Floor hardener is a material used to enhance concrete surfaces, providing numerous benefits. It increases durability, making floors resistant to scratches and stains. Additionally, it dustproofs surfaces, reducing maintenance costs. Applying floor hardener can be simple and rewarding for beginners. By following the method of applying floor hardener, anyone can achieve a professional finish.

Key Takeaways

Thoroughly clean and level the concrete surface before applying floor hardener. This ensures proper adhesion and enhances durability.

Follow the manufacturer’s instructions for mixing and applying the hardener. Accurate mixing ratios are crucial for achieving the desired results.

Use proper troweling techniques and allow adequate curing time to ensure a smooth, professional finish that lasts.

Preparation for Floor Hardener Application

Cleaning the Concrete Surface

Before applying floor hardener, it is crucial to clean the concrete surface thoroughly. A clean surface ensures proper adhesion and enhances the effectiveness of the hardener. Follow these steps for effective cleaning:

Remove Contaminants: Ensure the surface is free from dust, oils, grease, and other contaminants. Common contaminants include:

Frost

Laitance

Surface water

Oil

Grease

Coatings

Loosely adhering particles

Other surface contaminants

Use Appropriate Cleaning Agents: Utilize the right tools and cleaning agents to achieve a spotless surface. Recommended tools include:

Soft Bristle Broom or Dust Mop: Ideal for removing loose dirt and debris.

Microfibre Mop: Effective for cleaning stains and grime.

pH-Neutral Cleaner: Gentle on concrete surfaces.

Degreaser: Essential for removing stubborn oil and grease stains.

Pressure Washer: Useful for outdoor concrete floors.

For instance, a product like Polycote Degrease IT can be applied to the surface, allowed to penetrate, scrubbed, and then thoroughly rinsed to ensure cleanliness.

Dry the Surface: Confirm that the surface is completely dry before proceeding with the application of the hardener. A wet surface can hinder adhesion and lead to poor results.

Leveling the Surface

After cleaning, the next step is to ensure the concrete surface is level. An uneven surface can affect the performance of the floor hardener. Here are the key considerations for leveling:

Check Flatness and Levelness: According to industry standards, the floor should conform to a horizontal plane. The ASTM E1155 standard outlines the protocol for measuring floor flatness (FF) and levelness (FL). Measurements should be taken within 72 hours after concrete placement to ensure accuracy.

Metric | Description |

|---|---|

Floor Levelness (FL) | Measures conformance of a floor surface to a horizontal plane over a 10-foot interval. FL numbers range from FL 15 for general-purpose floors to FL 50 for high-tolerance applications. |

ASTM E1155 | Establishes the protocol for measuring and reporting floor flatness (FF) and levelness (FL) numbers. |

Key Requirements | Minimum sample line lengths of 11 feet for FF measurements and specific patterns for data collection based on floor area. |

Use a Primer: Applying a primer before the hardener can significantly improve adhesion. Primers create a better surface profile for the hardener to bond with, control moisture, and form strong chemical and physical bonds. This leads to enhanced durability and resistance to peeling and blistering.

By following these preparation steps, you will set a solid foundation for the successful application of floor hardener. Proper cleaning and leveling are essential components of the cara aplikasi floor hardener process.

Floor Hardener Application Techniques

Dry Shake Method

The dry shake method is a popular technique for applying floor hardener. This method enhances the surface’s durability and aesthetic appeal. Follow these steps for effective application:

Preparation of the Pouring Area: Ensure the surface is clean and ready for formwork. Use quality concrete and prepare necessary tools.

Pouring Concrete: Pour the concrete when it is at the initial set phase, ensuring it is moist enough to absorb the hardener.

Applying Floor Hardener: Sprinkle the dry shake hardener evenly in two stages, each covering 50% of the area.

Finishing Process: Use a trowel to integrate the hardener with the concrete, ensuring a smooth finish.

Curing: Apply a curing compound for 3-7 days to ensure durability and stability of the surface.

Wet on Wet Method

The wet on wet method involves applying the floor hardener while the concrete is still wet. This technique allows for better bonding and is effective for achieving a uniform finish. Here’s how to execute this method:

Prepare the Surface: Clean the floor thoroughly, removing dirt and debris. Repair any cracks or damage and allow repairs to cure.

Apply the Floor Hardener: Mix the product as per instructions, then apply the slurry evenly using a sprayer or squeegee. Allow the first layer to dry for at least 24 hours before applying additional layers.

