Are you tired of your concrete roof leaking again? That frustrating “leaking concrete roof” problem costs you time and money. You can achieve a truly waterproof roof for 10 years or more. This guide shows you the best waterproofing products and the correct method for lasting waterproofing solutions. Move past temporary fixes to durable, high-performance waterproofing.

Key Takeaways

Understand why concrete roofs leak. Common issues include poor installation, flat angles, and clogged drains. For commercial buildings, pooling water and material degradation are main causes.

Choose the right waterproofing product for long-lasting protection. Options include liquid applied polyurethane membranes, polymer-modified cementitious coatings, reinforced bituminous membranes, EPDM rubber membranes, and acrylic elastomeric coatings.

Follow a precise, step-by-step application method. This includes thorough inspection, surface cleaning, crack repair, primer application, correct product application, and final inspection with regular maintenance.

Why Concrete Roofs Leak: Stopping “leaking concrete roof” Permanently

Common Causes of Concrete Roof Leaks

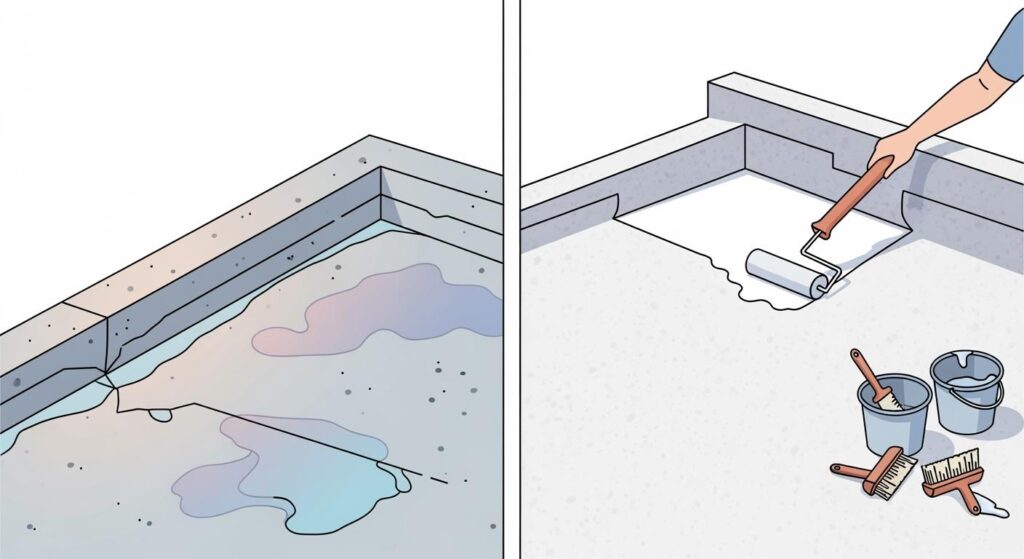

You’ve probably wondered why your concrete roof keeps leaking. That annoying “leaking concrete roof” problem often comes from several common issues. For homes, improper roof installation is a big culprit. This can leave gaps or cause tiles to slide easily. If your roof angle is too flat (less than 10-15 degrees), rainwater can sit there and seep in. Clogged gutters also stop water from flowing away, leading to stagnation and leaks. Strong, windy rain can push water into tiny holes and cracks. Sometimes, poor-quality roofing materials just can’t handle weather changes, and constant temperature swings make them crack over time. A flat concrete roof without a proper slope to a drain is a common issue. Even a shifted roof tile or a poorly waterproofed ridge or joint can cause problems.

For commercial buildings, especially those with flat roofs, pooling water is the main reason for leaks. It weakens materials and eventually gets through. Daily temperature shifts make materials expand and contract, causing joints to separate and sealants to crack. Materials degrade over time; joints pull apart, sealants crack, and waterproof membranes tear. Leaks often start near vents, drains, and skylights because of weak flashing or shifted seams. Blocked drains just make pooling water worse, leading to more leaks.

