Concrete damage, from structural cracks to surface spalling, needs effective repairs. Finding a quality concrete patch is key. We’ve curated the top epoxy concrete patch products for 2025, including BANDě Pro-Grade, Rust-Oleum Concrete Patch & Repair, and PC-Concrete Two-Part Epoxy Adhesive. They excel in durability, ease of use, and performance. This guide helps you choose the right epoxy for all your concrete repair projects.

Key Takeaways

Epoxy concrete patches are strong and last a long time. They fix cracks well and stop water from getting in.

Choose your epoxy patch based on the damage, where you will use it, and how fast it needs to dry. This helps you pick the best one.

Clean the concrete well and mix the epoxy correctly. This makes sure your repair is strong and lasts for many years.

Epoxy Concrete Patch Basics

What is Epoxy Concrete Patch

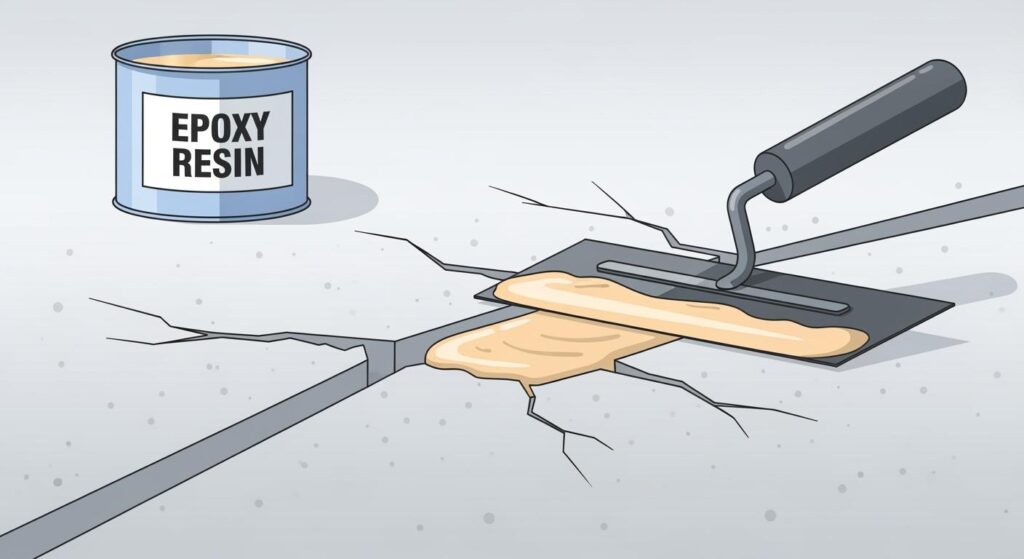

An epoxy concrete patch is a powerful solution for fixing damaged concrete. You typically find it as a two-part system. This means you mix two separate components right before you use them. Think of it like a super-strong concrete patch. For example, many high-quality patching and repair compounds are 100% solids and solvent-free. They often use advanced cycloaliphatic amine technology. This composition gives them superior adhesion and makes them ideal for various concrete repairs.

Benefits of Epoxy for Concrete Repair

Why choose epoxy for your concrete patch needs? Epoxy offers many advantages over other repair methods. First, it creates a rigid, load-bearing seal. This completely fills cracks and provides high-strength bonding. This means you get great structural reinforcement and lasting performance. Unlike hydraulic cement, which can shrink, epoxy provides reliable, long-term repairs. It also forms a non-porous, impermeable barrier over concrete. This prevents water and moisture from seeping through. You get fantastic moisture resistant technology. This makes epoxy an effective barrier against water damage. Its seamless application eliminates gaps where water could collect. Plus, epoxy offers great resistance to chemicals, oils, and stains. This multi-faceted protection boosts both durability and water resistance. You get exceptional bonding strength, restoring the structural integrity of cracked concrete. This ensures long-lasting repairs with superior quality and performance.

Choosing Your Concrete Patch

When you select an epoxy concrete patch, you need to consider several key factors. These choices ensure you get the best results for your specific project.

Damage Type and Severity

First, look closely at the damage. Is it a small surface imperfection, or do you have a deep crack? For significant damage, especially in your foundation, you need heavy-duty patching and repair compounds. These products offer superior strength. Lighter concrete patch options might work for surface issues. Different repairs demand different solutions.

