Concrete floors endure significant wear, causing dusting and high maintenance. A liquid floor hardener transforms your concrete, enhancing its longevity. This guide helps you choose the best concrete floor hardener for 2025. You will find a hardener for superior durability, cost-effectiveness, and optimal performance. Understanding these liquid hardeners reduces maintenance, improves safety on your floors, and protects your concrete investment.

Key Takeaways

Liquid hardeners make concrete floors stronger. They fill small holes in the concrete. This makes the floor last longer.

Hardened concrete floors are very tough. They do not get damaged easily. This saves money on repairs.

Concrete needs hardening because it can create dust. Hardeners stop this dust. They keep the floor looking good for many years.

Understanding Liquid Concrete Hardeners

What is a Liquid Hardener

A liquid hardener transforms your concrete. These products, often silicate-based, penetrate the concrete’s pores. They start a chemical reaction. This reaction combines the hardener’s components with those already in the concrete. This process forms tighter bonds. It makes the concrete surface denser and harder. Chemical hardeners, rich in silica, react with calcium hydroxide in the concrete. This reaction converts the soft calcium hydroxide into a much harder, denser material. This significantly increases the density of your concrete. It fills excess pores and improves resistance to dirt and stains.

Benefits of Hardened Concrete Floors

Hardened concrete floors offer many advantages. They provide exceptional durability. This safeguards your floors against damage from furniture, pets, and other hazards. Hardened concrete also resists abrasion much better. This means less wear and tear over time. You gain enhanced strength for your concrete. This extends the lifespan of your concrete.

Benefit | Quantifiable Measure |

|---|---|

Durability | Exceptional, safeguarding against damage from furniture, pets, and other hazards |

Why Concrete Needs Hardening

Concrete naturally contains calcium hydroxide. This compound makes the concrete somewhat porous and susceptible to dusting. Over time, traffic and use can cause the concrete to break down. This creates dust and weakens the surface. Applying a liquid floor hardener prevents this. It creates a durable, non-dusting layer. Liquid hardeners are essential for protecting your investment. They ensure your concrete maintains its integrity and appearance for many years. These hardeners improve the overall strength of the concrete.

Hardeners, Densifiers, Sealers: Key Differences

You encounter various treatments for concrete floors. Understanding their differences helps you choose the best one. Liquid hardeners, concrete densifiers, and concrete sealers each serve distinct purposes.

Liquid Hardeners Explained

Liquid hardeners, often called concrete densifiers, are silicate-based materials. You apply them to cured concrete. They penetrate the concrete surface. A chemical reaction then occurs. This reaction produces a byproduct that fills the concrete’s pores. This makes the top layer substantially denser. It enhances durability, abrasion, and chemical resistance. LIQUI-HARD, for example, functions this way. It transforms your concrete into a stronger, more resilient material.

Concrete Densifiers Explained

Concrete densifiers are chemical solutions. They penetrate the concrete. They react with calcium hydroxide, a byproduct of concrete hydration. This reaction forms calcium silicate hydrate (CSH). CSH is a gel-like substance. It fills pores and voids. This increases the concrete’s durability and strength. Densifiers are excellent for polished concrete floors and high-traffic areas. They offer superior hardness and enhanced abrasion resistance. They also provide dust-proofing benefits for your concrete.

Concrete Sealers Explained

Concrete sealers protect the concrete substrate from chemicals. They form a protective film on the surface once cured. This film acts as a barrier. It safeguards the concrete from liquids, stains, and contaminants. Unlike densifiers, sealers offer significant chemical protection. You can find various types, including penetrating, acrylic, epoxy, and polyurethane sealers. Each type has specific properties. You select them based on your intended use and desired outcome.

Choosing the Right Concrete Treatment

You must evaluate your specific needs to choose the right concrete treatment. Consider the floor’s condition first. Assess any existing damage or contamination. Then, think about performance conditions. What chemical exposure will the floor face? How much abrasion will it endure? Will it experience heavy impact or thermal shock? These factors guide your decision. For example, lithium densifiers offer superior hardness for high-traffic areas. Sealers provide chemical resistance. Balance cost with durability for long-term value.

Types of Concrete Floor Hardeners

You have many options when selecting a concrete floor hardener. Each type offers unique chemical bases and applications. Silicate-based densifiers are very common. You will find the right hardener for your specific needs by understanding these differences.

