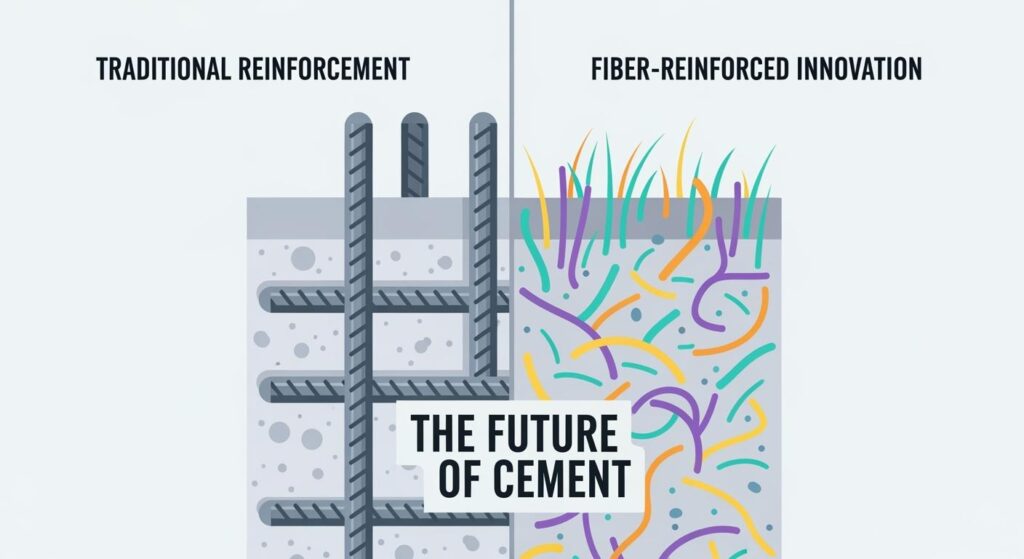

Traditional steel has long dominated reinforcing concrete, a foundational element in modern construction. However, fiber reinforced technologies emerge as significant alternative construction materials. These advanced fiber solutions demand detailed comparison. This blog provides a comprehensive comparison of these cement reinforcement methods, assisting informed decision-making for various construction projects.

Key Takeaways

Fibre reinforcement offers better corrosion resistance and is much lighter than steel. This makes structures last longer and easier to build.

Fibre reinforcement is often more sustainable. It uses recycled materials and reduces carbon emissions, helping the environment.

The best choice between steel and fibre depends on the project. Consider what the project needs, how much it costs, and its environmental goals.

Traditional Steel Reinforcement

Steel Composition and Grades

Traditional steel has long served as the backbone of concrete structures. Engineers primarily use two main types of steel for reinforcement: reinforcing mesh and reinforcing bar. Reinforcing bars, commonly known as steel rebar, are cylindrical steel rods available in various diameters. They are crucial for beams, columns, foundations, and other load-bearing elements. Different grades of steel rebar cater to specific project needs. Mild steel rebar offers good strength and remains cost-effective for everyday construction. High-strength deformed (HSD) rebar provides superior tensile strength, making it suitable for projects demanding significant structural integrity. For challenging environments, epoxy-coated steel rebar features a protective coating against rust and corrosion, ideal for humid or coastal areas. Stainless steel rebar offers exceptional corrosion resistance, while galvanized rebar, coated with zinc, provides enhanced protection in harsh conditions.

Manufacturing and Standards for Steel Rebar

The manufacturing of steel rebar involves several key processes. These include cutting, bending, and welding, often performed using specialised machinery like rebar cut and bend machines or wire mesh welding lines. Off-coil processing and rolling lines also play a significant role in shaping the steel. Automation in rebar factories ensures efficiency and precision. Quality standards for deformed bars vary across countries. However, the International Standards Organisation (ISO) oversees and maintains these local standards, ensuring global consistency and reliability for steel rebar products.

