For most homeowners in 2025, polyaspartic floor coatings generally offer the best overall performance for your residential garage floor. Polyaspartic provides superior durability, making it the best crystal floor hardener for garage applications. This polyaspartic flooring applies faster than epoxy and traditional polyurea. While polyaspartic often wins, your ideal epoxy or polyurea choice depends on your specific needs.

Key Takeaways

Polyaspartic coatings are often the best choice for garage floors. They offer great strength and last a long time.

Epoxy and polyurea coatings are also good options. They work well for different needs and budgets.

Consider your garage use, budget, and local weather. These factors help you pick the right floor coating.

Epoxy Garage Floor Coatings: An Overview

What is Epoxy Coating

Epoxy is a popular choice for garage floor coatings. You mix a resin and a hardener. This creates a tough, plastic-like material. It bonds strongly to your concrete floor. This gives you a seamless, durable surface.

Epoxy Pros and Cons

Epoxy guards your garage floor well. It resists stains, cracks, and general wear much better than plain concrete. Many people use epoxy as an excellent primer. It also works well for vapor barrier applications. However, epoxy can be less flexible. This type of epoxy might also yellow over time if exposed to a lot of sunlight.

Epoxy Cost & Durability

The cost for an epoxy garage floor varies. You can expect to pay between $3 to $12 per square foot. This depends on the type of epoxy and installation complexity. Despite its lower cost compared to some alternatives, epoxy provides good durability. It handles spills and impacts well.

Epoxy Lifespan & Best Uses

A professionally installed epoxy garage floor can offer impressive longevity. While some might say 5-10 years, many high-quality epoxy coatings can last 10-20 years or even more. United Floor Coatings suggests professional-grade epoxy installations can last 20 years or more with normal residential use. This means you get a longer lifespan and reliable performance. This type of epoxy flooring is great for residential garages with light to moderate traffic. It also works well as a base coat for other floor coatings. Its longevity makes it a solid investment.

Understanding Polyurea Coatings

What is Polyurea Coating

Polyurea is a type of elastomer that forms a tough, flexible coating. You create polyurea coatings by mixing two main components:

Isocyanates: These are highly reactive chemicals.

Amines: These compounds, especially polyetheramines, react with isocyanates. This reaction forms strong urea linkages, giving you a robust polyurea.

Polyurea Pros and Cons

Polyurea offers significantly more durability than standard epoxy. You get up to five times greater strength. This makes polyurea an excellent choice for demanding environments. It provides high chemical resistance, protecting your floor from spills and harsh substances. You also benefit from its superior abrasion and impact resistance. However, traditional polyurea can be prone to UV damage. This means it might yellow or fade over time if not properly protected, which is a key difference in polyaspartic vs. polyurea.

Polyurea Cost & Durability

The cost for polyurea flooring can vary. You might find prices between $2 and $10 per square foot, depending on the specific product and installation. Despite the cost, polyurea offers enhanced durability. This makes it a worthwhile investment for your garage floor coatings. Its inherent strength provides excellent protection against daily wear and tear. This type of polyurea provides great value.

Polyurea Lifespan & Best Uses

Polyurea coatings generally offer a longer lifespan than epoxy. You can expect polyurea to last anywhere from 7 to 20 years or even more. A properly installed polyurea system can last 15+ years, with some expecting 40+ years with minimal maintenance. This longevity makes polyurea a strong contender for your garage flooring. It excels in areas needing superior chemical resistance and impact protection. For optimal performance and to prevent UV damage, you often see polyurea polyaspartic systems. This combination provides the best protection and durability. You gain a longer lifespan and better overall performance. Many professionals recommend a polyurea polyaspartic blend for top-tier results. Consider polyurea polyaspartic for your next project. This polyurea polyaspartic solution gives you peace of mind.