Silicate-Based Hardeners

Silicate-based hardeners are a popular choice for strengthening concrete. These hardeners are aqueous solutions of silicates. They often include a sugar, like saccharose with high purity, to aid in the chemical process. When you apply these solutions, they undergo a series of reactions. First, an ion-exchange reaction occurs between the alkali ions from the water glass and metal ions from the phosphate hardener. This leads to the formation of crystalline alkali phosphate structures. Next, an acid-base reaction happens, causing the pH to drop. Finally, polycondensation of silanol groups to siloxanes forms an amorphous three-dimensional binder framework.

The alkali modulus of water glasses determines the pH value due to the alkaline nature of the M2O content. A decrease in pH reduces the electrochemical stabilization of the sol. This causes silanol groups to condense into siloxanes, forming amorphous three-dimensional frameworks. Boron orthophosphate, as a hardening agent, creates short-chained hydrogen phosphates. It also induces condensation reactions at the network’s periphery. This results in a fast formation of a far-reaching network that prevents free water release. Aluminum phosphate, however, has a higher energy barrier. This leads to condensation in denser network areas. It forms smaller but highly linked domains surrounded by water that can easily leave the samples.

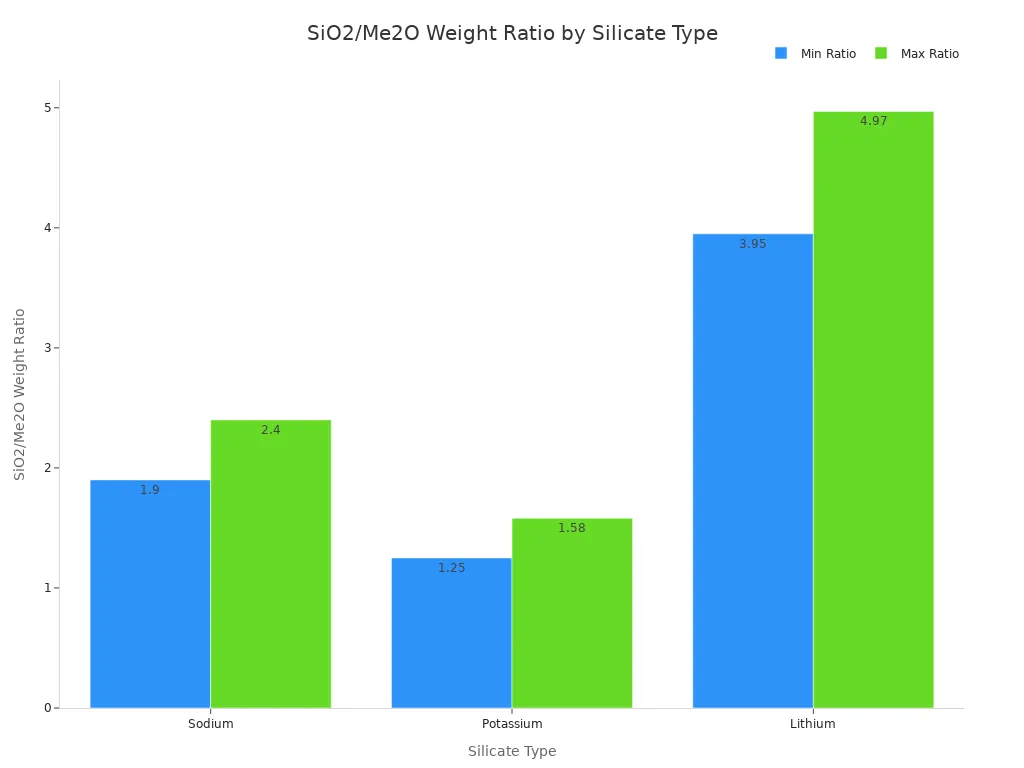

Different silicate types have varying compositions:

Silicate Type | SiO2/Me2O Weight Ratio (Range) |

|---|---|

Sodium | 1.9 to 2.4 |

Potassium | 1.25 to 1.58 |

Lithium | 3.95 to 4.97 |

Lithium Silicate Hardeners

Lithium silicate hardeners are a type of silicate-based hardener. They are known for their smaller molecular size. This allows them to penetrate deeper into the concrete surface. Lithium silicates react with the calcium hydroxide in the concrete. This reaction forms a dense, durable calcium silicate hydrate (CSH) gel. This gel fills the pores, making the concrete stronger and more resistant to abrasion. You often choose lithium silicates for their ability to reduce efflorescence and their excellent performance in polished concrete applications. They provide a superior finish and long-lasting protection.

Sodium Silicate Hardeners

Sodium silicate hardeners are effective for concrete treatment. They penetrate the concrete pores and bind with free lime. This forms calcium silicate hydrate (CSH). This CSH structure narrows the concrete pores, making the top layer denser and harder. This chemical reaction is permanent and irreversible.