Historical Applications and Proven Performance

The history of traditional steel reinforcement demonstrates its proven performance. Sir John Monash pioneered reinforced concrete in Australia, with his firm securing a license for the Monier system in 1897. His company designed and built some of Australia’s earliest reinforced concrete structures, including approximately 20 arch bridges in Victoria in the late 1890s, such as the Hawthorn Bridge (1899). The Johnston’s Creek Sewer Aqueduct in Annandale, completed in 1896, stands as Australia’s first reinforced concrete structure and remains functional today. Later, extensive concrete and steel rebar work featured in the Sydney Harbour Bridge approaches (1932) and the underground City Circle railway. Modern projects like the Sydney Harbour Tunnel (1992) utilised prefabricated steel reinforcement cages. Australian engineers also contributed to advanced techniques, including high-strength steel rebar and the use of galvanized rebar for improved durability in marine environments, notably in parts of the Sydney Opera House.

Fibre Reinforcement Technologies

Types of Fibres in Cement Reinforcement

Fibre reinforcement introduces various materials into concrete to enhance its properties. Engineers use several types of fiber for cement reinforcement. These include:

Carbon Fibre: This fiber offers a high strength-to-weight ratio, high-temperature resistance, and chemical tolerance. It is brittle but finds use in precast concrete and shows potential for fiberglass rebar and mesh.

Natural Fibres: Historically, people used materials like straw and horsehair. Today, cellulose fibers from pine trees are common due to their low cost and abundance.

Steel Fibres: These enhance resistance to cracking, fatigue, flexural strength, tensile strength, and durability in Steel Fibre Reinforced Concrete (SFRC).

Glass Fibres: Used in Glass Fibre Reinforced Concrete (GFRC), this fiber is lightweight. It often features in building facades and decorative elements. Specifically, fiberglass rebar, a type of GFRP, offers excellent corrosion resistance. This GFRP material provides a durable solution.

Polypropylene Fibres: This synthetic fiber primarily reduces cracking from drying shrinkage. Longer fibres can also increase concrete strength.

Plastic Fibres: These serve as secondary reinforcement to reduce shrinkage and micro-cracking. They are cost-effective and easy to add to concrete mixes.

Fibre Material Properties

Each fiber type brings distinct material properties to reinforced concrete. Carbon fibers, for instance, are high-strength fibers used in Fibre-Reinforced Polymers (FRP). These composites, which also include glass or natural fibers, leverage advantages like fiber reinforcement, strain resistance, and anisotropy. This contributes to benefits such as lightweight construction, corrosion resistance, and customised designs. For example, fiberglass rebar (GFRP) exhibits a high strength-to-weight ratio and is entirely corrosion-resistant. This GFRP also offers superior performance in certain environments.

Polypropylene fibers also offer specific characteristics:

Property | MPM (Polypropylene) | ENVIROMESH® SMP65 (Polypropylene) |

|---|---|---|

Material | Polypropylene | Polypropylene |

Min Tensile Strength | 500 MPa | 550 MPa |

Young’s Modulus | 10.0 GPa | N/A |

Specific Gravity | N/A | > 0.91 g/cm³ |

Aspect Ratio | 58 | 100 |

These properties highlight the versatility of fiber options. GFRP, including fiberglass rebar, provides a strong alternative to traditional steel. The benefits of GFRP are clear in many applications.

Integration and Dispersion Methods

Integrating fibres into concrete mixes requires careful attention. Manufacturers typically add fibres during the mixing process. This ensures even dispersion throughout the concrete matrix. Proper mixing prevents clumping and guarantees the fibres can effectively reinforce the material. For example, when using fiberglass rebar, it replaces steel rebar in the formwork. For short fibres, uniform distribution is key to achieving the desired mechanical properties in the final reinforced product. This method ensures the concrete benefits fully from the added fiber. GFRP products, like fiberglass rebar, are installed similarly to steel.

Fiber-Reinforced Polymer vs Steel: Strength and Durability

This section directly compares the performance metrics of both reinforcement types, highlighting their distinct advantages and limitations in terms of strength and durability. The choice between fiber-reinforced polymer vs steel significantly impacts a structure’s long-term performance.

Tensile Strength and Load Capacity

Tensile strength is a critical factor in reinforcement materials. Steel rebar typically offers a tensile strength of approximately 450 MPa. In contrast, fiberglass rebar, a type of GFRP, exhibits significantly higher tensile strength. Its values range from 800–1200 MPa, depending on the diameter. This means GFRP rebar is 2 to 2.5 times stronger than metal in tension.