The Importance of Proper Surface Preparation

You can’t skip proper surface preparation if you want your waterproofing to last. Think of it like painting a wall; you wouldn’t paint over dirt. For your roof, you need a clean, smooth surface for the waterproofing material to bond correctly. This step ensures the new layer sticks well and creates a strong, continuous barrier, much like a perfectly laid rubber sheet. Without good preparation, even the best waterproofing product won’t perform as it should. It might peel, crack, or fail prematurely, leaving you with another “leaking concrete roof” situation. You want your roof to feel like a solid, protective rubber sheet.

Understanding Waterproofing System Lifespans

How long does waterproofing last? Generally, most waterproofing treatments give you 5 to 10 years of protection. The materials you choose and your roof’s current condition greatly affect this lifespan. For example, liquid membrane waterproofing goes onto concrete surfaces without joints, offering great water resistance. Cementitious waterproofing uses a thick, cement-based coating that hardens into a waterproof layer, often used with other systems. You want a system that acts like a durable rubber sheet, providing a long-lasting seal. Proper care and regular maintenance can extend the life of your waterproofing solution, making it perform like a resilient rubber sheet for even longer. Imagine your roof covered by a continuous, protective rubber sheet. This type of rubber-like barrier is key. You need a solution that feels like a thick rubber sheet, offering the elasticity of a strong rubber sheet. The best systems create a seamless, rubber-like barrier, like a giant, durable rubber sheet. This protective rubber layer is essential.

Top 5 Waterproofing Products: Best Types for 10-Year Durability

You want a roof that stays dry for a decade, right? Choosing the right product is key. Let’s look at the best types of waterproofing solutions that offer long-term protection. These high-quality waterproofing products can turn your leaky roof into a fortress.

High-Performance Liquid Applied Polyurethane Membranes

Imagine a seamless, flexible layer that covers your entire roof. That’s what you get with high-performance liquid applied polyurethane membranes. These are some of the best types of waterproofing available.

Benefits You’ll Love:

They offer excellent adhesion to your concrete.

This liquid membrane is highly flexible and durable. It acts like a tough, elastic rubber sheet.

You get strong resistance against UV rays and harsh chemicals.

Its high flexibility means it can bridge cracks, keeping your roof sealed.

This type of waterproofing is perfect for complex roof shapes.

Things to Consider for Application:

These membranes work great on flat roofs.

They are ideal for balconies and exposed terraces.

For areas with heavy foot traffic or equipment, like commercial or industrial roofs, polyurethane coatings are a top choice. They handle ponding water better than some other materials.

You will need UV-resistant topcoats for areas exposed to continuous sunlight. This ensures the polyurethane, which forms a shallow coat that cures into an elastic rubber sheet, lasts even longer.

Polyurethane coatings, like SOLIDFlex PULM, are solvent-based. They offer superior toughness and flexibility. They also have excellent impact resistance and adhesion to many surfaces. This makes them a fantastic option for durable waterproofing.

Advanced Polymer-Modified Cementitious Coatings

These coatings combine the strength of cement with the flexibility of polymers. They create a robust waterproofing layer.

Why They’re Great:

You can apply them to wet or damp surfaces. This saves you time.

They stick very well to your concrete.

Their flexible, elastomeric properties help bridge hairline cracks. This prevents water from getting in.

Some, like Deltaproof CB Flex, cure fast. You can walk on them sooner.

Products like BETEC™ Flex S150 are non-toxic. They also allow direct plaster or screed without affecting the bond.

SikaTop®-107 Plus is easy to use. It comes pre-packed and is impermeable. It resists abrasion and erosion well.

How to Apply Them Right:

First, make sure your concrete surface is clean and sound. Remove all dirt, oil, and grease.

You will mix two components (liquid and powder) until smooth. A slow-speed mixer works best.

Always apply at least two coats. The first coat goes on a damp, pre-wetted surface. Apply the second coat after the first one starts to set, usually within a few hours.

