Curing agents are essential chemical additives. They initiate a fundamental change in materials. These specialized curing agents convert liquid or pliable substances into solid, durable forms through precise curing. How do these curing agents work, and what makes these curing agents so crucial across various industries? Their transformative power enhances material properties significantly, making the curing process vital. The right curing agent ensures proper curing.

Key Takeaways

Curing agents change liquid materials into strong, solid forms. They start a chemical reaction that makes materials hard and durable.

These agents make materials stronger by linking molecules together. This process helps materials resist heat and chemicals.

Curing agents are important in many industries. They make products like concrete, rubber, and electronics stronger and more reliable.

Understanding Curing Agent Mechanisms

How Curing Agents Initiate Hardening

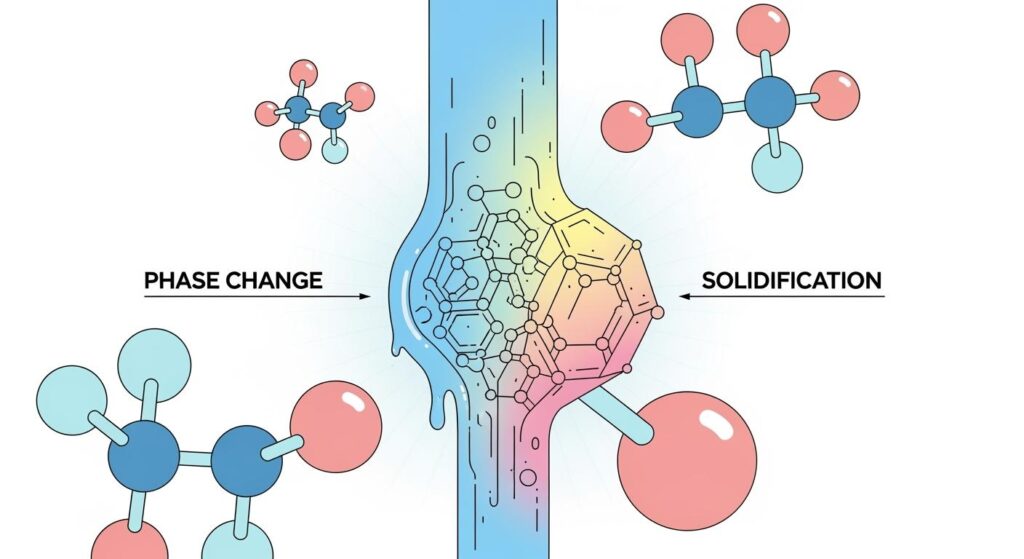

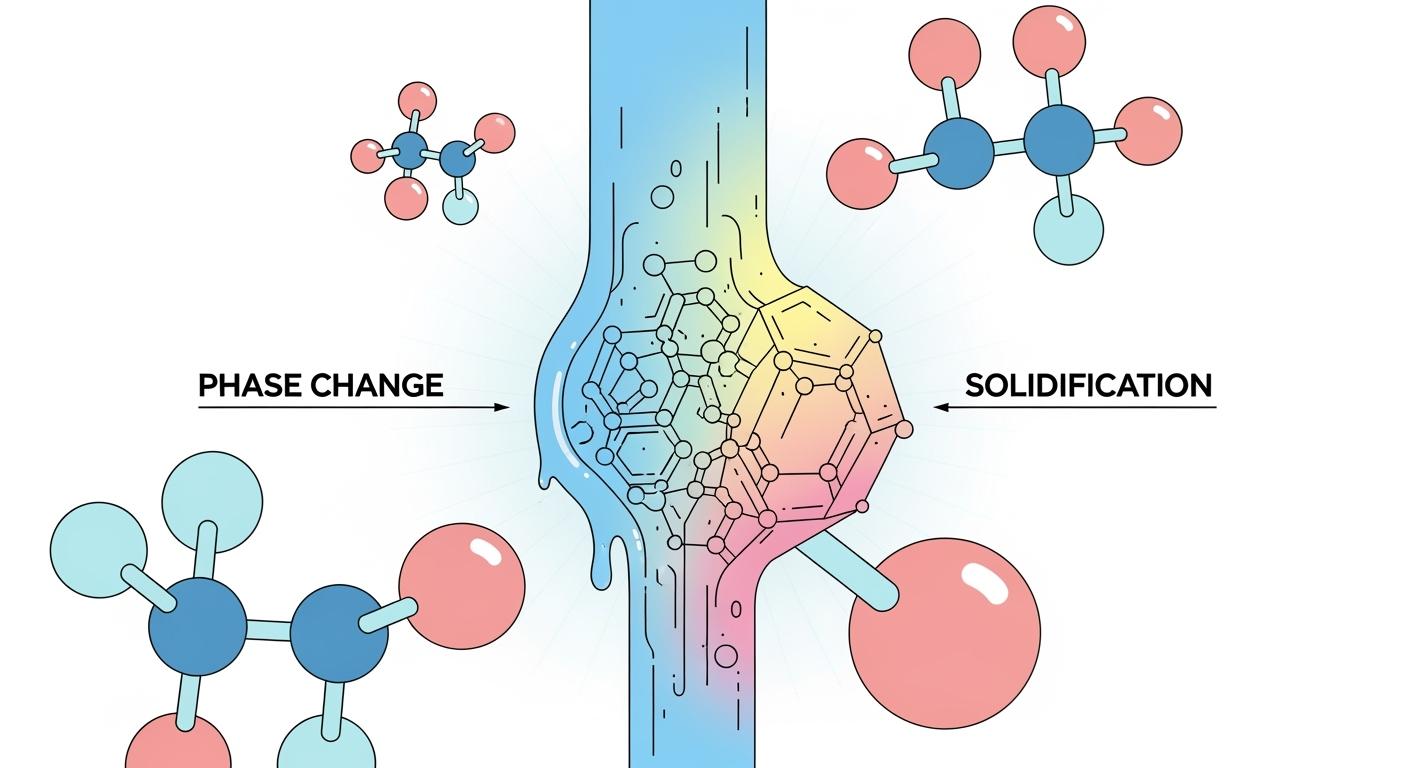

A curing agent starts a chemical reaction. This reaction changes a liquid or pliable substance into a solid. This process is crucial for the hardening of materials. When you introduce a curing agent, it triggers polymerization. Polymerization transforms liquid into a solid, durable finish. For example, hardener paste specifically triggers this polymerization when mixed with polyester-based resins. Fast hardeners contain catalysts. These catalysts accelerate the polymerization process. This rapid hardening makes the material strong and stable. The curing process is essential for many products we use daily. Different curing agents offer unique ways to achieve this transformation. They are truly the unsung heroes of material science.

The Chemistry of Cross-Linking

The magic behind hardening often involves cross-linking. Cross-linking connects long chains of polymer molecules. Metal ions often facilitate this connection. Imagine these polymer chains as long strands of spaghetti. The curing agent acts like a glue. It creates bridges between these strands. This forms a netlike or three-dimensional structure. This cross-linking process makes the material much stronger. It also makes it more resistant to heat and chemicals. Without this cross-linking process, the material would remain weak or liquid. Many curing agents rely on this mechanism. They ensure the final product has excellent durability.

Common Curing Methods Explained