Sodium hardeners offer several benefits:

They reduce dust formation and wear of the top layer.

They reduce water and moisture release from concrete due to narrowed pores.

They provide permanent hardening.

However, sodium hardeners have limitations. They cannot create a pearl effect from water or other liquids; this requires water/oil-repellent impregnation. They also cannot prevent the penetration of oil, gas, or chemical products into concrete. Furthermore, they do not prevent freeze/thaw or salt damage, as they do not reduce or prevent water absorption.

You can use sodium silicate hardeners in various applications:

Application Scenario | Performance Characteristics |

|---|---|

Concrete Treatment | Curing compound, surface hardener, enhances strength and chemical resistance, improves durability, reduces water ingress, cost-effective, eco-friendly. |

Industrial Adhesives | Strong binder, especially for cardboard and paper products, enhances bonding strength. |

Sealants | Used for pipe leak repairs and crack filling in concrete structures, improves durability and resistance to chemicals and water. |

Foundry Applications | Binder in sand casting, improves strength and moldability of sand molds. |

Textile and Paper Industry | Protective coating and binder. |

Ceramics and Glass | Provides strength and durability. |

General Use | Adhesive, sealing agent, alkali-resistant, water-reducing, heat-resistant, enhanced durability, cost-effective, versatile, eco-friendly, improved adhesion. |

Potassium Silicate Hardeners

Potassium silicate hardeners are inorganic hardeners. They penetrate concrete and react with calcium hydroxide. This is a byproduct of cement hydration. This reaction generates additional calcium silicate hydrate (C-S-H). C-S-H is the compound responsible for concrete’s natural strength. This process effectively fills internal voids, leading to a denser and tougher surface. These hardeners are well-suited for most industrial environments, including parking lots, warehouses, and workshops.

In the building industry, you primarily use potassium silicate as a concrete densifier. It offers excellent sealing capabilities. It also imparts a good sheen to the surface and provides anti-abrasive properties. Its mechanism involves combining with free limes within the concrete to enhance its strength and seal its pores. Potassium silicates introduce additional silicate into concrete. This silicate reacts with excess calcium hydroxide (free lime), a common cause of micro-pitting. This forms more C-S-H. The creation of additional C-S-H results in denser and harder concrete. This reaction occurs within the capillaries left by water during the curing process. It fills them to provide increased impermeability while still allowing the concrete to breathe and release water vapor.

You will find potassium silicate hardeners useful for:

Floor hardeners and polishers in industrial sheds, corporate buildings, and warehouses.

Reducing dust formation.

Increasing surface durability.

Their non-combustible material properties.

Dry Shake Hardeners

Dry shake hardeners are different from liquid hardeners. You apply them as a dry powder to fresh, newly placed concrete. Workers broadcast the powder evenly over the wet concrete surface. They then float and trowel it into the surface. This process creates a very dense and abrasion-resistant top layer. Dry shake hardeners typically contain cement, finely graded aggregates (like quartz, corundum, or metallic particles), and sometimes pigments for color. You often use them in heavy-duty industrial floors, loading docks, and areas requiring extreme wear resistance.

Integral Hardeners

Integral hardeners are mixed directly into the concrete batch before pouring. Unlike surface-applied hardeners, they strengthen the entire concrete slab, not just the top layer. These hardeners typically consist of finely ground metallic or mineral aggregates. They increase the overall density and compressive strength of the concrete. You choose integral hardeners when you need uniform hardness throughout the slab. This is common in applications where the concrete might be ground or polished deeply, or where you need enhanced durability from top to bottom.

Choosing the Best Liquid Hardener

Traffic Load and Abrasion Needs

You must consider the traffic load your floor will endure. Abrasion resistance is the ability of a surface to withstand deterioration from rubbing, rolling, sliding, cutting, and impact forces. Different applications involve complex combinations like truck and foot traffic or scraping. Premature wear can happen from under-specified or under-strength concrete, or weak surface strength due to construction conditions. Solutions for high abrasion resistance include dry shake surface hardeners, chemical hardeners, and high-performance coatings. The abrasion resistance of a floor depends heavily on the concrete’s composition and the hardness and toughness of the topping material, including finish coatings. Standards such as EN BS 8204-2:2002, ASTM C779, and ASTM C944 guide you on abrasion resistance, performance classes, service conditions, and typical applications. Choosing the right hardener significantly boosts your floor’s durability and strength. This ensures optimal performance for years.