For products like SikaTop®-107 Plus, follow the specific mixing ratios carefully. You want to avoid drying or shrinkage cracks.

These coatings are among the best types of waterproofing for many situations. They create a strong, semi-flexible barrier, almost like a thin rubber sheet, protecting your roof.

Reinforced Bituminous Membranes

Think of a tough, rubber-like sheet that’s built to last. Reinforced bituminous membranes are exactly that. This bitumen waterproofing method is a reliable choice.

Key Benefits:

They are inherently waterproof materials.

These membranes are flexible. They move with your concrete and handle minor settling. This gives you great crack bridging capabilities.

They have a tough, rubber-like composition.

Some, like BITUTHENE® CP, are chemically resistant.

You get unparalleled water protection from a robust film and special adhesive.

Installation Considerations:

You can apply them cold, even in cooler temperatures. This means no fire risk during installation.

They are easy to apply as sheets on various concrete surfaces.

Features like RIPCORD® make positioning easy.

Self-adhesive overlaps eliminate leaky seams. You don’t need special equipment.

You can even apply them to damp or green concrete with a primer. This saves time on projects.

The controlled thickness ensures consistent application.

Reinforced bituminous membranes offer a long service life, often exceeding 20 years. They are excellent for various roofing applications, especially in high-rainfall areas. Their composition, often asphalt reinforced with polyester or fiberglass, gives them enhanced strength and flexibility. This membrane waterproofing creates a durable rubber sheet barrier.

EPDM Rubber Membranes

EPDM (ethylene-propylene-diene monomer) is a synthetic rubber. It’s a fantastic choice for waterproofing your concrete roof. These are some of the best types of waterproofing for durability.

Advantages You’ll Appreciate:

They are cost-effective and easy to install.

EPDM membranes are highly durable.

They resist UV rays and weather damage very well.

You will find they require minimal maintenance.

They have a long lifespan and are energy-efficient.

EPDM is lightweight and extremely flexible. It can even withstand expanding buildings.

Ideal Scenarios:

You often see EPDM used in large commercial buildings, hospitals, and schools.

It’s perfect for encapsulating expansion joints in floors, walls, and roofs. For example, AquAtec uses a specialized EPDM membrane for this purpose. This rubber sheet is draped into the expansion gap and bonded to the substrate.

EPDM products are UV-resistant. This means they won’t degrade or discolor from long sun exposure. This makes them crucial for external applications like concrete roof waterproofing.

This type of rubber membrane creates a resilient, long-lasting rubber sheet over your roof.

Acrylic Elastomeric Coatings

Acrylic elastomeric coatings are a popular choice for concrete roof waterproofing. They offer a blend of performance and practicality.

Benefits for Your Roof:

They prevent leaks by sealing seams, cracks, and joints.

These coatings can add 10–20 years to your roof’s lifespan.

Their reflective properties reduce heat absorption. This lowers your cooling costs.

They offer cost-effective maintenance, much cheaper than full roof replacement.

They are environmentally friendly.

You can improve your building’s look by covering stains and uneven weathering.

Application Guidelines:

Start with a thorough roof inspection. Find all leaks and damaged areas.

Clean the surface well. Power wash to remove dirt and loose material. Repair any damaged sections.

Apply a primer if the coating manufacturer requires it. This improves adhesion.

Spray or roll on one or more layers. Follow the manufacturer’s instructions for thickness.

Allow several days for full curing. It might dry to the touch in hours, but full curing takes longer.

Inspect for even coverage. Plan periodic inspections every 2–3 years.

Common Mistakes to Avoid:

Never apply coating over dirt or damaged surfaces. This reduces effectiveness.

Choose the right coating. Acrylics are not ideal for roofs with frequent standing water.

Don’t apply too thin or too thick a layer.

Leave it to professionals if you lack experience. This ensures proper application and warranty protection.