Polyaspartic Coatings: The Advanced Solution

What is Polyaspartic Coating

Polyaspartic is an advanced type of polyurea, representing a significant leap in floor coatings technology. You create polyaspartic polyurea by reacting a low-reactivity secondary-amine resin, known as polyaspartic resin, with an isocyanate curing agent. Specifically, you manufacture polyaspartic esters by reacting an amine with dialkyl maleate, often diethyl maleate. This process converts primary amines to secondary amines and introduces bulky groups that slow down the reaction. This unique chemistry gives polyaspartic coatings their exceptional properties. It also provides a superior mechanical bond with concrete compared to other polyurea coatings, forming a robust resinous flooring system.

Polyaspartic Pros and Cons

You will find polyaspartic coatings offer superior durability and a long-lasting aesthetic appeal. A key advantage of polyaspartic vs. polyurea is its excellent UV stability, meaning your floor won’t yellow or fade over time. This makes polyaspartic an ideal choice for high-performance resinous flooring. You also benefit from faster installation and curing times, which means less downtime for your garage. Polyaspartic provides outstanding protection, chemical resistance, and overall performance. While the initial cost might be higher than some polyurea or epoxy options, its longevity and enhanced durability often make it a more cost-effective solution in the long run.

Polyaspartic Cost & Durability

When considering polyaspartic coatings, you can expect costs to range from $4 to $9 per square foot, though some projects might see prices up to $12 per square foot depending on your garage size and floor condition. This investment brings you exceptional durability. Polyaspartic floor coatings are known for their resilience against impacts, abrasions, and chemicals, offering far greater protection than traditional polyurea coatings. You get a high-performance coating that stands up to daily wear and tear.

Polyaspartic Lifespan & Best Uses

You can expect a remarkable lifespan from polyaspartic floor coatings. These high-performance coatings typically last 15 to 20 years or even more, offering a longer lifespan than many other options. This extended longevity ensures a long-lasting finish for your garage. Polyaspartic is perfect for residential garages, commercial spaces, and any area needing a durable, attractive, and quick-to-install flooring solution. Its superior durability and excellent performance make it a top choice for anyone seeking maximum protection and a beautiful floor.

Polyaspartic vs. Polyurea vs. Epoxy: A Direct Comparison

You want the best for your garage floor, right? Let’s directly compare polyaspartic, polyurea, and epoxy to see how they stack up. This will help you understand why polyaspartic often comes out on top. You will see the key differences in their performance.

UV Stability and Yellowing Resistance

When you think about your garage floor, you probably don’t want it to change color over time. This is where UV stability becomes crucial. Powerful UV rays cause the chemicals in polyurea and epoxy floor coatings to break down quicker. This leads to a loss of glossy finish and discoloration, often yellowing. While some polyurea coatings include UV inhibitors, these only slightly delay the degradation. Floortex™ polyaspartic floor coating, however, offers top-notch UV protection. It holds its color and shiny finish much longer than any polyurea or epoxy coating and will never yellow.

The most significant advantage of polyaspartic vs. polyurea is its UV resistance. It won’t yellow, fade, or chalk over time. This makes polyaspartic the best option for outdoor spaces like patios, pool decks, or commercial floors with large windows that receive direct sunlight. You get lasting beauty with polyaspartic.

Coating | UV Resistance |

|---|---|

Polyaspartic | High—UV stable and won’t fade |

Epoxy | Low—Prone to yellowing and chalking |

Polyurea | Low—Will yellow over time without a topcoat |

This table clearly shows the difference in UV damage protection. You can see why polyaspartic is superior.

Chemical and Stain Resistance

Your garage floor faces many challenges, from oil spills to harsh cleaning agents. You need strong chemical resistance. Polyurea offers significantly more durability than standard epoxy, providing up to five times greater strength. This means polyurea can handle tough chemicals better than epoxy. Polyaspartic, as an advanced polyurea, takes this even further. It provides exceptional chemical resistance against a wide range of substances. You get superior protection against stains and spills with polyaspartic. This high level of chemical resistance ensures your floor looks great for years.

Impact and Abrasion Resistance

Think about tools dropping or cars driving in and out. Your garage floor needs to withstand a lot of abuse. Polyurea coatings are known for their impressive impact and abrasion resistance. They are much tougher than epoxy. This means fewer chips, scratches, and wear marks for you. Polyaspartic coatings, being an advanced form of polyurea, offer even greater durability. You get a surface that resists heavy impacts and constant friction. This superior durability makes polyaspartic an excellent choice for high-traffic areas.

