Concrete floor hardeners, also called concrete densifiers, are chemical-based liquid substances. They enhance the durability and performance of concrete surfaces. These solutions penetrate the concrete. A densifier strengthens the concrete, making it more resistant to wear, abrasion, and chemical attack. Understanding this densifier and its function is key for effective concrete floors maintenance and longevity.

Key Takeaways

Concrete floor hardeners make concrete stronger. They protect it from wear and damage. This helps floors last longer.

Hardeners work by filling small holes in the concrete. This makes the surface harder and more resistant to dust and chemicals.

You can use liquid hardeners on old concrete. You can also use dry shake hardeners on new concrete. Both types make floors much more durable.

What is a Concrete Floor Hardener and How It Works

Defining Concrete Floor Hardeners

A concrete floor hardener is a special liquid solution. People apply it to concrete surfaces. Its main job is to make the concrete stronger and more durable. Think of it as a super-booster for your concrete. These hardeners, often called concrete densifiers, are typically liquid solutions. They penetrate the concrete surface.

What are they made of? Liquid hardeners primarily consist of silicate compounds. These can be sodium silicate, potassium silicate, or lithium silicate. Each type of silicate densifier offers slightly different properties. However, not all hardeners are liquid. Some are dry shake hardeners. These are powders people spread onto fresh concrete. Dry shake hardeners contain hard-wearing aggregates, cement, and various additives like color pigments or microfibers. These dry shake hardeners create a very tough surface. Many industrial settings prefer dry shake hardeners for their extreme durability. Even decorative concrete flooring can benefit from certain dry shake hardeners. Both liquid and dry shake hardeners aim to improve the concrete’s surface.