Anticipated Traffic Type | Use | Special Considerations | Final Finish | |

|---|---|---|---|---|

1. Single Course | Exposed Surface – foot traffic | Offices, churches, commercial, institutional, multi-family | Uniform finish, non-slip aggregate in specific areas, curing | Normal steel troweled finish, non-slip finish where required |

1. Single Course–Decorative | Exposed Surface – foot traffic | Decorative concrete | Colored mineral aggregate, color pigment or exposed aggregate, stamped or inlaid patterns, artistic joint layout, curing | As required |

2. Single Course | Covered surface – foot traffic | Offices, churches, commercial, institutional, multi-family with floor covering | Flat and level slabs suitable for applied coverings | Light steel troweled finish |

3. Two course | Exposed or covered surface–foot traffic | Unbonded or bonded topping over base slab for commercial or non-industrial buildings where construction type or schedule dictates | Base Slab – good uniform level surface, curing Unbonded topping– bondbreaker on base slab, min thickness 3 in., reinforced, curing Bonded Topping – properly sized aggregate, ¾ in. min thickness, curing | Base slab – troweled finish under unbonded topping; clean textured surface under bonded topping Topping – for exposed surfaces, normal steel-troweled finish. For covered surface light steel-troweled finish. |

4. Single Course | Exposed or covered surface-foot and light vehicular traffic | Institutional or commercial | Level and flat slab suitable for applied coverings, nonslip aggregate for specific areas, curing. Coordinate joints with applied coverings | Normal steel-troweled finish |

5. Single Course | Exposed surface-industrial vehicular traffic-pneumatic wheels and moderately soft solid wheels | Industrial floors for manufacturing, processing, and warehousing | Good uniform subgrade, joint layout, abrasion resistance, curing | Hard steel-troweled finish |

6. Single Course | Exposed surface-heavy-duty industrial vehicular traffic-hard wheels and heavy wheel loads | Industrial floors subject to heavy traffic; may be subject to impact loads | Good uniform subgrade, joint layout, load transfer, abrasion resistance, curing | Special metallic or mineral aggregate surface hardener; repeated hard steel-troweling |

7. Two course | Exposed surface-heavy-duty industrial vehicular traffic-hard wheels and heavy wheel loads | Bonded two-course floors subject to heavy traffic and impact. | Base slab – good uniform subgrade, reinforcement, joint layout, level surface, curing Topping – composed of well-graded all mineral or all-metallic aggregate. Minimum thickness 3/4 in.; mineral or metallic aggregate surface hardener applied to high-strength plain topping to toughen, curing | Clean, textured base slab surface suitable for subsequent bonded topping. Special power floats for topping are optional, hard steel-troweled finish |

8. Two course | As in Classes 4, 5, or 6 | Unbonded topping-on new or old floors where construction sequence or schedule dictates. | Bondbreaker on base slab, minimum thickness 4 in., abrasion resistance, curing | As in Classes 4, 5 or 6 |

Desired Finish and Aesthetics

The final appearance of your floor is also important. Dry shake hardeners can provide color and surface texture to a concrete floor. You apply them as a dry powder compound to a fresh concrete surface. They can include pigments to achieve desired aesthetic effects. Beyond aesthetics, they also improve hardness and slip resistance. They reduce dusting and liquid penetration. Polished concrete is another option. You achieve it through a multi-step process. This involves mechanical grinding and polishing with diamond tools. Liquid hardeners, also known as densifiers, enhance the hardness and durability of the concrete during this process. The final appearance, including the gloss grade and the level of aggregate exposure, depends on the polishing steps. Each cut further defines the look. A hardener contributes to the overall polished look.

Here are the steps for achieving a polished finish:

Harden the concrete with chemical densifiers or dry shake products.

Remove dirt, grime, or adhesives.

Repair cracks and fill voids.

Grind the hard concrete surface with diamond tooling to expose aggregate.

Polish the concrete floor with higher grit diamond tools to achieve gloss.

Protect, seal, and burnish the floor surface.

Environmental Exposure and Chemical Resistance

Consider the environmental conditions your floor will face. Chemical resistance is crucial in many industrial settings. The final chemical resistance of an epoxy system, for example, depends largely on the hardener you use. Different types offer varying levels of protection.

Amine-based hardeners provide strong adhesion and chemical resistance. They are suitable for industrial coatings.

Polyamide hardeners offer flexibility and chemical resistance. This makes them ideal for coatings in harsh environments like marine or offshore applications.

Phenalkamine hardeners provide excellent resistance to saltwater and corrosion. They are suitable for marine and offshore applications. They are also preferred for tank linings and pipe coatings due to their chemical resistance.

Aliphatic amine-based hardeners provide a high degree of chemical resistance. They are beneficial for chemical-resistant tank lining.

