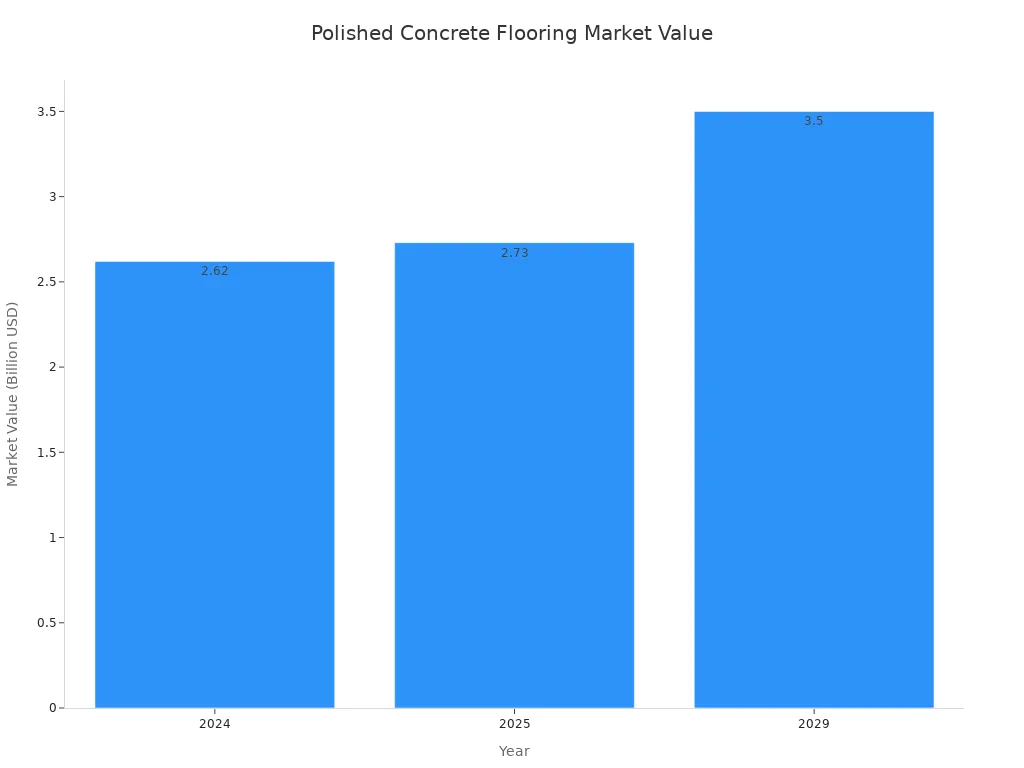

BANDě Polished Concrete offers a premium, durable, and aesthetically versatile flooring solution. It provides a modern appeal and functions as a low-maintenance surface. This type of polished concrete is gaining significant traction. The market for concrete flooring is expanding rapidly, with its value projected to reach $2.73 billion in 2025.

This growing popularity of polished concrete highlights its blend of functionality and style.

Key Takeaways

BANDě Polished Concrete is a strong and beautiful floor. It lasts a long time and looks modern. It is a good choice for homes and businesses.

Making BANDě Polished Concrete involves many steps. Workers grind, harden, and polish the floor. This makes it very smooth and shiny.

This type of floor is easy to clean and good for the environment. It also helps save energy because it reflects light. This makes it a smart choice for any space.

Understanding BANDě Polished Concrete

Defining Polished Concrete

Many people might think polished concrete is just a coating applied to a floor. However, it is actually a mechanical process that transforms an existing concrete slab. This process involves several steps. Workers grind, hone, and polish the concrete surface. They use specialized equipment with diamond abrasives. This reveals the natural beauty and strength of the material.