Environmental Factors

Think about where you will use the epoxy. Is it indoors or outdoors? Outdoor concrete faces harsh conditions. Extreme temperatures, like freezing and thawing cycles, cause concrete to expand and contract. This thermal movement can lead to more cracking. You need materials with good resistance for reliable, long-term repairs in these climates. Choosing the right epoxy is crucial for durability and performance.

Cure Time and Working Time

Consider your project timeline. How fast do you need the repair completed?

Metric | Time |

|---|---|

Pot Life | Approximately 30 minutes |

Initial Set Time | 45-65 minutes |

Final Set Time | 55-100 minutes |

Foot Traffic | 4 hours (at 23 °C / 73 °F) |

Vehicle Traffic | 6 hours (at 23 °C / 73 °F) |

Epoxy flooring typically dries in about 72 hours for a full cure. Cold temperatures can extend this time. Look for products with quick-drying properties if time is critical for your concrete patch. |

Application and Ease of Use

How easy is the concrete patch to apply? Some patching and repair compounds are simpler for DIYers. Proper application is key for optimal adhesion and finish. You must prepare the concrete surface well, cleaning and profiling it for the best results.

Cost and Longevity

Finally, weigh the cost against the longevity. A cheaper concrete patch might not offer the same long-term strength and performance. Investing in a quality product for your concrete repairs, especially for your foundation, often saves money in the long run by preventing future repairs.

Top Epoxy Concrete Patch Products of 2025

Choosing the right concrete patch can make all the difference for your repair project. Here, we break down some of the best epoxy concrete patch products available in 2025. You will find options for various needs, from heavy-duty structural repairs to quick cosmetic fixes.

BANDě Pro-Grade Epoxy Patch

BANDě Pro-Grade Epoxy Patch stands out as a top-tier solution for serious concrete repairs. This is a robust two-part epoxy system designed for maximum strength and durability. You mix the resin and hardener just before application, ensuring a fresh, powerful bond. It often includes fine aggregate, which helps it fill larger voids and cracks effectively, providing excellent structural integrity. BANDě is highly water-resistant, making it perfect for both indoor and outdoor concrete surfaces, including your foundation. You will find it ideal for repairing spalled concrete, deep cracks, and damaged edges where you need lasting performance. Its unique selling point is its professional-grade strength, giving you confidence in long-term repairs.

Rust-Oleum Concrete Patch & Repair

Rust-Oleum Concrete Patch & Repair offers a user-friendly option for many common concrete issues. This product is typically a two-part epoxy system, providing a strong, durable repair. It is known for its ease of use, making it a great choice for DIY enthusiasts tackling various concrete repairs around the home. You can expect good water resistance from this concrete patch, which helps protect against moisture intrusion. It works well for patching small holes, cracks, and minor surface imperfections on driveways, sidewalks, and garage floors. Its key feature is its balance of quality and accessibility, giving you reliable results without needing specialized tools or extensive experience for its application.

PC-Concrete Two-Part Epoxy Adhesive

PC-Concrete Two-Part Epoxy Adhesive is a versatile and incredibly strong option for serious concrete repair. As its name suggests, it is a two-part system that creates a powerful bond. This epoxy is particularly noted for its exceptional adhesive qualities, allowing it to bond to concrete, masonry, stone, and even metal. It offers excellent resistance to water and chemicals once cured, ensuring a long-lasting repair. You will find it suitable for anchoring bolts, repairing broken concrete steps, or filling wide cracks where high strength is paramount. Its unique selling point is its incredible bonding power and versatility, making it a go-to for challenging repairs that demand superior performance.

Gorilla Glue Epoxy

Gorilla Glue Epoxy brings the trusted strength of the Gorilla brand to concrete repair. This is a clear, two-part epoxy system that delivers a strong, permanent bond. It dries clear, which is a significant advantage if you need a less noticeable repair on decorative concrete or surfaces where aesthetics matter. While it might not contain aggregate, its strong adhesive properties make it effective for smaller cracks and chips. You will appreciate its quick-setting formula, which speeds up your project timeline. It provides good water resistance, making it suitable for various indoor and outdoor applications. This epoxy is perfect for quick fixes and when you want a strong, clear finish on your concrete.

Power Patch Epoxy Kit

The Power Patch Epoxy Kit provides a comprehensive solution for concrete repairs, often including everything you need in one package. This is typically a two-part epoxy system, sometimes with aggregate included, designed for robust repairs. It offers excellent strength and durability, making it suitable for high-traffic areas and structural fixes. You can expect good resistance to chemicals and abrasion, ensuring the repair holds up over time. This kit is ideal for repairing larger spalls, deep cracks, and damaged concrete surfaces that require significant material replacement. Its unique selling point is its all-in-one convenience and reliable performance for demanding concrete repair projects.