Acrylic elastomeric coatings typically last 5–10 years. You can extend this with routine maintenance. They are best for roofs in hot, dry climates due to their reflectivity and UV protection. They are affordable and easy to apply. However, they need dry conditions for application and are not recommended for areas with ponding water. These coatings form a protective, flexible rubber sheet-like layer.

The Correct Method: 10-Year Waterproof Seal Application

You want your concrete roof to stay dry for a decade, right? Achieving a 10-year waterproof seal isn’t just about picking a great product. It’s also about following a precise, step-by-step application method. This process ensures your chosen waterproofing solution performs at its best, creating a durable, protective layer, much like a giant, resilient rubber sheet.

Step 1: Thorough Roof Inspection and Leak Identification

Before you do anything else, you need to know exactly where your leaks are coming from. You should conduct a thorough roof inspection. First, you need to check the roof and attic. This helps you locate the source of any leak and assess how bad it is. You can trace the leak’s path using special tools. Moisture meters and thermal tools are very helpful. You also need to do a physical inspection. Look for cracks, damaged flashing, or areas where water might pool. This initial step is crucial for effective waterproofing.

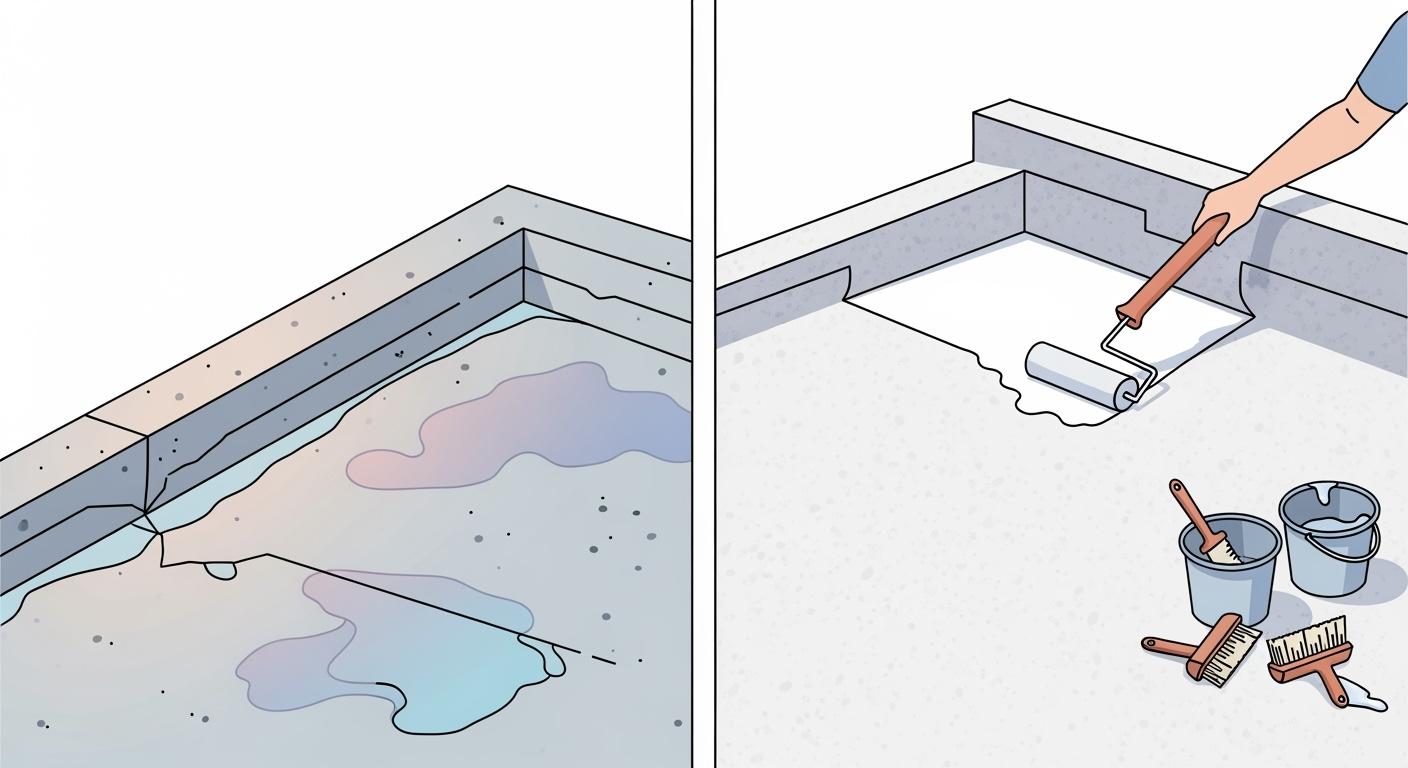

Step 2: Essential Surface Cleaning and Preparation

Proper surface preparation is non-negotiable for long-lasting waterproofing. Think of it as laying the groundwork for your protective rubber sheet. You must ensure surfaces are clean. They need to be free from dirt, rust, grease, oil, mould, or any other loose material. For mouldy areas, you should wire brush them. Then, clean them with soap and water. Brush them again to remove any remaining dirt.

Your surfaces must be sound, smooth, and free from dust, laitance, loose matter, oil, or other contaminants. You need to remove dust, dirt, concrete and construction waste, leaves, or other foreign materials. You can do this by vacuuming or broom cleaning. Repeat this as necessary to keep the surface clean.

Sometimes, you need to strengthen the concrete itself. Products like BANDě Crystal Floor Hardener can improve the substrate’s integrity. Integral waterproofing solutions, such as Estomax CWP or Estop Admix WP2000, can also enhance the concrete’s resistance to water from within. This creates a stronger base for your external waterproofing.