Application Time and Curing Speed

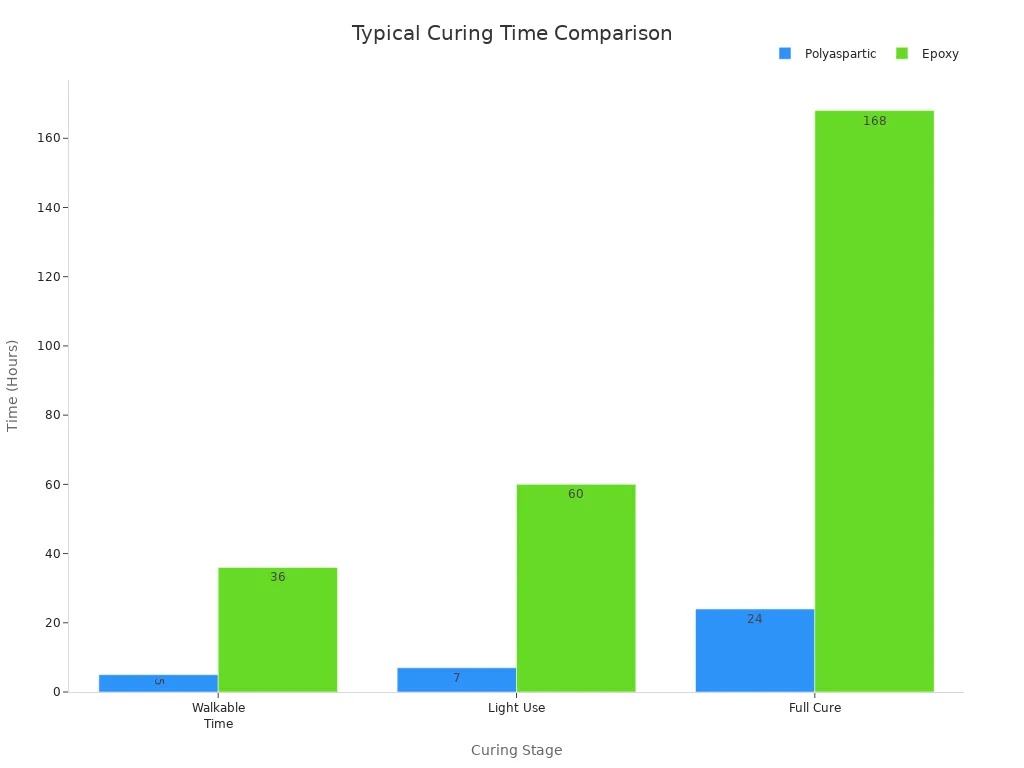

Nobody wants their garage out of commission for days. This is where application and curing times really matter. Polyaspartic coatings are known for their rapid curing, typically drying within 4-6 hours. This is significantly faster than epoxy coatings, which can take several days (usually two) to dry. Polyurea coatings also boast a quick dry time, around 6-8 hours, making polyaspartic even faster. You can walk on your polyaspartic floor much sooner.

Here’s a quick look at the curing times:

Feature | Polyaspartic | Epoxy |

|---|---|---|

Walkable Time | 4-6 hours | 24-48 hours |

Light Use | 6-8 hours | 48-72 hours |

Full Cure | 7+ days |

You can see the dramatic difference in how quickly you can use your garage again. Polyurea polyaspartic systems offer incredible speed.

Polyurea coatings cure quickly, becoming touchable within a few hours and fully cured in 24 hours. This is much faster than epoxy that takes a couple of days for full cure. Polyaspartic coatings take a little longer to cure than polyurea coatings, but still offer excellent speed. This quick turnaround is a huge benefit of polyaspartic vs. polyurea and epoxy.