A Note on Ardex Feather Finish: While we focus on true epoxy concrete patch products for their structural strength and durability, you might encounter Ardex Feather Finish. This product is excellent for creating a smooth, thin, aesthetic finish over concrete, especially if you plan to apply a clear coat or other flooring on top. However, it is not an epoxy and does not offer the same structural strength or water resistance as the epoxy options listed above. Use it for cosmetic improvements, not for load-bearing repairs or areas needing significant moisture protection.

BANDě Pro-Grade Epoxy Patch Review

Features and Ideal Uses

BANDě Pro-Grade Epoxy Patch offers a premium solution for your toughest concrete repairs. This professional-grade epoxy is a robust two-part system. You mix the resin and hardener right before application. This ensures maximum strength and durability. You will find it perfect for significant damage, like deep cracks in your foundation or spalled concrete surfaces. Its robust formula provides exceptional bonding strength, making it ideal for structural concrete crack repair. You can use it for driveways, garage floors, and even industrial settings where heavy loads are common. This concrete patch excels where you need a permanent, high-performance repair that withstands harsh conditions. It also offers excellent resistance to chemicals and abrasion.

Performance and User Feedback

Users consistently praise BANDě for its outstanding performance. You get a repair that truly lasts. Many report that the cured epoxy is incredibly hard and resistant to wear, chemicals, and moisture. Its ease of application also receives positive feedback, even for complex repairs. People appreciate how it restores the integrity of damaged concrete, giving them confidence in the longevity of their repairs. They often highlight its ability to create a seamless bond, preventing further deterioration. When you need a quality solution that delivers reliable strength and lasting results, BANDě Pro-Grade Epoxy Patch is a top choice. It stands up to heavy use, ensuring your concrete stays solid and secure for years to come.

