problem solving. This detailed analysis helps pinpoint the exact reason for the problem.

Preventing Future Incidents

Once you identify the root cause through careful analysis, the next step involves implementing strategies to prevent future incidents. A permanent solution means the problem does not return. This requires a proactive approach to driveway maintenance and design. Effective process improvement ensures the conditions that led to the initial problem no longer exist.

Several methods effectively prevent future driveway crack incidents. Regular cleaning helps remove dirt and debris that can break down materials. Timely crack repair, even small ones, stops them from growing larger. Checking drainage is vital. Ensure rainwater and melted snow flow away from the driveway. If water pools due to an improper slope, consider fixing it. Controlling vegetation also helps. Remove or relocate trees with roots near the surface. These roots can exert pressure and cause cracks. For larger trees, installing root barrier systems offers a solution. Maintaining joints by replacing cracked caulk prevents water penetration. Applying a penetrating sealer every few years repels water and oil, extending the driveway’s life. These steps are part of a comprehensive problem solving strategy to prevent recurrence.

Achieving a Definitive End

Achieving a definitive end to your driveway crack problem brings numerous long-term benefits. This is where the value of a permanent solution truly shines. It means you no longer worry about recurring damage or constant repairs. This type of corrective action provides lasting peace of mind.

Addressing the root cause offers significant advantages. It can increase property value, with quality driveway repairs potentially boosting home values. It prevents future damage by blocking destructive plant growth and shielding the foundation from water. This approach also leads to substantial cost savings. Expert repairs cost less than full driveway replacement in the long run. Professional materials and techniques can double or triple the normal concrete lifespan. Regular maintenance with professional sealing extends concrete life significantly. Furthermore, repairing cracks eliminates tripping hazards, improving safety. Maintaining the structural integrity of the driveway prevents small problems from growing into major structural threats. This comprehensive approach ensures a lasting resolution and represents a true improvement.

Implementing Your Lasting Driveway Solution

You have identified the root cause of your driveway’s recurring cracks. Now, you are ready to implement a lasting solution. This section guides you through the practical steps. It ensures your repair stands the test of time.

Preparing for a Durable Repair

A successful, long-lasting repair starts with thorough preparation. You cannot skip these crucial steps. They ensure the repair materials bond correctly and effectively.

