Ever wonder how to make your surfaces last longer? A penetrating sealer is a liquid treatment that soaks into materials like concrete, not just sitting on top. It protects your surfaces from water, stains, and general wear. Understanding this type of penetrating sealer is key for durable protection in your home or property.

Key Takeaways

A penetrating sealer soaks into surfaces like concrete. It protects them from water and stains without changing their look.

These sealers work inside the material. They make surfaces stronger and easier to clean.

Different types of penetrating sealers exist. Choose the right one for your surface to get the best protection.

What is a Penetrating Sealer?

Have you ever wondered what makes a surface truly resilient? It often comes down to what’s inside it, not just what’s on top. That’s where a penetrating sealer comes in.

Defining Penetrating Sealers

A penetrating sealer is a special liquid treatment. It doesn’t just sit on the surface; it actually dives deep. Think of it like a sponge soaking up water. This liquid treatment enters the tiny, microscopic pores of materials like concrete, natural stone, and even brick. It works its magic underneath the surface, giving you invisible protection. You won’t see a film or a coating, just the natural beauty of your material, but now it’s much stronger.

Different types of penetrating sealers use various chemical compositions to achieve this deep dive. For example, you’ll find sealers based on silane or siloxane molecules.

Sealer Type | Chemical Composition |

|---|---|

Silane | Based on silane molecules, which are smaller in size. |

Siloxane | Based on larger siloxane molecules. |

You also have siliconate and silicate types, which are derivatives of the silane family.

Sealer Type | Chemical Composition |

|---|---|

Siloxane | A derivative of the Silane family, often containing a mixture of different sized particles, including a small molecular structure Silane component and a larger molecular structure Siloxane component. |

Siliconate | A derivative of the Silane family, possessing a medium-sized molecular structure. |

Silicate | Four main types: Sodium, Potassium, Lithium, and Colloidal Silica. |

The size of these molecules really matters for how deep the sealer can go. Smaller molecules can penetrate further, offering protection from within.

Sealer Type | Particle Size | Penetration Capability |

|---|---|---|

Silane | Smallest particle size | Deep penetration |

Siloxane | Largest particle size | Prohibits deep penetration |

Silicate | Small particle size | Good penetration |

Siliconates | Medium-sized particles | Forms internal cross-linked membrane |

Silicone | Shallow penetrators | Excellent water and oil resistance, but shallow penetration |

Hybrids | Combinations of penetrating sealers and/or other resins | Specific type of protection or substrate enhancement |

Consider these molecular sizes:

Sealer Type | Particle Size | Penetration Capability |

|---|---|---|

Silanes | Very small molecular structure | Deep penetration |

Siloxanes | Larger molecular structure (often a mixture with small Silane components) | Good balance between penetration and coverage |

Siliconates | Medium-sized molecular structure | Moderate penetration |

Colloidal Silicas | 5-8 nanometers up to about 50 nanometers | Greater penetration |

Silicates | Smaller sized molecules | Good penetration |

This deep penetration is key to how a penetrating sealer protects your surfaces.