Cycloaliphatic amine-based hardeners offer high chemical resistance. You use them in chemical resistance coatings and flooring.

Aromatic amine-based hardeners provide greater chemical resistance. You mainly use them in tank lining and maintenance coatings in corrosive environments.

Epoxy hardeners are ideal when you need strong chemical resistance. This is especially true in demanding environments like oil & gas or water treatment facilities. You must choose a hardener that protects your investment from specific chemical threats. This ensures lasting performance.

Epoxy Resistance | |

|---|---|

Acetic Acid (20%) | Excellent |

Acetone | Not Recommended |

Acetylene | Excellent |

Alcohol – Ethyl | Excellent (temperature < 120 oF, 50 oC) |

Alcohol – Isopropyl | Excellent |

Alcohol – Methyl | Good (temperature < 71 oF, 22 oC) |

Aluminum Chloride | Excellent (temperature < 71 oF, 22 oC) |

Aluminum Fluoride | Good (temperature < 71 oF, 22 oC) |

Aluminum Hydroxide | Good (temperature < 71 oF, 22 oC) |

Aluminum Sulfate | Excellent (temperature < 71 oF, 22 oC) |

Amines | Excellent (temperature < 71 oF, 22 oC) |

Ammonia – Liquid | Excellent (temperature < 71 oF, 22 oC) |

Ammonia 10% | Excellent (temperature < 71 oF, 22 oC) |

Ammonium Carbonate | Excellent (temperature < 71 oF, 22 oC) |

Ammonium Chloride | Excellent (temperature < 71 oF, 22 oC) |

Ammonium Hydroxide | Excellent (temperature < 71 oF, 22 oC) |

Ammonium Nitrate | Excellent (temperature < 71 oF, 22 oC) |

Ammonium Phosphate | Excellent (temperature < 71 oF, 22 oC) |

Ammonium Sulfate | Excellent (temperature < 71 oF, 22 oC) |

Amyl acetate | Excellent (temperature < 71 oF, 22 oC) |

Aniline | Fair (temperature < 71 oF, 22 oC) |

Barium Carbonate | Excellent (temperature < 71 oF, 22 oC) |

Barium Chloride | Excellent (temperature < 71 oF, 22 oC) |

Barium Hydroxide | Excellent (temperature < 71 oF, 22 oC) |

Barium Sulfate | Fair (temperature < 71 oF, 22 oC) |

Barium Sulfide | Good (temperature < 71 oF, 22 oC) |

Beer | Excellent (temperature < 71 oF, 22 oC) |

Benzol | Excellent (temperature < 71 oF, 22 oC) |

Borax | Excellent (temperature < 71 oF, 22 oC) |

Boric acid | Excellent (temperature < 71 oF, 22 oC) |

Bromine | Not Recommended |

Butadiene gas | Excellent (temperature < 71 oF, 22 oC) |

Butane gas | Excellent (temperature < 71 oF, 22 oC) |

Butyl acetate | Good (temperature < 71 oF, 22 oC) |

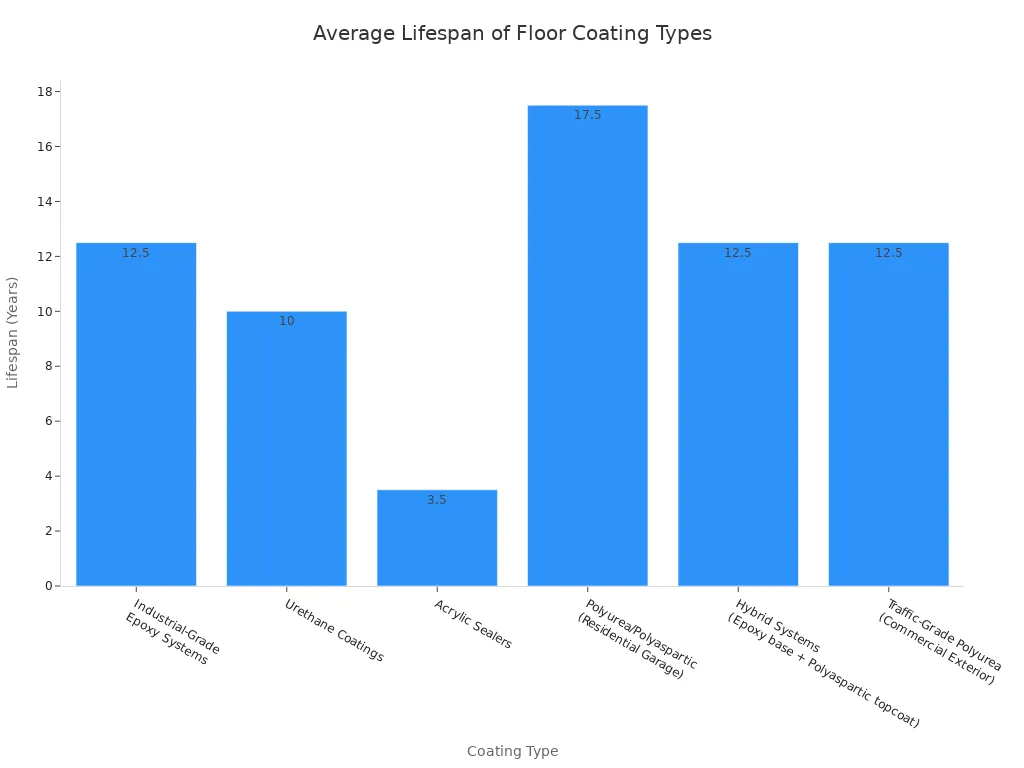

Budget and Long-Term Value

Your budget plays a significant role in your decision. However, consider the long-term value, not just the upfront cost. Liquid floor hardeners are recognized for their ability to enhance concrete surface strength. They reduce maintenance costs and extend the lifespan of infrastructure assets. This positions them as a strategic component in construction procurement decisions, especially with expanding projects. The long-term outlook for the liquid hardeners market is positive. It is driven by an increasing preference for cost-effective and sustainable flooring solutions across various industries. These liquid floor hardeners contribute to sustainability by offering durable and long-lasting flooring. This reduces the need for frequent replacements and maintenance. Investing in a quality concrete floor hardener now can save you substantial money over time. You achieve maximizing your investment by choosing a product that offers superior durability and performance.

