A crystal floor hardener makes floors strong. You want clear resin for crafts. You pick epoxy or UV resin. The best resin changes for each project. This guide shows how resins are different. Resins called ‘crystal clear’ are good. ‘Non-yellowing’ resins are also good. They are best for clear projects.

Key Takeaways

Epoxy resin works for big projects. It takes longer to dry. It is cheaper for large amounts.

UV resin works for small projects. It dries very fast under UV light. It costs more than epoxy resin.

Choose your resin based on project size, drying time, and cost. Always use safety gear when working with resin.

Epoxy Resin for Clear Projects

Epoxy Resin Basics

Epoxy resin is popular. Many crafts use it. You mix two parts. One is resin. One is hardener. They react together. This makes liquid turn solid. It becomes strong and clear.

Epoxy Pros for Clarity

Epoxy resin is very clear. Use it for big items. Use it for deep pours. It makes a strong finish. Many good epoxies have UV protection. These stop yellowing. They keep resin clear. Sunlight won’t turn it amber. Your projects stay clear. Epoxy is cheap for big jobs.

Epoxy Cons for Clarity

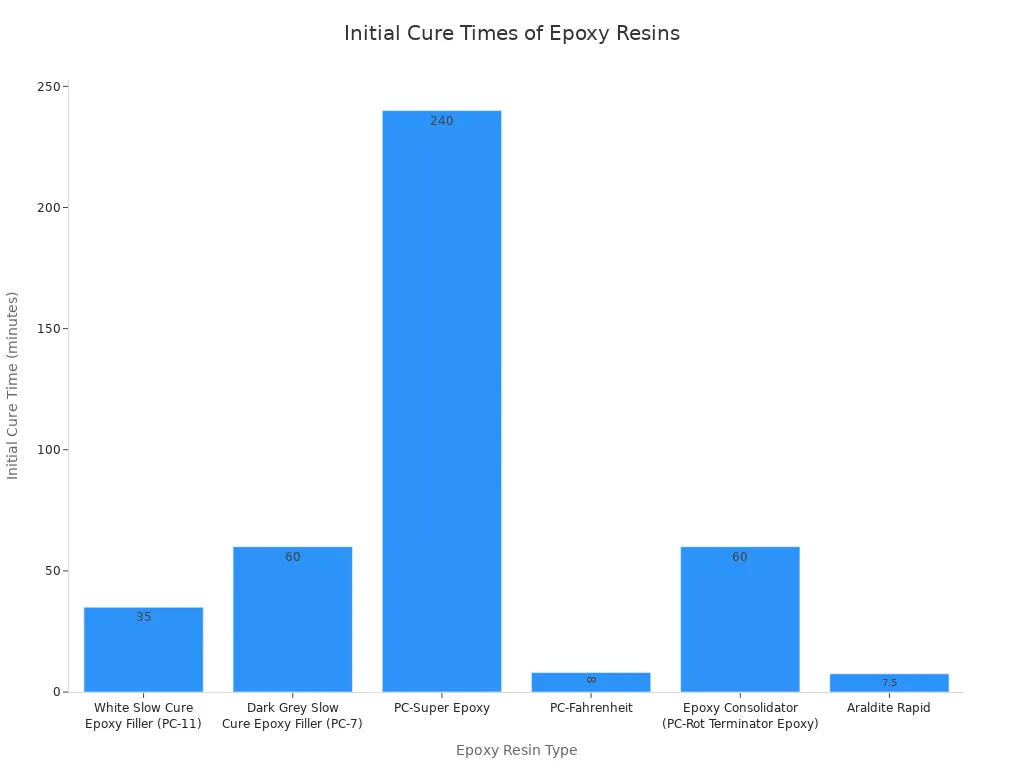

Epoxy resin has some problems. It takes long to dry. Some need 24 hours. Full drying takes 7 days. See cure times below.

Epoxy Resin Type | Initial Cure Time | Full Cure Time |

|---|---|---|

White Slow Cure Epoxy Filler (PC-11) | 30-40 minutes | 10-12 hours |

Dark Grey Slow Cure Epoxy Filler (PC-7) | 60 minutes | 24 hours |

PC-Super Epoxy | 3-5 hours | N/A |

PC-Fahrenheit | 8 minutes | 60 minutes |

Epoxy Consolidator (PC-Rot Terminator Epoxy) | 60 minutes (work time) | 24 hours |

Araldite Rapid | 5-10 minutes | Overnight (gains strength) |

Approximately 24 hours | Approximately 7 days |

Bubbles can form. Mix parts carefully. If not, it won’t dry right. Some epoxy yellows over time. This happens with too much sun. Good products resist this. Puduo 3x is one. It stays clear. It resists bubbles. Fast Set Epoxy Resin dries fast. It handles heat well.