Property | Steel Rebar | GFRP Rebar |

|---|---|---|

Tensile Strength | ~450 MPa | 800–1200 MPa |

FRP specimens have consistently outperformed traditional steel in various tests for equal diameter bars, demonstrating superior load capacity. This high tensile strength makes fiberglass rebar an attractive option for projects demanding exceptional structural integrity.

Corrosion Resistance and Longevity

Corrosion resistance is a major differentiator between these materials, directly impacting longevity and durability. FRP rebar is a non-metallic option. It resists corrosion and offers excellent durability, making it an ideal choice for long-term applications in harsh marine environments. Mateenbar™ FRP reinforcement is engineered to perform in challenging and corrosive environments. It provides durability and corrosion-resistance, with a 100-year design life cycle, where steel rebar can fail. It offers exceptional resistance to water and salinity. It does not rust, leach, or cause concrete cancer.

In contrast, steel rebar is susceptible to corrosion, especially in coastal areas where saltwater accelerates the deterioration process. This corrosion can lead to the expansion of the steel rebar, causing cracking and spalling of the surrounding concrete. This weakens the structure and necessitates costly repairs. While traditional steel is known for its strength and durability, its integrity can be compromised by corrosion if not adequately protected or maintained. This is a critical factor when comparing it with GFRP in terms of long-term performance and durability in corrosive environments. The use of corrosion-resistant materials like fiberglass rebar significantly enhances the longevity of reinforced concrete structures.

Crack Control and Post-Cracking Behaviour

Both steel and fiber reinforcement play crucial roles in controlling cracks within concrete. Steel rebar provides ductility, allowing reinforced concrete to deform significantly before failure. This gives warning signs of structural distress. Fibers, when uniformly dispersed throughout the concrete matrix, help to distribute stresses more evenly. This limits the propagation of micro-cracks and improves the material’s overall integrity. This enhanced crack control contributes to the long-term durability of the concrete element.

Weight, Handling, and Flexibility

The physical properties of reinforcement materials directly affect construction logistics. Fiberglass rebar, specifically MST-BAR, is one-quarter the weight of steel rebar while offering equivalent reinforcement capacity. This significant weight reduction offers numerous advantages. Fiberglass rebar can be up to 75% lighter than traditional metal rebar.

This reduced weight translates into easier handling and greater flexibility on site.

Quicker Placement: Fibre is pre-mixed, enabling rapid delivery and minimal handling on site.

Lower Labour Demands: By removing rebar, the complexity and time needed for labour on site are greatly reduced.

Easier Logistics: Avoiding the need for bulky steel transport helps to minimise congestion and storage issues.

Enhanced Quality Control: Factory-controlled mixing ensures consistency and reduces variability, leading to fewer delays.

A key enabler of this rapid installation is the sophisticated attachment systems employed with lightweight reinforced panels. For instance, ShapeShell™ products are designed with engineered mounting systems that incorporate a high degree of adjustability. These systems allow for up to 20 mm of on-site adjustability. This is crucial for accommodating typical building tolerances and ensuring precise alignment of the panels to the substructure. This adjustability eliminates the need for time-consuming shimming or bespoke corrections, allowing for faster and more accurate fixing. The combination of modular design, prefabrication, and intelligent attachment systems collectively drives down installation timeframes. This accelerated installation directly impacts overall project schedules, enabling earlier completion, reducing overhead costs, and facilitating quicker project handover. Fibre mixes reduce prep work and improve finish consistency, helping projects stay on programme and within budget.

Flexural Strength and Impact Resistance

Reinforced concrete slabs incorporating steel fibres or steel mesh demonstrate a significant increase in flexural strength. Steel fibers can significantly increase the first-crack and ultimate flexural strength of concrete, achieving improvements of 1.5 to 3.0 times over plain concrete, especially with higher dosage rates of shorter fiber products. This enhancement in flexural strength also contributes to improved fatigue resistance, allowing for potentially thinner slabs (up to 25% thinner) for the same load-carrying capacity under dynamic conditions. Steel fibers reinforce concrete in its hardened state, improving its overall strength and durability by holding cracks tightly due to their high modulus of elasticity and tensile strength. GFRP also contributes to improved flexural performance and impact resistance.