Application Feasibility and Curing

Think about how easy the hardener is to apply. Some hardeners require specialized equipment or techniques. Others are simpler to use. Consider the curing and drying times. These times impact your project schedule. A faster curing hardener might be better for projects with tight deadlines. Ensure the application conditions, like temperature and humidity, suit your chosen hardener. Proper application ensures the hardener performs as expected.

Essential Surface Preparation for Concrete

Proper preparation of your concrete floor is crucial before applying any liquid hardener. This step directly impacts the hardener’s effectiveness and the longevity of your floor. Skipping these vital steps can lead to poor adhesion and reduced performance.

Cleaning and Degreasing the Surface

You must thoroughly clean and degrease the concrete surface. This removes contaminants that could hinder the hardener’s penetration. Applying specialized chemicals like Prosoco Cleaner Degreaser, Wax & Cure, Cure & Seal, and Oil & Grease Stain Remover is an effective practice. These cleaners pull contaminants from the substrate, effectively removing high-solid cures and seals, laitance, grease, grime, and oil. This crucial step prevents old coatings and residues from blocking the penetration of subsequent treatments, ensuring optimal application and performance.

Repairing Cracks and Imperfections

Before applying a hardener, you need to repair any cracks, spalls, or other imperfections in the concrete. Use appropriate patching materials to fill these areas. This creates a smooth, uniform surface for the hardener to penetrate evenly. Addressing these issues now prevents them from worsening and compromising the hardened floor’s integrity.

Moisture Testing and Control

Moisture within the concrete can significantly affect hardener adhesion and performance. You must test for moisture before application.

The Plastic Sheet Method (ASTM D4263-05): You tape a 457 x 457-mm plastic sheet to the concrete for at least 24 hours. You then inspect the concrete for darkening or other signs of moisture. This method indicates moisture presence but does not quantify it.

Relative Humidity Test (ASTM F2170-11): You drill holes into the concrete and insert a humidity probe at 40 percent of its total depth. This method provides quantitative results and measures moisture within the middle of the slab, making it more accurate and reliable.

Generally, moisture vapor transmission rates should not exceed 1.3 kg (3 lb)/24 hrs or 75 to 80 percent relative humidity (RH) for most conventional floor primers.

Surface Etching and Profiling

You must profile the concrete surface to ensure optimal hardener adhesion. This creates a texture that allows the hardener to bond effectively. Different techniques achieve various Concrete Surface Profile (CSP) levels:

Acid Etching: This achieves CSP 1, a nearly flat surface.

Grinding: You use rotating discs to achieve CSP 2, a slightly rougher surface.

Shot Blasting: This propels steel beads at high speed to create CSP 3-7 profiles. It is ideal for removing contaminants and adding uniform roughness for mechanical bonding.

Scarifying: This employs rotating blades to reach CSP 4-6, creating deep grooves for industrial coatings.

Choosing the right profiling method ensures the hardener penetrates and bonds properly, maximizing its benefits.