Mechanical Bond and Adhesion

How well your coating sticks to the concrete is vital for its longevity. Epoxy is highlighted for its ‘Exceptional substrate adhesion‘. It is considered the ‘best polymer for bonding directly to concrete’. You get a very strong bond with epoxy. In contrast, polyurea was not originally engineered for bonding strength to concrete. It is more susceptible to ‘delamination or adhesion failures’ on concrete compared to industrial-strength epoxy.

However, Penntek’s Pure Polyurea demonstrates a pull-off strength of ‘1350 PSI‘. This often causes the concrete to fail before the polyurea. This significantly surpasses the industry benchmark for a good bond, which is ‘500 PSI’. While polyaspartic is a type of polyurea, it doesn’t bond as deeply with concrete as some other coatings. For the best performance, a polyurea polyaspartic system often uses an epoxy primer to ensure maximum adhesion. This combination gives you the best of both worlds: the strong bond of epoxy and the superior performance of polyurea polyaspartic. You get a robust flooring solution.

Choosing Your Garage Floor Coating in 2025

You’re ready to upgrade your garage floor, but how do you pick the right coating? It’s not just about what’s popular; it’s about what works best for your specific needs. Let’s break down the key factors you should consider when making your decision.

Budget and Investment Considerations

When you look at garage floor coatings, you might first think about the upfront price. However, you should really consider the long-term value. A cheaper option might seem appealing now, but it could cost you more in the future. For example, a cheap epoxy route might initially cost around $2,000. But if it peels or yellows by year four, you could face an additional $1,500 for removal and $2,500 for re-installation. That’s a total of $6,000 plus headaches over five years!

Feature/Scenario | Epoxy (Cheap Route) | Polyaspartic (Floortek Route) |

|---|---|---|

Initial Cost (Year 1) | $2,000 | $3,500 |

Longevity | Peels/yellows by Year 4 | Looks new at Year 20 |

Additional Costs (Years 1-5) | $1,500 (removal) + $2,500 (re-install) = $4,000 | $0 |

Total 5-Year Cost | $6,000 + headaches | $3,500 |

Total 20-Year Cost | N/A (would require multiple re-installations) | $3,500 |

Return on Investment | Higher short-term cost due to failures | Lower long-term cost, smarter investment |

As you can see, investing in a high-quality polyaspartic coating, even at $3,500 initially, offers much better long-term value. You get superior longevity and avoid costly repairs. This makes polyaspartic a smarter investment for your garage floor upgrade.

Garage Usage and Traffic Levels

How do you use your garage? This question is crucial for choosing the right floor coatings. If your garage sees heavy vehicle traffic, frequent spills, or acts as a workshop, you need a coating that can handle the abuse. Polyaspartic is often highlighted as the best concrete coating for high-traffic areas. It handles heavy wear, impacts, and scuffs with ease.

For garages with heavy vehicle traffic and frequent spills, you have several strong options:

Epoxy coatings offer outstanding protection against chemical spills and heavy vehicular traffic.

Polyurea coatings handle heavy impacts and even 24/7 truck movement.

Polyaspartic is excellent for all kinds of high-traffic areas, managing heavy wear and impacts.

Traffic coatings, including epoxy, MMA, and cementitious types, create a barrier against heavy and frequent vehicle loads. They also protect against substances like salt, oils, and other debris. This ensures your floor maintains its protection and performance.

Coating Type | Suitability for Heavy Traffic | Suitability for Frequent Spills (Chemical Resistance) |

|---|---|---|

Epoxy Coatings | Handles heavy loads: forklifts, trucks, constant foot traffic | Excellent chemical resistance (acids, solvents, oils) |

Polyurea Coatings | Handles heavy impacts, 24/7 truck movement | Handles extreme conditions, including chemicals |

Polyaspartic Coatings | Best for all kinds of high-traffic areas, handles heavy wear and impacts | Offers superior performance and durability |

Desired Aesthetic and Finish

Your garage floor doesn’t have to be boring! You can choose from many colors and finishes to match your style. Polyaspartic and epoxy systems offer a wide range of aesthetic options. Many companies let you choose vinyl flake combinations to add color and texture. These decorative flakes are a very popular way to enhance garage floor colors. They add visual interest and can even hide imperfections.