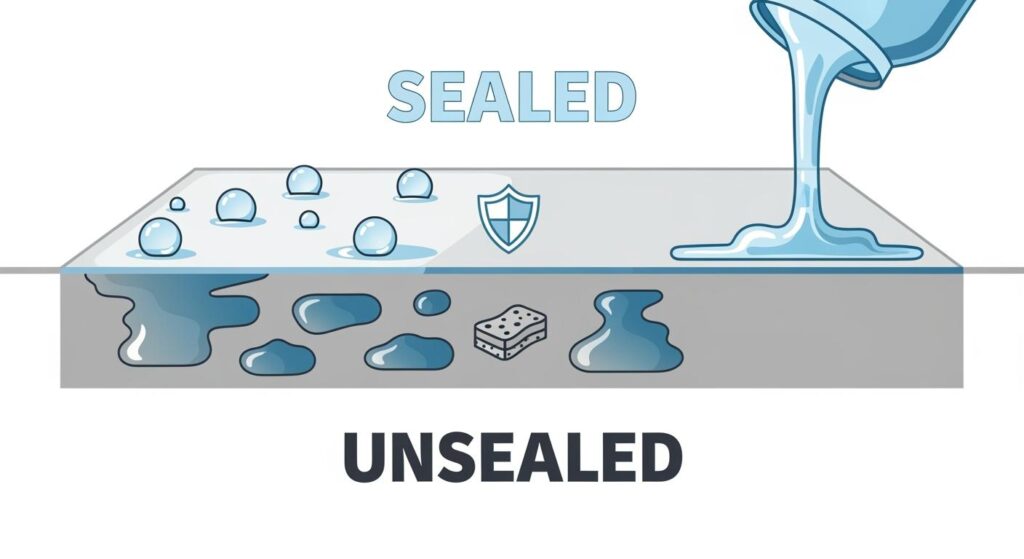

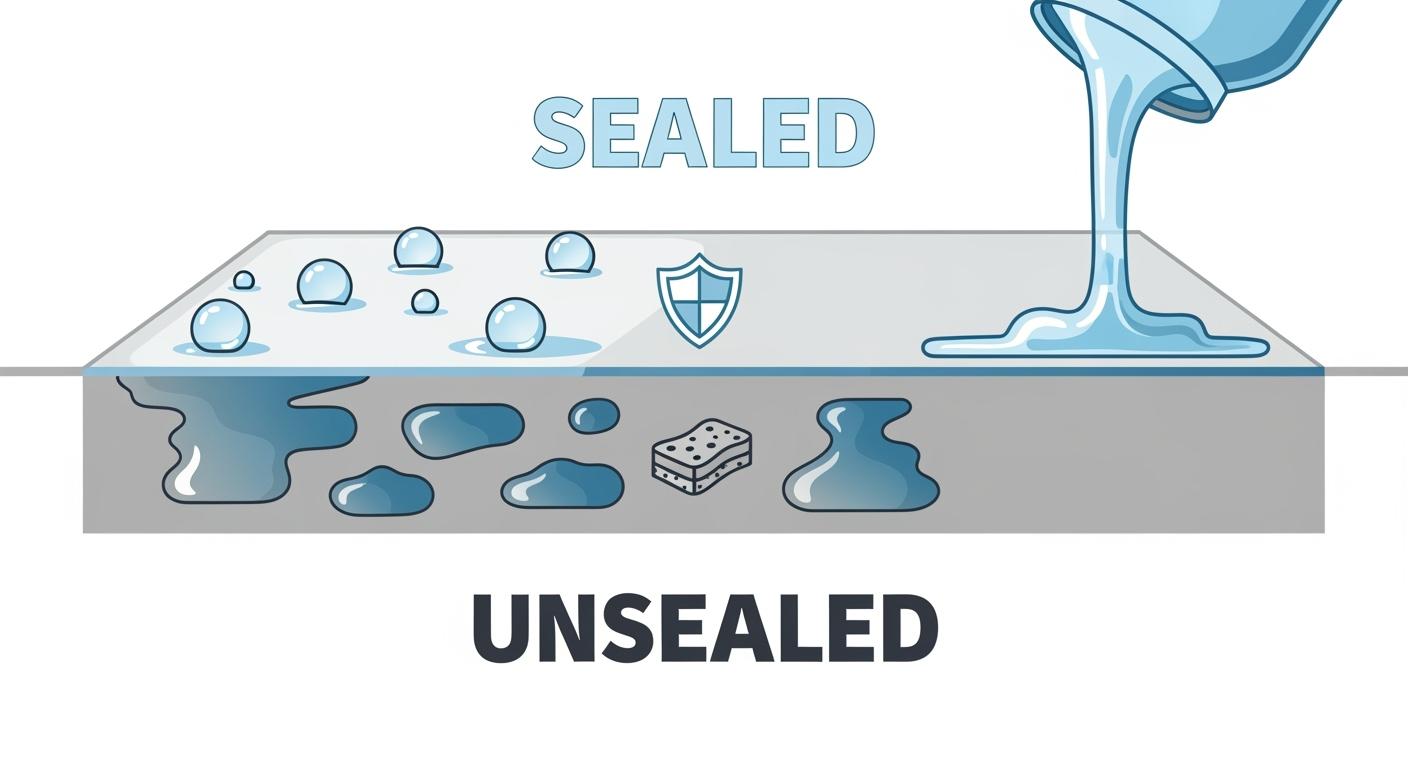

Penetrating vs. Topical Sealers

You might wonder, “Isn’t any sealer the same?” Not at all! There’s a big difference between a penetrating sealer and a topical sealer.

A topical sealer creates a film or coating on top of your surface. Think of it like painting a clear coat over wood. It can give a glossy finish and might change the look of your material. While it offers protection, this surface layer can wear down, scratch, or even peel over time, especially with heavy foot traffic or exposure to the elements. It also traps moisture, which can lead to problems like efflorescence (those white powdery deposits) or mold growth underneath the film.

On the other hand, a penetrating sealer works within the material. It doesn’t form a visible layer. This means your surface keeps its natural look and feel. Because it’s inside the pores, it won’t peel, flake, or wear away from the surface. It allows the material to “breathe,” letting moisture vapor escape. This breathability is super important for preventing moisture-related damage. When you choose a penetrating concrete sealer, you’re investing in protection that becomes part of the material itself, offering long-lasting, invisible defense.