Applying Liquid Floor Hardeners

Tools and Equipment

You need the right tools for effective liquid hardener application. A low-pressure sprayer helps you apply hardeners like LithSeal Lite evenly. This prevents puddling. Use a microfiber applicator to spread any excess hardener. This ensures a smooth, even layer on the concrete surface. For some hardeners, like SpecHard-Intraseal, you might use a mechanical scrubber. This floods the floor and scrubs the hardener into the concrete. Always use a dust vacuum with a shroud. This minimizes airborne dust during concrete grinding. Personal Protective Equipment (PPE) is essential for your safety during the entire application process.

Step-by-Step Application

Applying liquid hardeners involves several key steps. First, ensure you have removed all saw cut debris and dust. Gentle mixing or agitation of the hardener is recommended before you begin. For freshly placed concrete, apply the hardener after final finishing and control joints installation. Use a low-pressure, high-volume sprayer, such as a Chapin 1949 with a 0.5 GPM (1.9 LPM) spray nozzle. Spray in a uniform pattern. Use a microfiber applicator to spread out any puddles. Keep the surface wet for 5–10 minutes. Apply additional material to areas that dry quicker. After 5-10 minutes, remove any excess material left on the surface. Do not allow the hardener to puddle. If you plan subsequent coatings, clean all surfaces beforehand.

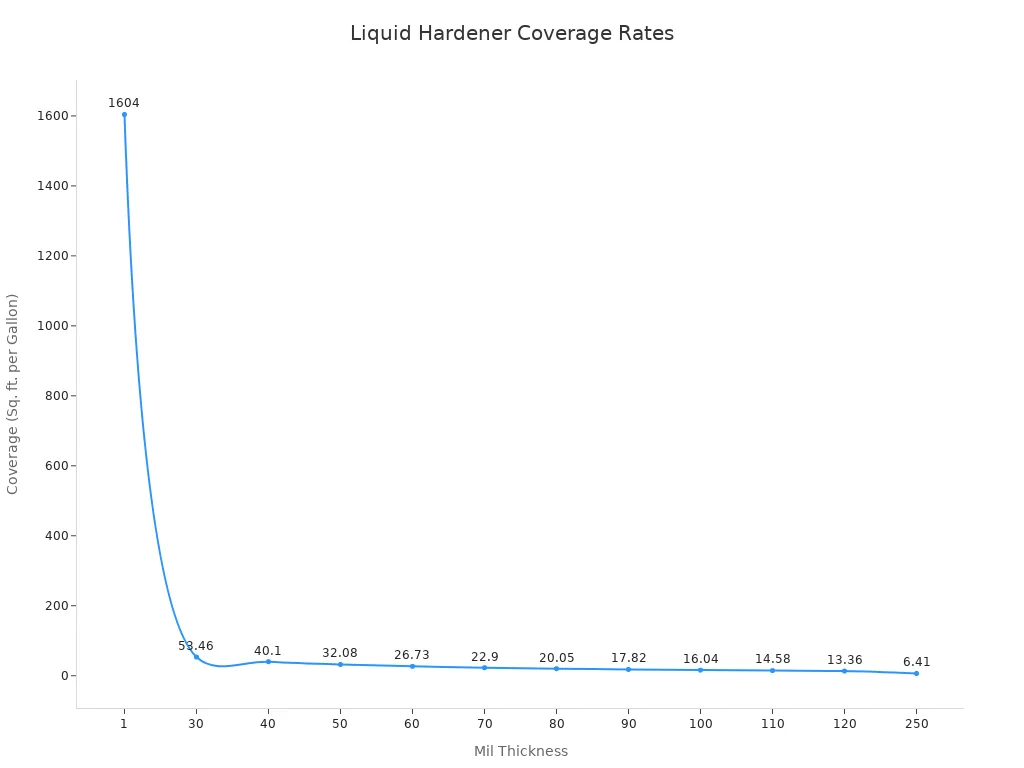

Coverage and Multiple Coats

Coverage rates for liquid hardeners vary. They depend on the concrete’s finish and porosity. For freshly placed, hard-troweled, uncured concrete, expect 800–1000 sq. ft. per gallon. Existing hard-troweled concrete covers 450–800 sq. ft. per gallon. Existing broomed concrete covers 250–400 sq. ft. per gallon.

Type of Surface | ft.2/gal. | m2/L |

|---|---|---|

Freshly placed, hard-troweled, uncured concrete | 800 – 1000 | 19.63 – 24.54 |

Existing hard-troweled concrete | 450 – 800 | 11.04 – 19.63 |

Existing broomed concrete | 250 – 400 | 6.14 – 9.81 |

Always add 10-15% more material to your calculations. This accounts for surface texture, overspray, spills, or equipment issues. VFI generally recommends applying coatings at no less than 30 mils thickness. Always consult the technical data sheet for your specific hardener’s thickness requirements.