You can find popular options like:

Neutral tones: Soft grays and warm beiges offer versatility.

Metallic epoxy systems: These mix pigments to create stunning marble-like swirls or galaxy effects. Think silver and cobalt, copper and brass, or white with black highlights.

Decorative flakes: Examples include Shoreline, Gravel, Tidal Wave, and Domino.

Some providers offer over 140 color options for their epoxy and polyaspartic flooring. You can even find specific finishes like:

Classic Flake: For a consistent, seamless look.

Granite Flake: For a natural, granite-like feel.

Sandstone Flake: A stone-like option with a slight texture.

You can truly customize your garage floor to achieve the perfect look.

DIY vs. Professional Application

Are you thinking about installing your garage floor coating yourself? You might save some money upfront, but it’s important to weigh the pros and cons. DIY materials for a two-car garage typically cost around $1.50 per square foot, or approximately $600. In contrast, professional installation generally starts around $5.75 per square foot.

Category | Cost Range (per sq ft) | Two-Car Garage Cost |

|---|---|---|

DIY Epoxy Flooring | $3 – $12 | $720 – $1,800 |

Professional Installation (Total) | N/A | $4,000 – $5,500 |

While DIY seems cheaper, professional installers bring expertise and specialized equipment. They ensure proper surface preparation and application, which are critical for the longevity and performance of your floor. A poorly installed DIY job can lead to premature failure, costing you more in the long run. For polyaspartic and polyurea coatings, professional application is often recommended due to their fast curing times and specific application requirements. You want to ensure your investment lasts.

Climate and Environmental Factors

The weather conditions during application can significantly impact the success of your garage floor coating. You need to pay attention to temperature and humidity.

Epoxy: You should not apply epoxy if humidity is greater than 85 percent. Also, avoid application if the temperature is less than 5 degrees over the dew point. The most important temperature to check is your garage floor’s temperature, not just the air’s. Epoxy also requires a minimum temperature of 50-55°F (10-13°C).

Polyurea: For indoor application, substrate and ambient temperatures should be between 50°F and 90°F. Humidity levels for primer coats are typically 40-60% relative humidity. For outdoor polyurea application, temperatures must be above 50°F, and substrate temperatures must be at least 5°F above the dew point. You also need no rain for 24 hours after application.

Polyaspartic: This is where polyaspartic shines. Polyaspartic and polyurea can be applied in a broad range of temperatures, from -40°F to 40°F (-40°C to 4°C). This flexibility makes polyaspartic an excellent choice if you live in an area with extreme temperature fluctuations or need to apply the coating in less-than-ideal conditions. This wide application window contributes to its overall performance and ease of use for professionals.

You see, polyaspartic emerges as the top contender for most garage floor coatings in 2025. This polyaspartic offers unmatched durability, speed, and aesthetic retention. Polyaspartic provides superior protection and longevity. While polyaspartic excels, epoxy or polyurea still suit specific needs. An epoxy garage floor might be your choice. Consider traditional polyurea coatings. This polyurea offers good performance. You must weigh your needs and budget. Invest in the right floor coatings for a long-lasting finish. An epoxy coating can be great. This polyurea is also strong.

FAQ

Can I apply polyaspartic coating myself?

You can find DIY kits, but professional installation is often best. Polyaspartic cures very fast. This requires skill and speed for a flawless finish.

Does polyaspartic really not yellow over time?

Yes, polyaspartic offers excellent UV stability. It resists yellowing, fading, and chalking. Your floor will keep its original color and shine for years.

How soon can I drive on my new polyaspartic garage floor?

You can typically drive on your new polyaspartic floor within 24 hours. This quick cure time gets your garage back in action fast! 🏎️

See Also

Effortlessly Transform Your Garage Floor: Discover This Simple Densifier Solution

Australian Garage Floor Upgrade: One-Step Densifier for a Superior Finish

Beyond Peeling Paint: Durable Liquid Hardener for Your Garage Floor

Top Concrete Protective Sealers of 2025: Elevate Your Surfaces Now

Maximize Concrete Life: Essential 2025 Guide to Floor Hardener Application