How Penetrating Sealers Work

Mechanism of Action

You know a penetrating sealer works from within. But how does it actually do that? These sealers are not just sitting on top; they absorb deep into the microscopic pores of your concrete or other porous materials. Once inside, they don’t just fill space. They chemically bond with the material. This creates a new, protective layer that’s integrated into the surface itself.

Different types of penetrating sealers achieve this bond through various chemical processes. Take a look at how some common types work:

Sealer Type | Chemical Process |

|---|---|

Silicate | Reacts with alkalis and calcium hydroxide to form crystalline structures that plug capillaries. |

Silane, Siloxane, Siliconate | Penetrates and forms cross-linked silicone resinous membranes within the surface. |

Fluorinated | Chemically reacts with the substrate to form strong Carbon-Fluorine bonds. |

General Penetrating Sealers | Penetrate into capillaries, chemically react with the surface, and create a new chemical solid that acts as a breathable barrier. |

This chemical reaction is key. It means the protection isn’t just a temporary coating. It becomes a permanent part of your surface.

Water and Stain Repellency

Once bonded, penetrating sealers create an invisible barrier. This barrier blocks the pores from absorbing unwanted substances. Think about water, oils, or chemicals. They can’t get in! Instead, the penetrating sealer increases the surface tension of the material. What does this mean for you? When water hits the treated surface, it won’t soak in. It will bead up and roll right off. This is the magic of water repellent sealers at work. You’ll see droplets forming, almost like tiny pearls. This dramatically reduces water penetration and keeps your surfaces dry. It also prevents stains from setting in. Spills become much easier to clean up. You won’t have to worry about deep-seated stains or damage from everyday liquids. This protection is crucial for preventing long-term moisture damage.

Surface Strengthening and Densification

Beyond repelling liquids, some penetrating sealers actually make your surfaces stronger. Silicate and siliconate sealers, for example, are fantastic at this. They chemically react with free lime (calcium) and alkalis already in your concrete. This interaction forms Calcium Silicate Hydrate (CSH). CSH is a natural mineral. It’s the same stuff that gives concrete its strength when you mix water with Portland Cement. By filling the capillaries and reducing porosity, CSH makes your concrete harder and more durable. This process is called densification. It’s like giving your concrete an internal skeleton.

This added strength is vital for protecting your concrete. It helps against many types of damage. You get better resistance to UV rays, which can fade and degrade surfaces over time. It also fights against mold growth, which thrives in damp, porous environments. And during cold weather, this penetrating concrete sealer protects against freeze-thaw damage. This happens when water seeps into pores, freezes, expands, and then thaws, causing cracks. By preventing moisture from entering, you stop this cycle.

Types of Penetrating Sealers

When you choose a penetrating sealer, you find different types, each with unique strengths. Understanding these various types of penetrating sealers helps you pick the best one for your project.

Silane and Siloxane Sealers

These are very popular types of penetrating sealers. Silane-siloxane sealers excel at repelling water. They protect your surfaces from environmental damage like rain and frost. You often see silane-siloxane sealers used on concrete driveways and patios because they offer excellent, long-lasting water protection without changing the look of the surface.

Silicate and Siliconate Sealers

Do you want to make your concrete stronger? Silicate and siliconate sealers are perfect for densifying and hardening surfaces. They react with the concrete to improve its strength and durability. For example, a high-quality product like BANDě Densifier uses this technology to make your concrete more resistant to wear and tear.

Fluorinated Penetrating Sealers

For advanced stain protection, especially against oil-based spills, you should consider fluorinated penetrating sealers. These sealers are fantastic at repelling tough stains. They often use C-6 fluoropolymers and fluorocarbons to create a strong barrier. This makes cleaning up oil, grease, and other stubborn liquids much easier for you.

Hybrid Sealer Formulations

Sometimes, you need a sealer that does a bit of everything. Hybrid sealer formulations combine the benefits of different technologies for broader protection. For instance, some hybrids blend silanes and siloxanes. You can find silane-siloxane sealers in active concentrations from 5% up to 100%. Products like Helix Repel are great examples; they are solvent-based silane and siloxane hybrid silicone water repellents. You can also find water-based silane and siloxane hybrid options, giving you flexibility for various applications.

When and Where to Use Them

Knowing when and where to apply a penetrating sealer is just as important as understanding what it is. You want to make sure you’re using the right product for the right job to get the best protection.

Ideal Surfaces for Protection

You can use penetrating sealers on many porous surfaces. They work great on concrete, natural stone (like granite, marble, and limestone), brick, grout, and even stucco. For example, fluorinated sealers work best on dense surfaces. Think machine-troweled concrete, cement terrazzo, or even mortar. Silane sealers are perfect for extremely dense concrete, such as pre-cast concrete or high-performance concrete found in parking garages and bridge decks. You should generally avoid using silane sealers on very porous surfaces.