Finishing: After the final layer has dried completely, consider applying a sealer for added protection and appearance.

Tools for Application

Using the right tools is essential for a successful application of floor hardener. Below is a table listing the necessary tools and their functions:

Tool | Function |

|---|---|

Mechanical means | Used for cleaning the floor (e.g., shot blasting, diamond grinding) |

Chemical cleaners | Help remove contaminants that prevent bonding with the hardener |

Sprayer or roller | For even application of the hardener at the recommended coverage rate |

Topcoat | Provides additional protection after the hardener has cured |

By mastering these application techniques and utilizing the right tools, you can achieve a professional finish in your cara aplikasi floor hardener project.

Finishing Touches and Curing

Troweling Techniques

Achieving a smooth and durable finish after applying floor hardener requires proper troweling techniques. Follow these steps for effective troweling:

Base Preparation: Clean and level the base, ensuring it is ready for concrete.

Pouring the Concrete: Mix and pour the concrete, leveling it with a screed.

Initial Smoothing: Allow the concrete to set slightly, then smooth it with a hand trowel.

Mechanical Trowelling: Use a power trowel for multiple passes. Adjust the blade angles to achieve a finer finish.

Finishing and Curing: Cut expansion joints and cover the surface to begin curing.

Improper troweling can lead to early damage and complicate maintenance. If not executed correctly, it may result in uneven surfaces, causing aesthetic issues like color differences and varying thickness. These factors ultimately compromise the strength and durability of the floor.

Curing Process

Curing is essential for ensuring the longevity and performance of the floor hardener. Here are some recommended curing methods:

Curing Method | Description | Best For |

|---|---|---|

Water Curing | Keeping the surface continuously wet using techniques like ponding or sprinkling. | Roof slabs, flooring, and columns. |

Membrane Curing | Spraying curing compounds to form a film that locks in moisture. | Large-scale projects and remote areas. |

Steam Curing | Exposing concrete to hot steam to accelerate strength gain. | Precast beams, blocks, and pipes. |

Plastic Sheet Curing | Covering the surface with plastic to prevent moisture loss. | Flat surfaces or vertical walls in hot conditions. |

Internal Curing | Using lightweight aggregates that release water for internal hydration. | High-performance concrete in large structures. |

Proper curing methods help maintain moisture levels, which is crucial for achieving the desired strength and durability of the floor hardener application. Always conduct a final inspection to ensure the surface meets quality standards before use.

Common Mistakes to Avoid

Skipping Surface Preparation

One of the most critical mistakes in applying floor hardener is neglecting surface preparation. Proper bonding of coatings to the substrate is essential for durability. Skipping this step can lead to issues such as peeling, bubbling, or delamination. These problems often result in early failures, increasing repair costs. A well-prepared surface enhances resistance to wear and chemical exposure, contributing to the longevity of the flooring system.

To ensure effective surface preparation, follow these tips:

Thoroughly clean the surface to remove dust, oils, and contaminants.

Repair any cracks or damage before application.

Allow the surface to dry completely to promote proper adhesion.

Incorrect Mixing Ratios

Another common pitfall is using incorrect mixing ratios when preparing the floor hardener. This mistake can disrupt the chemical reaction necessary for proper curing. As a result, the surface may become sticky, brittle, or prone to cracking. Insufficient hardener can lead to blisters, while excessive hardener may create a viscous application that is difficult to smooth out.

To avoid these issues, consider the following best practices:

Follow the manufacturer’s instructions for mixing ratios closely.

Use accurate measuring tools, such as digital scales, to ensure consistency.

Train on proper mixing techniques to prevent costly mistakes.

By avoiding these common mistakes, you can significantly improve the success of your floor hardener application and achieve a durable, professional finish.

Applying floor hardener can be straightforward with practice. Here are the key steps to remember:

Surface Preparation: Clean and level the concrete thoroughly.

Mixing and Application: Follow the manufacturer’s instructions for mixing and apply evenly.

Finishing and Curing: Use proper troweling techniques and allow adequate curing time.

By taking your time and following these steps, you will achieve a durable and professional finish. 🌟

FAQ

What is the best time to apply floor hardener?

The ideal time is during the initial set phase of concrete, typically within 24 hours after pouring.

How long does it take for floor hardener to cure?