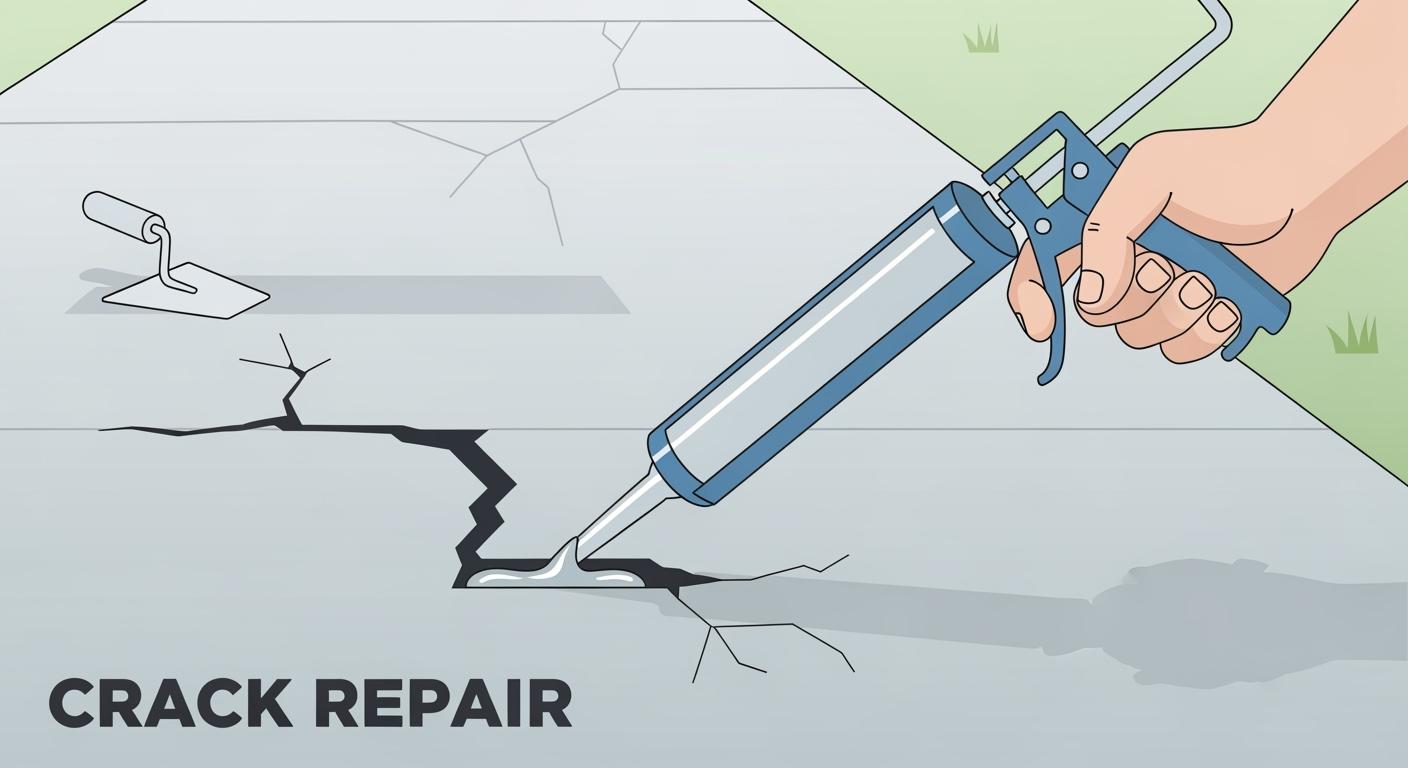

First, you must clean the affected area. Remove any broken asphalt pieces that obstruct the crack. A hammer and chisel work well for this. Next, use a wire brush or a wire wheel on a drill. This helps you thoroughly remove dirt and debris from inside the crack. Finally, use a compressed air gun or a shop vacuum. This eliminates all loose debris and smaller particles. If you do not have these tools, a garden hose can flush out the crack. Just make sure the crack dries completely afterward. Always wear safety goggles to protect your eyes from debris, regardless of the cleaning method.

After cleaning, you might need to widen the cracks. This step is important for proper material adhesion. For most repairs, a routing width of approximately 6-12mm works best. This width allows for proper backer rod installation. It also provides enough sealant volume for flexibility and durability. Medium cracks, those between 3-6mm, often need routing. This creates the correct geometry for sealant application. A wider opening enhances sealant penetration. It also increases the adhesion surface area. If cracks exceed 1/8-inch or bear heavy loads, consider an epoxy injection or semi-rigid polyurethane system. These systems comply with ASTM C881 bonding-agent standards. Epoxies offer structural strength. Semi-rigid materials maintain flexibility for thermal cycling in warehouse floors. This careful preparation prevents a recurring problem. It sets the stage for a robust repair process.

Selecting the Right Permanent Materials

Choosing the right materials is key to a permanent resolution. Not all fillers and sealants offer the same durability. You want options that address the root cause and last for years.

Several types of permanent driveway crack fillers exist. Coal tar crack fillers are affordable. However, they emit toxic VOCs, degrade in UV light, and can stain. Their use is declining due to environmental concerns. Asphalt-based crack fillers offer a safer, more eco-friendly alternative. They are also affordable and durable. You can find them in bulk or as filler ropes. Like coal tar, they are vulnerable to UV degradation and solvent staining. Epoxy and acrylic crack fillers are similar. They provide UV protection, a longer lifespan, and resistance to oil or gas stains. Epoxy is generally thicker, lasts longer, and costs more than acrylic. People prefer them in hot climates due to superior UV protection. They provide a longer-lasting seal, though they are pricier than coal tar or asphalt products.

Consider asphalt emulsion sealers for overall protection. This sealant, made from asphalt and water, protects pavement from weathering and oxidation. It is a modern improvement over older coal tar sealers. It is significantly more eco-friendly and healthier. Homeowners often prefer asphalt emulsion because it dries to a smooth, true black finish. This differs from the dark gray shade of tar-based products. Its deep black color comes from its composition of asphalt blended with small amounts of water and emulsifying agents.

Asphalt emulsion sealers offer many benefits:

Low odor and low VOCs: They are neighborhood-friendly. Chemical fumes are less of a concern.

Easier clean-up: You can clean tools and skin with water.

Environmentally gentle: They produce less toxic runoff. This aligns with green project goals.

Flexible finish: The material moves with asphalt during temperature changes. This helps prevent cracking.

Dries to a rich, deep black: It restores the appearance of new pavement.

However, they have some drawbacks. They offer less chemical resistance. Spills like gasoline or oil can cause damage. They also have a slower drying time. It takes longer before you can open the area to traffic. They might also be less durable in extreme climates. They might not last as long under heavy traffic or intense sun. These sealers work best for residential driveways, walking paths, and parking lots in moderate climates. They are also ideal for projects where environmental impact or odor are primary considerations. This careful selection of materials is a critical step in your problem solving process.

Applying the BANDě Solution for a Permanent Resolution

The BANDě solution offers a robust approach to achieving a permanent solution for your driveway cracks. This silicone adhesive tape provides optimal adhesion and longevity when applied correctly.