The Chemical Process of Concrete Densification

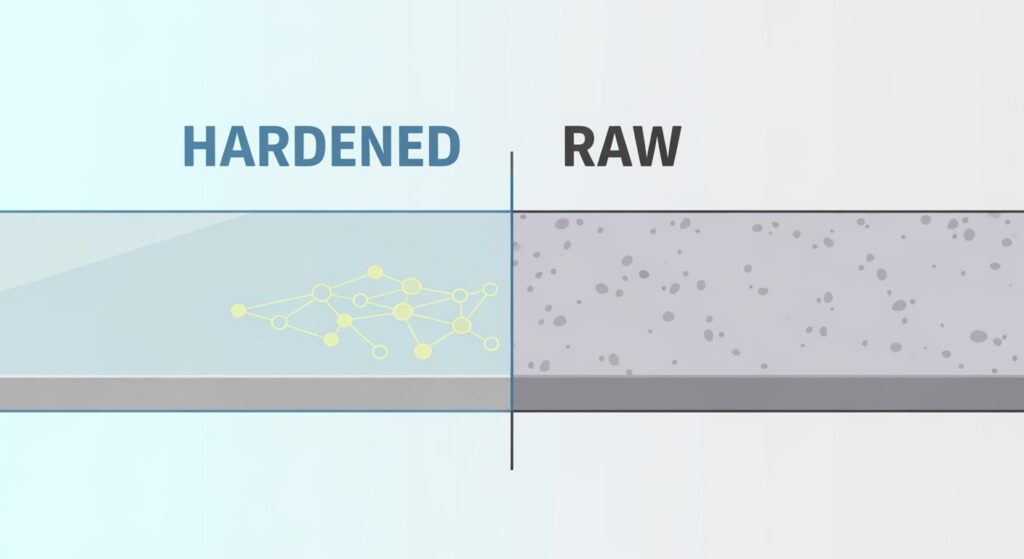

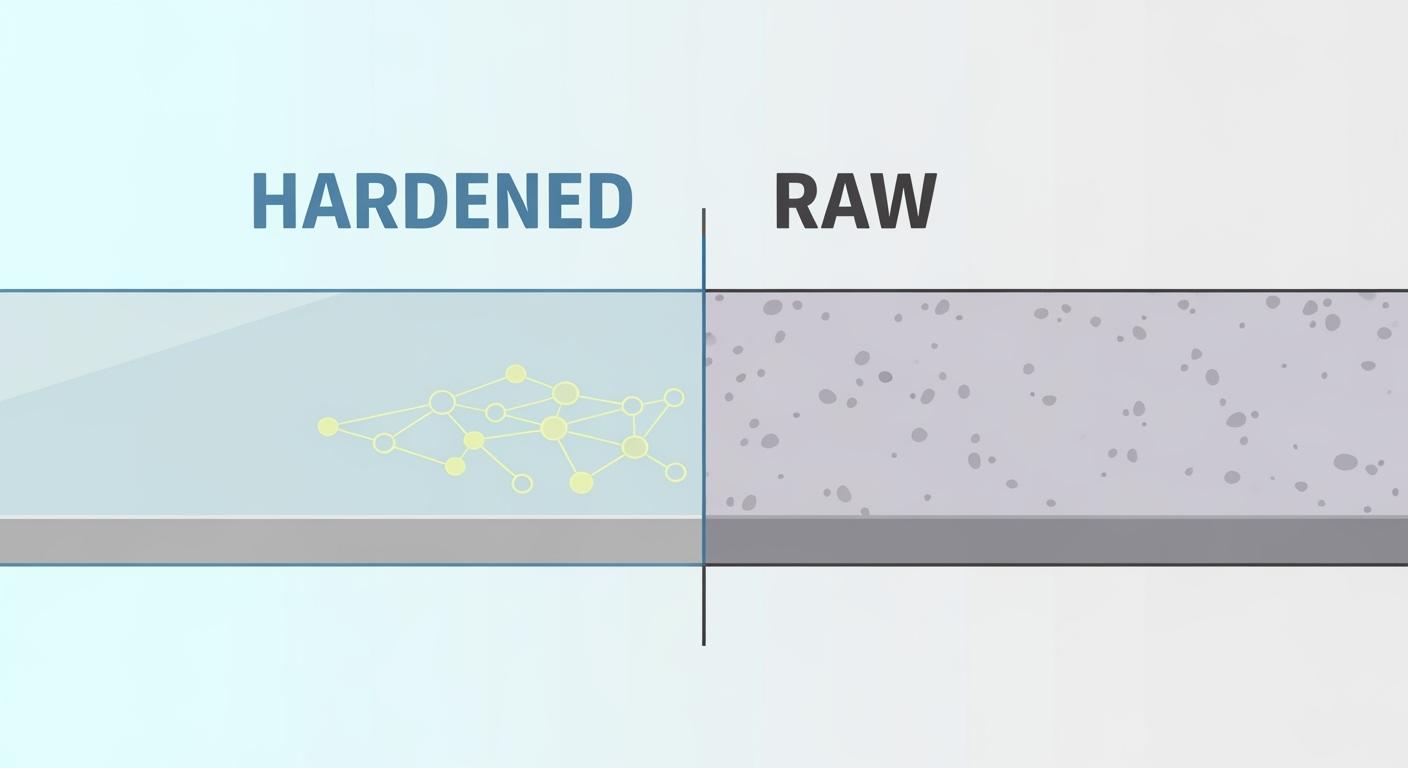

Now, how does a densifier actually work its magic? It is a fascinating chemical process. When you apply a liquid densifier to concrete, it does not just sit on top. The liquid solution penetrates deep into the concrete’s pores. Once inside, the densifier starts a chemical reaction.

Concrete naturally contains calcium hydroxide. This is an inert byproduct from when the concrete first hardened. It is also known as hydrated lime. This calcium hydroxide is a weaker, more porous material within the concrete. The silicate in the densifier chemically reacts with this calcium hydroxide. This reaction transforms the calcium hydroxide into Calcium Silicate Hydrate (CSH). CSH is the same compound that gives concrete its original strength and hardness. It is essentially the “glue” that holds concrete together.

This newly formed CSH gel fills the microscopic pores and voids within the concrete. As it dries and hardens, it creates a much denser and stronger surface. This process of concrete densification significantly increases the concrete’s durability. A proper concrete densification treatment makes the concrete more resistant to damage. A silicate densifier essentially makes the concrete stronger from within. This densifier also helps protect the concrete from moisture.

Why Concrete Floors Need Hardening

Why bother with a concrete floor hardener in the first place? Untreated concrete floors face several common problems. Over time, they can suffer from surface wear and abrasion. This is especially true in high-traffic or heavy-use areas. Think about busy warehouses or retail spaces. The constant movement takes a toll on concrete flooring.

Another common issue is dusting. This happens when the top surface of the concrete wears away or weathers. It releases fine dust particles. This dust can be a nuisance and even a health concern for any concrete flooring. Ultimately, these issues lead to deterioration. This affects the long-term durability and wearability of the floor.

Applying a densifier helps combat these problems. It makes the concrete surface much harder and more resistant. This increased hardness directly translates to better abrasion resistance. For example, some concrete admixtures can more than double the concrete’s wear life. This significantly enhances abrasion resistance. Hardened concrete flooring stands up better to daily abuse. It reduces dusting and extends the life of your concrete. This makes a densifier a smart choice for any concrete floor. Many commercial concrete flooring projects benefit greatly from a densifier. This powerful densifier ensures long-term performance.

Types, Application, and Benefits for Concrete Floors

Liquid vs. Dry Shake Hardeners

Concrete floor hardeners come in different forms, each suited for specific needs. The two main types are liquid hardeners and dry shake hardeners. Liquid hardeners, often called densifiers, are solutions that penetrate existing concrete. They react chemically to strengthen the surface. These typically contain silicate compounds like sodium, potassium, or lithium silicate. A silicate densifier works by filling pores from within.