Curing and Drying Times

Curing and drying times are crucial for the hardener’s performance. For liquid screed, initial curing takes 24-48 hours. During this time, the concrete should remain undisturbed. Light traffic is acceptable after this period. Avoid full site traffic for 2-3 days. The drying rate for liquid screed is approximately 1mm per day for the first 40mm depth. It is 0.5mm per day for depths exceeding 40mm. These rates assume ideal conditions (20°C and 65% relative humidity). A 40mm thick screed can take about 40 days to dry to 0.5% moisture content. Environmental factors like humidity, temperature, and air changes significantly influence drying times. Higher temperatures and lower humidity can reduce these times. After 7 days, you can reduce drying times by commissioning underfloor heating or using dehumidifiers.

Maintaining Your Hardened Concrete Floor

You have invested in a hardened concrete floor. Now, you must maintain it properly. This ensures its longevity and appearance. Regular care prevents damage and keeps your floor looking new.

Routine Cleaning and Care

You should establish a regular cleaning routine. This protects your hardened concrete.

Daily: Sweep or vacuum your floors daily. This removes dust and dirt. Use a dust mop or a vacuum designed for hard surfaces. This prevents scratches, especially in high-traffic areas.

Weekly or Bi-Weekly: Mop your floor with a microfiber mop. Use a pH-neutral cleaner and warm water. Wring out excess water. This avoids oversaturating the concrete.

For periodic maintenance, consider these steps:

Apply sealants every 1–3 years. This protects polished and stained concrete from moisture and stains. Always follow manufacturer instructions.

Use a polishing machine for polished concrete. This restores shine and removes minor abrasions.

You can use basic cleaning supplies for these tasks:

Category | Items/Description |

|---|---|

Basic Cleaning Supplies | |

Dust Mop/Vacuum | For daily removal of loose dirt and debris. |

Microfiber Mop | Ideal for effective wet cleaning without oversaturating the concrete. |

pH-Neutral Cleaner | Essential for cleaning without damaging the concrete or its sealant. |

Addressing Spills and Stains

Act quickly when spills happen. Prompt action prevents permanent stains. Here is how you can address common issues:

Stain Type | Initial Cleaning Agent/Method | Persistent Stain Treatment |

|---|---|---|

Oil Stains | Degreaser or dish soap, vinegar, washing soda mix | TSP (Trisodium Phosphate) |

Food Grease & Grime | Blot excess grease, laundry detergent & hot water paste | N/A (scrub and rinse) |

Paint Stains | Water mixed with TSP, putty knife to scrape | Paint thinner |

Rust Stains | Lemon juice or vinegar | Commercial rust remover |

Always wear chemical-resistant gloves and safety goggles when using strong cleaners.

Reapplication for Durability

Your hardened concrete floor offers great durability. Over time, heavy traffic or harsh conditions can wear down the protective layer. You might need to reapply the hardener or a sealant. This restores the floor’s protective qualities. Reapplication ensures continued resistance to abrasion and chemicals. It maintains the floor’s appearance and extends its lifespan.

Selecting the right liquid hardener is crucial for your concrete’s long-term performance and investment protection. You gain durability, reduced maintenance, enhanced aesthetics, and improved safety. An informed hardener choice leads to significant cost savings and operational efficiency, offering excellent long-term value. This smart investment reduces future replacement costs. Assess your specific needs carefully, and consult professionals about these hardeners. A well-maintained, hardened concrete floor provides lasting hardener performance in 2025 and beyond.

FAQ

What is the main purpose of a liquid floor hardener?

You apply liquid hardeners to make concrete floors denser and harder. This improves durability and reduces dusting.

Can you apply a liquid hardener to old concrete?

Yes, you can. You must prepare the surface properly. This includes cleaning and repairing any damage before application.

How often do you need to reapply a liquid hardener?

Reapplication depends on traffic and wear. You might need to reapply it periodically to maintain protection and appearance.

See Also

Selecting The Optimal Floor Hardener: A Comprehensive 2025 Comparison Guide

Industrial Floor Hardeners: Your Definitive Comparison Guide For 2025

The 2025 Guide To Choosing Your Perfect Concrete Floor Hardener

Liquid Concrete: Hardener, Sealer, And Densifier For Enhanced Floors

Applying Floor Hardener: Your 2025 Guide For Maximum Concrete Life