Step 3: Repairing Cracks and Damaged Areas

Even small cracks can become big problems. You must repair all cracks and damaged areas before applying any waterproofing. Use high-quality waterproofing sealants or epoxy resins for effective crack repair. These materials fill the gaps and create a smooth, continuous surface. This step is vital for preventing future water intrusion. It helps ensure your final waterproofing layer acts like a seamless rubber sheet, completely sealing off your roof.

Step 4: Primer Application (If Required)

Some waterproofing products need a primer. Always check the manufacturer’s instructions. A primer creates a strong bond between your concrete surface and the waterproofing material. It helps the waterproofing adhere better and last longer. For example, bonding products like HACK AID PLAST can improve primer adhesion. This ensures your protective rubber layer sticks firmly to the roof.

Step 5: Correct Application of Chosen Waterproofing Product

Now comes the main event: applying your chosen waterproofing product. This is where precision matters most. Always follow the manufacturer’s specific instructions for your product. For instance, if you use a dry powder like Deltacrys Super, the application varies. For brush-applied slurry, you might use 1 kg per square meter for a single coat, mixed 5 parts powder to 2 parts water. For a first coat, you might use 0.8 kg per square meter, mixed 5 parts powder to 3 parts water.

If you spray it, follow the brush application mix proportions. Immediately follow with a brush to ensure penetration. For a dry shake application, you apply the powder evenly at 1 kg per square meter. Then, you must power trowel it for finishing; this is essential for success. Whether you use liquid membranes, cementitious coatings, or EPDM rubber sheets, proper technique ensures a uniform, durable, and waterproof barrier. You want to create a continuous, protective rubber sheet over your entire roof.

Step 6: Final Inspection and Maintenance Tips

After application, you need to perform a final inspection. Check for any missed spots, thin areas, or imperfections. Address these immediately. To ensure your waterproofing lasts for 10 years, regular maintenance is key. Periodically inspect your roof for debris, new cracks, or signs of wear. Clean gutters and drains to prevent water pooling. A little proactive care goes a long way in maintaining your roof’s protective rubber sheet.