Effective Epoxy Application for Concrete Crack Repair

Surface Preparation Steps

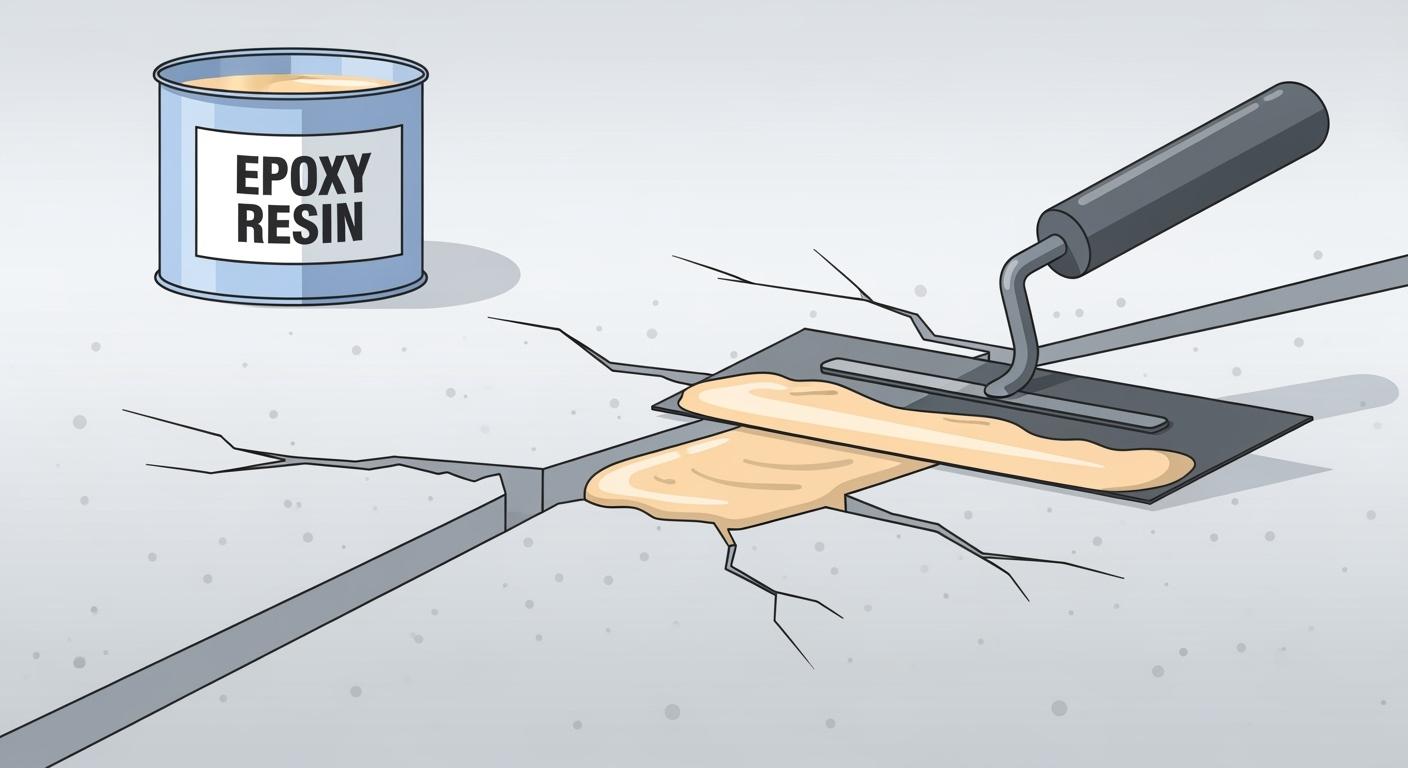

Before you apply any concrete patch, proper surface preparation is crucial for a quality, lasting repair. First, inspect your concrete surface carefully. Look for any damage, moisture issues, or oil stains. You must address moisture before you start. Next, clean the surface thoroughly. Remove old coatings, grease, and dust using degreasers and vacuums. For heavy stains, you might need special solvents. Then, repair any cracks or imperfections. Use patching and repair compounds to fix spalled areas or chips. This ensures a smooth surface for your concrete crack repair. After cleaning, profile the surface. You can use diamond grinding or shot blasting to create a textured profile. This helps the epoxy bond properly. Always check moisture levels again. If you find excess moisture, use primers or vapor barriers. Finally, apply a primer to seal the concrete and improve adhesion. This step is vital for any concrete surface repair, especially for your foundation.

Mixing and Application Techniques

Mixing your concrete patch correctly is just as important as preparation. Epoxy systems are typically two-part. You must proportion and mix Part A and Part B at the correct ratios. Incorrect ratios can lead to poor performance or failure to cure. First, mix Part A and Part B separately. Then, combine them and mix thoroughly for at least three minutes. Use a low-speed motor with a Jiffy mixer or paddle. Remember to scrape material from the walls of your mixing container. This ensures homogeneity. Only mix as much material as you can use within its pot life. This prevents waste and ensures optimal application for your repairs. For best results, condition your materials to room temperature. Warmer material reacts and cures faster.

Curing and Post-Application Care

After application, proper curing ensures your concrete patch lasts. Environmental conditions play a big role. You need to ensure the substrate temperature is at least 3°C (5°F) above the dew point. This prevents condensation, which can cause poor adhesion or bubbling. High humidity can also prolong curing time. It might even make the mixture waxy or oily. Optimal curing temperatures range from 60°F to 90°F (15°C to 32°C). This allows for proper chemical reactions. High temperatures can shorten the pot life of your epoxy. High humidity, especially above 70%, delays curing and traps moisture. Following these guidelines helps you achieve a durable repair and effective sealing concrete cracks.

Choosing the right epoxy concrete patch is crucial for your project. Consider your concrete damage and environmental factors. Top products like BANDě offer excellent repair. Assess your needs carefully and apply your chosen concrete patch correctly for lasting results. Tackle your concrete crack repair with confidence using the right epoxy!

FAQ

Can I paint over an epoxy concrete patch?

Yes, you can paint over most epoxy concrete patches. Always check the product instructions first. Allow the patch to fully cure before applying any paint or coating for the best results.

How long does an epoxy concrete patch last?

A properly applied epoxy concrete patch can last for many years, often as long as the concrete itself. Its longevity depends on surface preparation, application, and environmental conditions.

Is epoxy concrete patch waterproof?

Yes, epoxy concrete patches create a strong, non-porous barrier. This makes them highly water-resistant and effective at preventing moisture from penetrating the repaired area.

See Also

Selecting the Ideal BANDě Concrete Patching Compound for Your Project

Ultimate Guide: Mastering Cement Crack Sealer for Durable Repairs

BANDě’s Guide: Choosing the Perfect Cementitious Crack Sealer

Essential Guide: Selecting the Best Concrete Protective Sealer

Choosing the Optimal Concrete Densifier for Your Warehouse Floor