Epoxy Use Cases

Epoxy resin works for big projects. River tables are popular. Use it for large castings. It coats countertops well. It works for bar tops. Thick jewelry uses it. Floors in factories use it. It fixes boats with fiberglass. Epoxy resin is useful. It helps with many crafts.

UV Resin for Clear Projects

UV Resin Basics

UV resin is another choice. It helps with clear crafts. This resin is one liquid. You do not mix parts. UV resin has a liquid part. It also has a photoinitiator. UV light starts the hardening. It makes the photoinitiator work. This causes a chemical change. The liquid turns solid. UV light makes it harden fast. This happens when UV light hits it. The liquid resin becomes solid quickly. Use 405nm for best curing. Use LED UV lights. New UV machines use LED lights. They use 405nm for best results.

UV Pros for Clarity

UV resin dries very fast. It gets hard under UV light. You won’t make mixing mistakes. It is great for small parts. You will see fewer bubbles. Apply it in thin layers. It starts very clear. Fast drying helps with small details. You can place parts exactly. Then you glue them fast. This stops them from moving. You know when it will dry. This means less fixing. Fast drying saves time. It makes more things faster. This is key for many small parts. UV glues get strong in seconds. This helps factory lines work well.

UV Cons for Clarity

UV resin has some bad points. You can only pour thin layers. It costs more than epoxy resin. You need a special UV lamp. This resin can turn yellow faster. This happens if it’s not UV stable. It also smells strong.

UV Use Cases

UV resin is great for small things. You can use it for small jewelry. It works well for layers. Its exactness is key. This is for things like sensors. It is also used in tiny cameras. You can use UV resin for many small projects.

Epoxy vs. UV Resin: Key Differences

You will find many key differences. These are between epoxy resin and UV resin. Knowing these helps you choose. Pick the right material for your projects.

Curing Time Comparison

You need to understand curing time. This is a main difference. It is between these two resins. Epoxy resin needs more time. It takes hours or even days. You might wait 24 hours. Then your epoxy resin is tack-free. Full cure can take seven days. UV resin cures fast. It hardens under UV light. You shine the light. Your UV resin hardens quickly. This speed is a big plus. It helps with quick projects.

Project Size and Depth

Think about your project size. Epoxy resin works well. It is good for large, deep pours. You can make thick river tables. Or make large castings. UV resin has limits. Use UV resin for small things. Use it for thin layers. Pouring it too thick is bad. It will not cure right. The UV light cannot reach deep. It cannot get into the UV resin.

Ease of Use and Mixing

Mixing is another point. Epoxy resin needs exact mixing. You combine two parts. Use an exact ratio. This is often 1:1 or 2:1. Some can be 3:1, 4:1, or 5:1. You must follow these rules. The resin and hardener react. They cure chemically. A wrong ratio stops curing. Your material might stay sticky. It could be gummy or soft. It will never get hard. This hurts its strength. It also hurts its durability. The chemical reaction needs balance. UV resin does not need mixing. You pour it from the bottle. This makes it easy to use. You avoid all mixing errors.

Durability and Longevity

Think about how strong your items need to be. Epoxy resin is usually stronger. It is for large items. It makes a very tough surface. UV resin is good for small items. But it can break easier. You can see strength differences:

Resin Type | Tensile Strength (MPa) | Hardness (Shore D) |

|---|---|---|

20-35 | 70-90 | |

UV Resin | >25 | Varies (up to high-modulus rigid) |

Epoxy resin is often harder. This means it resists dents better. Epoxy resin is usually 80-85 Shore D. UV resin’s hardness changes. Some UV resin is very stiff.

Cost Effectiveness

Cost is always important. It matters for your projects. Epoxy resin costs less. It is cheaper for big amounts. You buy it in bigger containers. This makes the price per ounce lower. UV resin costs more. It is more expensive per volume. But you might waste less. This is for small projects. You only use what you need. You do not mix too much resin.