Dry shake hardeners, on the other hand, are powders. Workers spread these powders onto fresh, wet concrete before it fully sets. Dry shake hardeners are composed of an aggregate, which can be mineral, metal, or synthetic particles. They also contain a binder, usually cement, for cohesion and workability, and often a pigment for color. The specific type of abrasive used in dry shake hardeners significantly influences their finish, behavior, and suitability for different application intensities, whether light, medium, or heavy-duty. These dry shake hardeners create an extremely tough, integral surface layer. Both types aim to improve the durability and performance of concrete flooring, but their application methods and ideal scenarios differ.

Applying Hardeners to Concrete Floors

Applying hardeners correctly ensures the best results for concrete floors. The process varies depending on whether you use a liquid densifier or dry shake hardeners.

For liquid concrete floor hardeners on existing concrete:

Preparation: Ensure the concrete surface is clean. It must be free from dust, dirt, oil, and other impurities. Use a high-pressure washer, floor scrubber, or industrial vacuum. Repair any surface defects like cracks or holes for even penetration. Check moisture levels; the surface should be slightly damp for better penetration, but not visibly wet. Maintain a stable temperature and moderate humidity, avoiding extreme weather conditions.

Timing: Liquid concrete hardeners can be applied about seven days after the concrete has hardened, allowing it to gain some strength. For optimal results, waiting 28 days is recommended as the concrete will be stronger and denser.

Application: Use a low-pressure sprayer with a fan-shaped nozzle. Evenly spray the liquid hardener onto the cleaned concrete surface. Maintain the correct distance and angle for full coverage.

Moistening: Keep the surface moist for 20 to 30 minutes after spraying to ensure full penetration. If the surface dries too quickly, lightly mist it with water.

Usage Rate: A general guideline is 0.2-0.3 liters of hardener per square meter. Specific usage varies by product and concrete absorption or surface condition.

Drying and Reaction: Allow the hardener to dry and react with the concrete. This typically takes about 24 hours for full hardening.

For dry shake hardeners, workers broadcast the powder onto freshly poured concrete. They then float and trowel it into the surface. This integrates the hardener directly into the top layer of the concrete slab.

Proper curing of the concrete is critical to the finished properties of the slab and the dry shake hardener. This includes strict planning, coordination, and control of the concrete mix, delivery schedule, ambient conditions, and final finishing procedures. For optimal cure times, follow ACI 308R, maintaining moisture and temperature for correct hydration. Seven days is a common minimum for many concrete mixes, potentially longer for blended cements, pozzolans, or in colder weather. Early drying increases the risk for dusting and scaling. For polished concrete, industry standards recommend at least a 28-day cure period before full grind or polish, unless an early polish plan is approved.

Key Benefits for Hardened Concrete Floors

Hardening concrete offers numerous advantages, transforming ordinary concrete into a high quality work surface. One of the most significant benefits is increased surface hardness. A BECOSAN® industrial concrete floor treatment enhances the resistance and hardness of concrete floors by “several points on the Mohs scale.” This makes the concrete much more durable.

This increased hardness directly translates to superior abrasion resistance. Hardened concrete flooring stands up better to heavy foot traffic, machinery, and daily wear and tear. This is crucial for industrial concrete flooring and commercial spaces where durability is paramount. The densifier fills the pores, creating a solid, less permeable surface. This reduces dusting, a common problem with untreated concrete.

Furthermore, hardened concrete floors exhibit improved chemical resistance. The densified surface is less susceptible to penetration by oils, greases, and other chemicals, making cleanup easier and preventing staining. This also enhances the floor’s resistance to micro-pitting. The denser surface also improves the overall appearance of the concrete. It creates a smoother, more uniform finish, especially beneficial for polished concrete. This makes the concrete flooring not only stronger but also more aesthetically pleasing. Ultimately, using a concrete floor hardener extends the lifespan of your concrete, reduces maintenance needs, and provides a more resilient and attractive surface.

A concrete floor hardener transforms vulnerable concrete into a durable, long-lasting surface. This densifier significantly boosts abrasion resistance, making concrete stronger. It ensures long term durability for concrete floors. The densifier protects concrete from corrosion, freeze-thaw damage, and stains, improving the concrete’s overall abrasion resistance. Choosing the right densifier is a smart investment for any concrete. This concrete will perform well, ensuring its appearance for years.

FAQ

How long does a concrete hardener last?

A concrete hardener typically lasts for the entire life of the concrete floor. It becomes a permanent part of the concrete, offering lasting densification and protection.

Can you apply a hardener to old concrete?

Yes, you can apply liquid hardeners to old concrete. First, clean the concrete surface very well. This helps the hardener penetrate and work effectively.

Does concrete hardener make the floor waterproof?

Concrete hardeners make concrete more resistant to water. They do not make concrete completely waterproof. For full waterproofing, you need a specific sealer.

See Also

Unveiling the True Distinction: Densifiers Versus Hardeners for Concrete

BANDě’s 2025 Essential Guide: Concrete Densifiers and Hardeners Explained

Essential Insights: Understanding Concrete Bonding Agents and Their Use

BANDě Concrete Densifiers: What They Are and How They Function

Your Complete Buying Guide: Densifiers, Hardeners, and Sealers for Concrete