Curing usually takes between 3 to 7 days, depending on environmental conditions and the specific product used.

Can I apply floor hardener on existing concrete?

Yes, you can apply it on existing concrete, provided the surface is clean, level, and properly prepared.

See Also

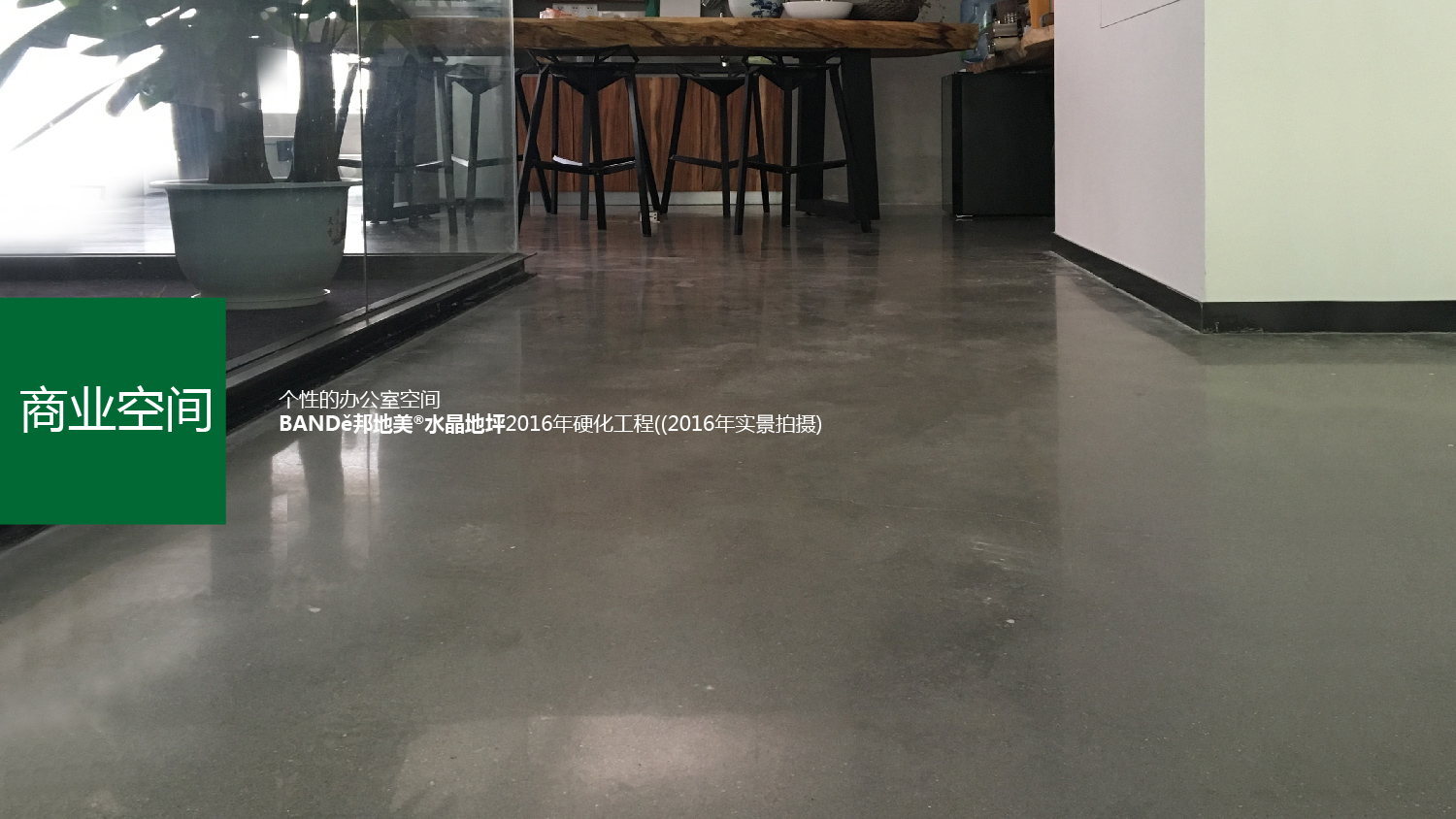

Understanding BANDě Concrete Floor Hardener: Key Insights for You

Floor Hardeners: Their Functionality and Importance Explained

Your Complete Guide to Choosing BANDě Floor Hardeners in 2025