Material | |

|---|---|

PP fibers | 28% |

Steel fibers | 47% |

Steel meshes | 79% |

While steel meshes show the highest improvement in flexural cracking strength, steel fibers offer substantial benefits. The compressive strength of concrete is also indirectly enhanced by the improved crack control and overall integrity provided by both steel and fiber reinforcement.

Cost and Economic Considerations

Upfront Material and Installation Costs

The financial implications of choosing between steel and fibre reinforcement begin with upfront material and installation costs. Steel rebar generally has lower upfront material costs. In contrast, fiberglass rebar, a type of GFRP, typically presents a higher upfront cost per unit. The cost of fiberglass rebar can be 1.5 to 2 times higher than steel rebar per unit. However, installation costs often tell a different story. Fibre reinforcement can significantly reduce overall project expenses. For example, a standard culvert project, which would typically require a four-man crew two to three days to complete using traditional methods, was finished by one operator in just one day using Barchip’s synthetic fibre reinforced shotcrete. This demonstrates considerable labour savings.

In another instance, a project replaced 438.7 tonnes of steel reinforcement with only 19 tonnes of BarChip48 macro synthetic fibre. This led to simplified logistics and faster construction. Barchip’s synthetic fibre concrete reinforcement can reduce construction times, labour, and material costs. It also significantly decreases ongoing maintenance costs by eliminating time-consuming steel processes. Carbon fibre reinforcement, while having a higher material cost upfront, offers rapid installation, curing in 24-72 hours compared to weeks for steel plate bonding. This speed contributes to a lower lifecycle cost. Carbon fibre reinforcement typically costs £300–£800/m², depending on complexity, which is significantly less than demolition.

Long-Term Maintenance and Lifecycle Costs

Long-term maintenance and lifecycle costs represent a crucial factor in the economic comparison. While steel rebar may be cheaper initially, it can lead to expensive structural failures and ongoing maintenance needs. In contrast, Fibre Reinforced Polymer (FRP) components do not require the same level of ongoing maintenance and repairs. This leads to savings on labour and material costs and avoids repair downtime. FRP reinforcement systems are also more durable, extending the life expectancy of concrete structures by over 50 years, further reducing long-term costs.

Structures reinforced with carbon fibre generally incur lower long-term maintenance and repair expenses compared to those using traditional reinforcing steel. This is primarily because carbon fibre is inherently resistant to corrosion, a common issue for steel that leads to ongoing maintenance and repair costs. The durability of carbon fibre significantly reduces the need for frequent interventions, contributing to its long-term cost-effectiveness. FRP’s corrosion resistance makes it ideal for harsh environments, unlike steel, which is vulnerable to rust, especially in coastal or chemical-exposed areas. Steel structures often require ongoing maintenance to combat corrosion, adding to long-term costs, whereas GFRP requires minimal to low maintenance, enhancing its longevity.

Labour Efficiency and Project Timelines

Fibre reinforcement significantly impacts labour efficiency and project timelines. It can completely eliminate steel fabric reinforcement, saving on both materials and labour. This increases the speed of construction, saving time and reducing costs. The simplicity of construction leads to simpler joints and no more errors in steel fabric positioning. Projects benefit from guaranteed faster install times, less material handling, and reduced overall installation efforts. The use of fibre reinforcement has been shown to achieve a 15-20% reduction in costs, partly due to less labour and material handling associated with faster slab completion times. This efficiency contributes to quicker project delivery and reduced overheads.

Sustainability and Environmental Impact

The environmental impact of construction materials is increasingly important, influencing cost and economic considerations through evolving sustainability standards. The construction sector accounted for over 34% of energy demand and around 37% of energy and process-related CO2 emissions in 2021. Raw resource use is predicted to double by 2060, with steel, concrete, and cement being major contributors to greenhouse gas emissions. Materials used in building construction already account for approximately 9% of overall energy-related CO2 emissions.

Fibre reinforcement offers significant environmental advantages. Dramix® fibres enable thinner concrete sections and require less steel compared to traditional reinforcement, leading to a significant reduction in CO2 emissions. Dramix® reduces concrete thickness by 10-25% and steel usage by 30-50%. Dramix® reinforced concrete elements offer increased lifespan and lower maintenance costs, contributing to sustainability by reducing the need for frequent replacements and repairs. Dramix® also requires significantly fewer deliveries compared to bulky mesh reinforcement, improving transportation efficiency and reducing associated environmental impacts.