Factors for a 10-Year Waterproofing Lifespan

You want your concrete roof to stay dry for a decade. Several key factors influence how long your waterproofing will truly last. You need to consider these points for long-term success.

Climate and UV Exposure

You know that weather plays a big role in how long your roof lasts. Intense sunlight, high humidity, and volatile weather conditions can really challenge your roof’s waterproofing. UV rays are especially tough. They can cause finishes to fade, crack, or blister. You need materials with UV protection to maintain color and integrity. For example, Duolong resin roof tiles are made for regions with intense sun. They have a UV-resistant ASA surface layer. This protects against degradation, discoloration, and brittleness. This kind of protection addresses issues that affect other roofing materials within a few years. You want your waterproofing to act like a durable rubber sheet, resisting the sun’s harsh effects. A good rubber sheet won’t break down easily.

Quality of Installation

The quality of installation is super important. You can have the best waterproofing product, but if it’s not applied correctly, it won’t last. When a qualified contractor applies a waterproofing membrane correctly, it can last 10–15 years or even longer. Its longevity depends on the membrane type, surface condition, and weather exposure. Professional concrete waterproofing shields concrete for years. Our solutions hold strong over time, giving your roof long-lasting protection. This early protection prevents severe damage. It helps you avoid costly repairs and future maintenance. You need a perfectly installed rubber sheet, not a poorly fitted one. A well-installed rubber sheet creates a seamless barrier. This ensures your roof acts like a continuous rubber sheet, protecting your home.

Regular Maintenance and Inspections

You also need to keep an eye on your roof. Regular inspection and maintenance help extend the protection even further. You should check for debris, new cracks, or any signs of wear. This proactive approach helps your waterproofing last. Think of it as maintaining that protective rubber sheet. You want to ensure the rubber sheet remains intact.

Substrate Movement and Structural Integrity

Your concrete roof isn’t completely static. It can move slightly due to temperature changes or structural shifts. This movement can stress your waterproofing. You need a flexible waterproofing system that can handle this. A good rubber sheet-like membrane will stretch and contract without tearing. This flexibility is crucial for long-term durability. If your substrate moves too much, even the best rubber sheet can fail. You need a robust rubber sheet that adapts.

A 10-year waterproof concrete roof is achievable. It’s not just a dream. This waterproofing needs the right rubber product. Prepare the rubber surface well. This creates a strong rubber sheet. Invest in quality rubber waterproofing. Get professional rubber installation. Enjoy a leak-free rubber property. No more “leaking concrete roof”. Your rubber roof will be a perfect rubber sheet. It’s like a protective rubber sheet. This rubber sheet will last. It’s a resilient rubber sheet, a true rubber sheet. This rubber sheet is your shield. This rubber sheet is your ultimate rubber sheet protection.

FAQ

How often should I check my waterproofed concrete roof?

You should inspect your roof at least once a year. Look for any damage to your protective rubber sheet. This helps maintain your roof’s durable rubber layer. Think of it as checking your strong rubber sheet. You want that rubber sheet to stay perfect.

Can I apply waterproofing myself, or do I need a professional?

For a 10-year seal, professional application is best. They ensure your rubber sheet is perfectly installed. This creates a flawless rubber barrier. A professional makes sure your rubber sheet is a true rubber sheet.

What if my roof already has an old waterproofing layer?

You usually need to remove old, failing layers. This ensures the new rubber sheet bonds well. A clean surface helps your new rubber protection last. You want a fresh rubber sheet. This new rubber sheet will be your best rubber sheet.

See Also

Top 10 Concrete Sealers: Ultimate Protection for Your Surfaces

Canadian Winters: Choosing the Optimal Concrete Sealer for Harsh Conditions

Rigid Waterproofing Sealers: Essential Home Protection Explained and Demonstrated

Cement Crack Sealer Mastery: Your Ultimate Guide to Durable Repairs

Understanding Rigid Waterproofing Sealers: Their Function and Application Explained