Follow these specific application instructions for the best results:

Surface Preparation: Ensure the surface is clean, dry, and free of contaminants. This includes dust, oil, or grease. Use isopropyl alcohol (IPA) or a recommended solvent for cleaning. If surfaces are glossy, abrade them to improve mechanical adhesion. Crucially, avoid touching the adhesive side with bare hands.

Measuring and Cutting: Precisely measure the area. Add 10–15% extra length for overlap. Use sharp tools for clean cuts. Avoid stretching or jagged edges. For curved surfaces, consider using narrow or segmented pieces.

Application Technique: Peel back a small section of the liner. Align the tape and apply it with firm, even pressure. Apply slight tension (5–10%) to prevent wrinkles. Use a roller or squeegee to eliminate air bubbles and enhance contact. Remember, full bond strength develops over 24-72 hours.

Sealing Edges: Press down all edges firmly with a fingertip or tool. For critical seals, consider a second strip or seam sealant. Inspect for gaps, especially in high-movement areas.

Testing Adhesion: After 24 hours, gently check for lifting. Inspect for uniform contact without gaps or bubbles. For high-stress applications, perform a pull test. If adhesion fails, re-clean and reapply. Do not attempt to re-stick.

This meticulous application process ensures the BANDě solution provides a lasting fix. It tackles the problem directly, offering a durable repair.

Ensuring Long-Term Durability

Your driveway repair is not complete after applying the materials. Ensuring long-term durability requires proper curing, sealing, and ongoing preventative measures. This protects your investment and extends the life of your repair.

Allow sufficient drying time as per manufacturer instructions. This is crucial for the materials to cure properly. After curing, apply a high-quality sealant. This protects against moisture, chemicals, and traffic. You should apply the product evenly with recommended tools for uniform coverage. Schedule re-application every few years. This depends on wear and environmental factors. Regularly sweep debris off the surface. This prevents scratches and staining. Avoid using harsh chemicals. They can strip away the sealant’s properties. Inspect for new cracks. This allows for immediate attention. It preserves the integrity of previously completed driveway repair efforts.

Proper timing for crack seal upkeep is also important. Perform maintenance during spring and fall. Temperatures are moderate then. This ensures proper adhesion and curing. Use a high-quality, rubberized asphalt crack sealant. It can expand and contract with temperature changes. Also, use a reliable sealer for surface protection. Essential tools include a crack cleaning machine, router, and sealant applicator.

Avoid common mistakes. Do not ignore small cracks. They can quickly worsen. Improper cleaning of cracks prevents proper adhesion. Overfilling or underfilling cracks leads to ineffectiveness. Do not seal in poor weather conditions, such as extreme temperatures or rain. Avoid using low-quality materials. They can lead to premature repair failure.

This comprehensive approach to maintenance is a continuous process. It represents a significant process improvement over reactive repairs. Regular inspections catch potential issues early. This prevents them from becoming larger problems. Sealcoat every few years. This protects against UV rays, oxidation, water penetration, and chemical spills. Ensure proper drainage solutions. This prevents standing water from seeping into the asphalt base. It stops premature deterioration. Regular maintenance, including sealcoating, cleaning, and drainage monitoring, reduces crack and pothole formation. Promptly address minor issues. This prevents them from escalating into major repairs. Use high-quality materials and application methods. They withstand environmental stressors. Clean your driveway at least twice a year. This is after winter and summer. More frequent light cleanings are good during heavy leaf fall or pollen seasons. Inspect regularly to detect small cracks and dips early. Address them promptly. This maintains surface integrity and safety. This proactive approach leads to a lasting improvement.

Investing time in a permanent solution brings lasting peace of mind and saves money. You learned to fix the problem by understanding its root cause, choosing the right materials, and applying them correctly. This problem solving approach extends beyond your driveway. Apply this definitive problem solving mindset to other life problems, tackling each problem with confidence. Enjoy a future free from driveway problems, thanks to your lasting solution.

FAQ

How long does a permanent repair last?

A properly executed permanent repair can last many years. It often outlasts temporary fixes by a significant margin. Regular maintenance helps extend its lifespan even further. 🛠️

Can I do this repair myself?

Many homeowners can successfully complete this repair. They need to follow instructions carefully. Proper preparation and material application are key for a lasting result. 💪

What if my cracks are very wide?

Very wide cracks might require professional assessment. They could indicate deeper structural issues. A professional can recommend the best approach for these larger problems. 🧐

See Also

Prevent Costly Concrete Damage: Simple Solutions for Fixing Small Cracks Effectively

Essential Concrete Patching Compounds: Top Choices for Durable Repairs in 2025

Achieve Permanent Fixes: Your Comprehensive Guide to Mastering Cement Crack Sealers

Selecting the Perfect Cementitious Crack Sealer: A Guide for All Surfaces

Ditch the Epoxy Mess: Upgrade Your Garage Floor with This Simple Densifier