Yellowing and UV Resistance

Both resins can turn yellow. This happens over time. It is from UV light. Formulas are very different. Good epoxy resins have UV blockers. These stop yellowing. They protect your projects. UV resin can yellow faster. This is true if it’s not UV stable. You can use curing boxes. These make resin cure faster. They give steady warmth or UV light. This helps resin be consistent.

Choosing Your Best Resin

You have learned about epoxy resin and uv resin. Now, you need to pick the right resin. The best resin for your project depends on what you want to make. Think about your specific needs. This guide helps you make an informed choice about your resin.

Consider Project Scale

Your project’s size matters. For large projects or deep pours, epoxy resin is usually best. It handles volume well. If you are making small, intricate items, uv resin works better. UV resin cures quickly in thin layers. It is perfect for tiny details.

Consider Your Timeline

How fast do you need your projects done? Epoxy resin takes time to cure. You will wait hours or even days for it to fully harden. If you need quick results, uv resin is your friend. UV resin cures in seconds under a UV light. This speed is great for fast-paced projects.

Consider Your Budget

Cost is a big factor. Look at the price per volume. For larger projects, epoxy resin is more cost-effective. You buy it in bigger amounts. This lowers the unit price. UV resin costs more per ounce. However, you might use less for small projects. This reduces waste.

You can see the cost difference in this table:

Resin Type | Product | Quantity (grams) | Price (Rs.) | Calculated Cost for 1000g (Rs.) |

|---|---|---|---|---|

Epoxy Resin | EPOKE EFX RESIN + HARDNER | 1500 | 1,528.00 | 1018.67 |

Epoxy Resin | EPOKE RESIN + HARDENER | 1200 | 1,008.00 | 840.00 |

UV Resin | UV CURABLE RESIN SOLUTION HARD GLUE | 500 | 1,634.00 | 3,268.00 |

UV Resin | UV CURABLE RESIN SOLUTION HARD GLUE | 200 | 656.00 | 3,280.00 |

UV Resin | UV CURABLE RESIN SOLUTION HARD GLUE | 100 | 328.00 | 3,280.00 |

This table shows you the cost difference. For example, 1000 grams of epoxy resin can cost around 840 to 1018 Rs. The same amount of uv resin can cost over 3000 Rs. This makes uv resin significantly more expensive per gram.

Consider Experience Level

Your experience level also guides your choice. UV resin is often easier for beginners. You do not mix parts. This removes a common error source. Epoxy resin requires precise mixing. Beginners need to be careful.

Safety is always important. You must protect yourself when working with any resin.

Gloves

Safety glasses

Respirator or mask

Long sleeves

Protective clothing

Always work in a well-ventilated area. Avoid direct skin contact with the resin and hardener. Keep away from open flames. Have a first aid kit and clean water nearby for spills.

For uv resin, you also need safety measures:

Wear gloves when handling uncured uv resin.

Protect your work surfaces when using resin.

Ensure adequate ventilation when using uv resin.

Handle the uv resin carefully.

Clean up thoroughly after using uv resin.

Following basic safety habits makes your resin projects enjoyable.

The best resin for clear projects fits your needs. Epoxy resin is good for big, strong things. UV resin works for small, fast details. Use these tips to pick your resin. You will get great, clear results. It is like a crystal floor hardener. It makes a floor surface strong. Both UV resin and epoxy resin can mix with glitter. They can also mix with dye. This makes different looks.

FAQ

What is the main advantage of uv resin?

UV resin cures instantly. This uv resin is perfect for small projects. You get a fast finish. This uv resin helps you finish quickly. This is a great resin.

Can uv resin be used for deep pours?

No, uv resin is not for deep pours. UV light cannot penetrate thick uv resin. This uv resin will not cure. Use epoxy resin for a deep pour finish.

How do I achieve a clear finish with my resin?

Mix your resin carefully. Avoid bubbles for a clear finish. Use high-quality resin. This ensures a beautiful finish. Follow instructions for a perfect finish. This helps your final finish.

See Also

Understanding BANDě Concrete Floor Hardener: Essential Insights for Your Project

Choosing the Best BANDě Floor Hardener for Your 2025 Projects

Upgrade Your Garage: Ditch Epoxy for This Simple Floor Densifier

Selecting a Premium BANDě Crystal Concrete Floor Polishing Service for 2025