Different curing agents work in various ways. They use different methods to achieve curing. One common method is heat-activated curing. Here, heat provides the energy needed for the chemical reactions. Think about baking an epoxy resin. The heat makes the epoxy harden. Another method uses UV light. UV-cured epoxy systems harden almost instantly when exposed to ultraviolet light. This method is very fast and efficient. It is popular in industries like electronics. Catalyst-driven curing is also widespread. A catalyst speeds up the reaction without being consumed itself. Many epoxy formulations use catalysts. They ensure a controlled and complete curing reaction. For instance, epoxy adhesives often use a catalyst. This allows them to bond strongly. A special type of curing is vulcanization. This process specifically treats rubber. During vulcanization, sulfur acts as a curing agent. It forms cross-links between rubber molecules. This makes the rubber much more elastic and durable. Vulcanization transformed rubber from a sticky substance into a useful materials. Epoxy resins and other products benefit greatly from these diverse curing techniques. Each curing agent and method offers unique advantages. They allow manufacturers to tailor properties for specific applications. We see epoxy everywhere, from floors to aerospace components. Its versatility comes from effective curing. The right curing agent ensures optimal performance for epoxy products. These curing agents are truly transformative.

Curing Agents: Diverse Applications

Curing agents are not just laboratory curiosities; they are workhorses across countless industries. They transform basic substances into high-performance products. These chemical helpers find their way into polymers, resins, adhesives, sealants, and composites. They give these materials the strength and durability needed for everyday use and specialized applications.

Enhancing Material Properties

Curing agents fundamentally change the properties of materials. They increase cohesive strength, improve durability, and enhance bonding. Think about how a liquid resin becomes a strong, rigid part. A curing agent makes this possible. For example, inadequate curing can severely impact a material’s strength, hardness, and elasticity. This happens if there is not enough light or exposure time during the curing process.

Cempatch SBR, a product from BANDě, shows how a curing agent can boost performance. It significantly increases the tensile, flexural, and adhesive strengths of materials. This means the material can withstand more pulling, bending, and sticking forces.