Enviromesh solutions, which use fibres made from 100% recycled plastic, reduce CO2 emissions by up to 94%. Up to 94% water is saved in the manufacturing process of Enviromesh fibres. Substantial reduction in fossil fuel consumption is achieved due to easier transportation of material. Enviromesh has used 1000 tonnes of recycled plastic, equivalent to the plastic waste produced by 6,400 Australians in a year. eMesh has resulted in a reduction of 22,000 tonnes of emissions, equivalent to removing 4,800 cars from roads for one year. eMesh has saved 4,400 tonnes of fossil fuels and 348,000 cubic metres of water (equivalent to 139 Olympic-sized swimming pools). Enviromesh offers sustainable fibre reinforced concrete solutions that replace steel mesh, reducing carbon emissions, increasing productivity, and enhancing on-site safety by eliminating issues like steel corrosion and reducing concrete cracks, leading to less ongoing maintenance and improved durability.

Fibreglass Reinforced Plastic (FRP), including fiberglass rebar, offers exceptional durability and resistance to corrosion, leading to a longer lifespan (up to 5 times greater than steel in some cases). This longevity reduces the need for frequent replacements, repainting, recoating, and repairs, thereby minimizing waste and resource consumption. GFRP is significantly lighter than traditional construction materials like steel, which reduces transportation energy and costs. Transporting lighter materials requires less fuel, resulting in lower greenhouse gas emissions. Certain types of GFRP can be recycled, contributing to a circular economy. Advancements in recycling technologies are making this increasingly feasible, reducing the need for virgin raw materials and minimizing waste. The overall durability and reduced maintenance of GFRP contribute to its environmental benefits and long-term economic viability.

Applications and Suitability

This section outlines where each reinforcement type excels in modern construction, guiding material selection for specific project demands.

Structural Concrete Elements

For structural concrete elements, the choice between steel and fibre reinforcement significantly impacts performance. Macro Synthetic Fibre Reinforced Concrete (MSFRC) offers a practical alternative to traditional steel rebar in precast elements like pits, headwalls, and traffic medians. It simplifies casting processes by eliminating steel fixing, providing superior crack control and durability without corrosion. This contrasts with traditional steel mesh, which can suffer from corrosion, leading to ‘concrete cancer’. RePoly RF47 Macro Synthetic Fibre Reinforced Concrete, for instance, is an ideal choice for traffic medians, offering durability, safety, and cost efficiency. It eliminates the need for steel mesh, reducing setup time and engineering inspections, which cuts down on road closure times. This type of fibre reinforcement enhances structural integrity, especially post-cracking, and significantly lowers the CO2 footprint compared to steel rebar.

Industrial Flooring and Pavements

Fibre reinforcement offers distinct advantages for industrial flooring and pavements. Unlike 2-dimensional traditional steel mesh, fibre reinforcement provides a 3-dimensional network across the entire concrete cross-section. This improves ductility and crack control, reducing propagation and extending service life. This leads to reduced construction time and cost. The elimination of corrosion risk makes fibre-reinforced concrete ideal for heavy loads and traffic. Dramix® 4D Series fibres are engineered for heavy-duty pavements in harbours and industrial areas, creating durable, liquid-tight floors with high impact resistance. Dramix® 3D Series offers a cost-efficient solution for solid, durable, and virtually maintenance-free saw-cut floors, eliminating the need for mesh or other traditional reinforcement. This allows for thinner pavement sections and a lower embodied carbon footprint.

Precast Concrete Applications

Fibre reinforcement offers numerous advantages in precast concrete applications. It eliminates the need for steel rebar preparation and installation, streamlining the process and reducing labour costs. This leads to significant time savings and better safety on site by mitigating risks associated with handling traditional steel reinforcement. Fibre reinforcement also reduces waste, as it eliminates off-cut waste common with steel mesh. It offers a cheaper alternative to steel rebar, leading to substantial savings and a lower carbon footprint. Fibre-reinforced concrete enhances structural integrity and ductility by reinforcing the entire cross-section of concrete elements. It provides immunity to corrosion, leading to longer-lasting structures, unlike steel rebar. This simplifies the casting process for precast concrete, offering enhanced crack control, improved durability, and simplified production, especially for complex 3D elements. The use of GFRP in precast elements ensures corrosion-free performance and enhanced flexural strength.