Common Applications

You’ll find penetrating sealers protecting surfaces in many places. They are excellent for concrete driveways, patios, and walkways, keeping them safe from water and stains. You can also use them in basements and garages to prevent moisture damage and make cleaning easier. Inside your home, they protect natural stone countertops, tile grout, and shower walls. For instance, you can apply silicate sealers to new concrete, but you often need to dampen the surface first to help them penetrate. After applying, remember to rinse thoroughly to prevent white residue.

Key Considerations for Selection

When you choose a sealer, think about the specific needs of your surface. Consider the application rate; for standard curing-and-sealing compounds with 25% solids or more, you can expect 300–600 square feet per gallon. Less than 25% solids might cover 200–600 square feet per gallon. Always test a small area first to find the actual coverage rate.

You also need to think about safety and environmental impact. Solvent-based sealers might contain VOCs and be flammable, so you must use them with good ventilation and keep them away from heat. Water-based sealers are generally safer, user-friendly, and have low or zero VOCs. Always wear eye protection and gloves, no matter the sealer type. For protecting your concrete, especially in commercial settings, specialized training is often required. Professionals understand product chemistry, equipment, and safety protocols, ensuring proper application and preventing workplace hazards.

Aspect | Solvent-Based Sealers | Water-Based Sealers |

|---|---|---|

Hazardous Nature | May be hazardous, contain VOCs, flammable. | Not considered dangerous, user-friendly, zero/low VOCs. |

Safety Precautions | Keep away from heat, use ventilation, eye protection, gloves. | Use ventilation, eye protection, gloves. |

Environmental Impact | Do not contain solvents, zero or very low VOCs. | Do not contain solvents, zero or very low VOCs. |

Key Benefits of Penetrating Sealers

You invest in your property, and you want that investment to last. Penetrating sealers offer several key advantages that help you protect your surfaces effectively and efficiently.

Long-Lasting Surface Protection

You get protection that truly endures. Penetrating sealers generally have longer life expectancies than topical sealers. They become part of the surface, wearing away only as the surface itself wears. For example, water repellent penetrating sealers can last up to 5-7 years or more. Densifiers and hardeners can even last 10 years or more, even when exposed to outdoor conditions. Silane-siloxane sealers, a type of penetrating sealer, are known for their exceptional longevity. Some formulations last up to 10 years. They are ideal for exterior applications frequently exposed to the elements. They form a protective barrier that endures harsh environmental conditions. This prevents moisture-related damage like freeze-thaw cycles and cracking.

Preserving Natural Appearance

You want your surfaces to look their best, and penetrating sealers help you achieve that. They work beneath the surface, so they do not alter its appearance. Your concrete, stone, or grout keeps its natural look and texture. For instance, Lithi-Tek 9500 results in a treated surface that is slip-resistant and does not change its appearance. Concrete Sealer N also offers positive slip resistance. SlipDoctors Polish Grip is a professional-grade penetrating sealer designed to provide anti-slip protection on various surfaces. It forms an invisible barrier that increases traction and improves resistance to spills and stains. This offers effective anti-slip protection while maintaining the surface’s natural shine.

Simplified Maintenance

You will find cleaning much easier with a sealed surface. Penetrating sealers create a barrier that repels water and stains. Spills bead up on the surface, making them simple to wipe away. You spend less time scrubbing and less money on harsh cleaning chemicals. This makes routine maintenance a breeze for you.

You now understand a penetrating sealer works from within, offering deep protection for your surfaces. Different types, like silane or silicate, provide unique benefits, so choose wisely for your specific needs. Investing in a high-quality penetrating sealer truly preserves your property’s value and beauty for years.

FAQ

How often should you reapply a penetrating sealer?

You typically reapply every 5-10 years. This depends on the sealer type and how much traffic your surface gets. Always follow the manufacturer’s guidelines for the best protection.

Will a penetrating sealer change your surface’s appearance?

No, it won’t. Penetrating sealers work inside the material. They keep your surface’s natural look and texture completely unchanged.

Can you use penetrating sealers on any surface?

You use them on porous materials like concrete, stone, and grout. They are not for non-porous surfaces. Always check the product’s specific recommendations before applying.

See Also

Rigid Waterproofing Sealer: Essential Home Protection Explained for Durability

Understanding Rigid Waterproofing Sealers: Their Function and Application

BANDě Concrete Sealers: Film-Forming or Penetrating for Australian Environments

Industrial Floor Protection: The Ultimate Guide to Concrete Sealers

Elevate Your Surfaces: Top Concrete Protective Sealers for 2025