Curing agents are chemical substances that initiate or regulate the hardening process of resins, particularly epoxy resins. When added to epoxy resin, a chemical reaction occurs, transforming the liquid resin into a solid thermoset material. This process involves molecular-level cross-linking, which provides the finished material with mechanical strength, dimensional stability, and crucially, chemical resistance. The selection of the curing agent significantly influences performance attributes such as resistance to chemicals, moisture, and wear.

This cross-linking process is key. It gives the material its robust mechanical strength and dimensional stability. It also provides excellent chemical resistance. The right curing agent ensures the final product can stand up to harsh environmental conditions.

Key Industrial Applications

Many industries rely on curing agents for their products. These applications span a wide range:

Construction (Concrete): Curing agents are vital for concrete. They prevent moisture loss during setting. This helps concrete achieve maximum strength. Chemical sprays and membranes are common. They are widely used in commercial and infrastructure projects.

Rubber Manufacturing (Vulcanization): Curing agents are essential for vulcanization. This process enhances elasticity and wear resistance in products like automotive tires. The rubber manufacturing industry often uses fast-curing agents for quicker production.

Electronics (Encapsulation): Curing agents solidify encapsulants. These protect electronic components from moisture, dust, and stress. This allows for smaller devices and better thermal stability. UV-curing agents are popular for faster processing in this field.

Adhesives and Sealants: These agents create strong bonds and provide environmental resistance. They are used in aerospace, automotive, and construction. Rapid curing adhesives are becoming more common for efficient assembly lines.

Textile and Leather Processing: Curing agents improve water resistance, color fastness, and durability in finishing processes. Eco-friendly solutions are gaining popularity to meet demand for sustainable products.

BANDě utilizes advanced curing agents in their formulations. This allows them to create products with specific properties. For example, their epoxy formulations achieve superior durability and environmental resistance. This makes them suitable for demanding applications in manufacturing and construction.

Curing Agents in Adhesives and Coatings

Curing agents play a particularly critical role in adhesives and coatings. They are the backbone of these products’ performance.

For epoxy coatings, a ‘hardener‘ acts as a curing agent. It reacts with the epoxy resins to create a strong, cross-linked polymer network. This network is essential for the coating’s durability and resistance.

Different types of curing agents offer specific benefits:

Aromatic curing agents: These create rigid, high-strength materials. They offer high heat resistance. This makes them ideal for industrial coatings and structural adhesives. Here, chemical resistance is extremely important.

Water-based curing agents: These are environmentally friendly. They provide effective curing performance. They also contribute to chemical resistance. You find them in applications like flooring, waterproofing chemicals, and construction projects.

Consider Hempadur Mastic paint. This high-solids modified epoxy paint uses polyamide as its curing agent. This helps form a hard, strong coating. It offers protection against corrosion and harsh environmental conditions.

The right curing agent ensures epoxy systems can withstand challenging environments. This includes chemical spills, high humidity, and extreme temperatures. This is vital in industries like oil and gas, marine, and heavy manufacturing. For flooring solutions, the correct curing agent ensures durability and resistance in places like warehouses and hospitals. High-performance curing agents in epoxy adhesives provide strong bonds and resistance to thermal cycling in automotive and electronics manufacturing. Better chemical resistance is a key benefit. It allows products to perform well in their intended environmental settings. These adhesives and sealants are crucial for product integrity.

Curing agents are indispensable in modern material science and manufacturing. They fundamentally transform materials, imparting strength, durability, and specific functionalities through precise curing. This crucial curing process, driven by the right curing agent, ensures product quality. Continuous innovation in advanced curing agents shapes the future of curing agents. These indispensable curing agents drive product performance and industrial advancement in manufacturing, making effective curing paramount.

FAQ

What is the main purpose of a curing agent in materials like epoxy?

A curing agent starts a chemical reaction. This reaction transforms liquid materials into solid, durable forms. It is essential for proper curing of epoxy.

How does a curing agent make epoxy materials stronger during the curing process?

Curing agents create cross-links between polymer molecules. This forms a strong, netlike structure. It enhances the epoxy material’s strength and durability. This process is vital for proper curing.

Are all curing methods the same for epoxy?

No, curing methods vary. Some use heat, others use UV light. Catalysts also drive curing. Different methods suit various epoxy systems and applications. This ensures proper curing.

See Also

Unveiling the Mechanics: How Concrete Surface Hardeners Achieve Their Strength

Densifiers Versus Hardeners: Understanding the Core Distinctions in Concrete Treatment

Your Essential Guide to Selecting Concrete Densifiers, Hardeners, and Sealers

Essential Insights: Understanding the Role of Concrete Bonding Agents Effectively

Cementitious Waterproofing Slurry: Functionality and Application Explained for 2025