Specialist Environments and Blast Resistance

In specialist environments, such as those requiring blast resistance, fibre-reinforced concrete demonstrates superior performance. The inherent properties of fibre reinforcement, including enhanced crack control and improved impact resistance, contribute to the development of safety guards using blast-resistant concrete. This makes it a preferred choice over traditional reinforced concrete in high-risk applications. The ability of GFRP to absorb and dissipate energy more effectively than steel rebar helps maintain structural integrity under extreme loads.

Architectural and Aesthetic Considerations

The choice of reinforcement also influences architectural and aesthetic outcomes. Fibre reinforcement, particularly GFRP, allows for greater design flexibility due to its lightweight nature and corrosion resistance. This enables the creation of thinner, more intricate concrete elements without concerns about rust staining or spalling, which can occur with steel rebar. The improved crack resistance offered by fibre-reinforced concrete also contributes to more attractive and aesthetically pleasing structures, reducing the need for disruptive maintenance and ensuring a pristine finish.

Future Trends and Hybrid Solutions

Combining Steel and Fibre Reinforcement

The construction industry increasingly explores hybrid solutions, blending traditional steel with modern fiber reinforcement. This approach offers significant advantages. It provides controlled cracking, managing crack formation under service stresses. Hybrid designs also allow for reduced joints or even joint-free structures. Furthermore, they significantly reduce the need for conventional reinforcing materials, leading to cost savings and faster construction. However, challenges exist. Under-engineered designs can result in thinner slabs that underperform. Site variability and unpredictable conditions are often overlooked. Ambiguity around design ownership also shifts responsibility. Risks associated with low-dosage steel (SFRC) include inconsistent distribution. A lack of long-term performance data for these new hybrid designs creates uncertainty about their service life.

Emerging Fibre Technologies and Research

Innovations in fiber technology continue to advance cement reinforcement. Macro synthetic fiber stands out as a low-carbon reinforcement system for concrete track slabs. It replaces steel, offering reduced construction time, improved crack control, and corrosion elimination. Carbon Fibre Reinforced Polymer (CFRP) presents a revolutionary alternative for strengthening existing structures. Its exceptional strength-to-weight ratio and durability make it ideal. It provides a cost-effective and minimally destructive method to improve beams, slabs, and columns. Researchers also explore new fiber cladding solutions for thermal performance and fire resistance. Efforts focus on sustainability, using recycled fibers and bio-based alternatives. Future trends include self-healing materials and AI-assisted manufacturing for optimized fiber placement.

Smart Concrete and Sensor Integration

The future of concrete structures also involves smart concrete and sensor integration. Embedding sensors within reinforced concrete allows for real-time monitoring of structural health. This technology can detect early signs of stress or cracking, enabling proactive maintenance. Such integration enhances the longevity and safety of infrastructure, providing valuable data for future design improvements in cement reinforcement.

Steel and fibre technologies offer distinct advantages for cement reinforcement. Steel provides proven performance; fibre enhances durability and longevity. The optimal choice for any construction project depends on specific requirements, budget, and sustainability goals, ensuring long-term durability. Future construction will likely see integrated, hybrid solutions. Readers must weigh all factors.

FAQ

What is the primary advantage of fibre reinforcement over steel?

Fibre reinforcement offers superior corrosion resistance and a significantly lighter weight. This reduces maintenance needs and simplifies handling on construction sites.

Is fibre reinforcement a more sustainable option than traditional steel?

Yes, many fibre types, especially those from recycled plastics, significantly reduce CO2 emissions and resource consumption. They also contribute to longer-lasting structures.

Can fibre reinforcement be used in all types of concrete structures?

Fibre reinforcement suits many applications, particularly industrial flooring and precast elements. Engineers must evaluate specific project requirements and structural demands for suitability.

See Also

Comparing Industrial Floor Hardeners: Your Definitive Guide for 2025

BANDě’s Essential 2025 Handbook for Concrete Densifiers and Hardeners

Selecting the Optimal Cementitious Repair Mortar: A 2025 Buyer’s Guide

A Comparative Handbook: Selecting the Premier Floor Hardener for 2025

Understanding Concrete Bonding Agents: Essential Insights for Construction Professionals