A crucial part of creating durable polished concrete involves chemical densifiers and hardeners. Workers apply these products to the concrete surface after grinding. These chemicals penetrate the concrete. They react with it to increase its density and shine. This process significantly enhances both durability and appearance. Silicate-based concrete densifiers are fundamental components. They typically contain potassium or sodium silicate compounds with silicon and oxygen. These compounds react with calcium hydroxide, also known as lime, which is present in the concrete. This chemical reaction between silicate ions and calcium hydroxide forms calcium silicate hydrate (CSH) crystals. These crystals fill the concrete’s pores and capillaries. This process, called densification, fills voids, increases density, and enhances hardness. It also improves strength and resistance to abrasion and wear. During the hydration process of concrete, water and powdered cement produce CSH and calcium hydroxide. While CSH acts as the binding agent, calcium hydroxide is a byproduct. Densifiers react with this calcium hydroxide during polishing. This generates more CSH. This greatly increases the hardness and long-term durability of the concrete surface.

Key Characteristics

BANDě Polished Concrete stands out due to several key characteristics. These features make it a top choice for many projects.

Durability: Polished concrete is incredibly tough. Its durability depends on several factors. Concrete with low strength (below 3,000 PSI) lacks the necessary density. This leads to rapid wear. Good aggregate quality and proper gradation ensure a dense, polishable surface. A high water-cement ratio creates a weak, porous surface layer. Densifiers are essential. They react with free lime to create calcium silicate hydrate. This fills pores and hardens the surface, improving wear resistance. Proper curing conditions allow the concrete to achieve its full strength. Improper use of chemical admixtures can weaken the surface.

Aesthetic Appeal: Polished concrete offers a sleek and glossy finish. Grinding, honing, and polishing achieve this look. You can customize it in many ways. Various sheens, stains, patterns, and even logos can be incorporated. The reflective surface also enhances lighting in any space.

Low Maintenance: Once polished, the surface is very easy to clean. It resists dust and allergens.

Eco-Friendly: This flooring solution uses the existing concrete slab. It reduces the need for additional materials. This makes it a sustainable option.

Why Choose BANDě in 2025

Choosing BANDě Polished Concrete in 2025 means selecting a flooring solution that perfectly blends form and function. BANDě utilizes the latest techniques and high-quality densifiers. This ensures maximum hardness and longevity for every project. The extensive customization options allow for unique designs. These designs fit seamlessly into any modern residential or commercial space. BANDě Polished Concrete offers a sustainable, low-maintenance, and visually stunning option. It is a smart investment for anyone looking for a durable and beautiful floor that will last for decades. This makes it a leading choice in today’s market.

Crafting BANDě Polished Concrete in 2025

Crafting BANDě Polished Concrete involves a precise, multi-step mechanical process. This transforms an ordinary concrete slab into a durable, aesthetically pleasing floor. Each stage uses specialized equipment and techniques to ensure a high-quality, long-lasting finish.

Site Preparation

A successful polished concrete project begins long before any grinding starts. Proper site preparation is crucial for optimal adhesion and a flawless finish. First, professionals conduct a thorough assessment and inspection of the existing concrete slab. They visually inspect the surface for defects and perform tap tests with a rebound hammer to check its soundness. They also use ICRI rubber comparators to gauge the current surface profile. Identifying contaminants like oil, grease, dirt, and curing compounds is essential. Adhesion testing after cleaning ensures all contaminants are gone. Workers also examine cracks to understand their extent and cause, measuring widths with comparator cards. Documenting these damages helps select the right repair materials.

Next, preparation techniques begin. Mechanical preparation methods like grinding with abrasive discs or scarifying remove layers and create texture. The choice depends on how much concrete needs removal. Chemical preparation, such as acid etching with muriatic or phosphoric acid, removes contaminants, addresses slight imperfections, and opens the concrete pores. After preparation, thorough cleaning is vital. Workers use brushes, brooms, or industrial vacuums to remove dust and debris. They apply suitable cleaning agents, degreasers, or chemical strippers to remove oil, stains, and sealers. Pressure washing helps with general dirt and tougher grime, with adjusted pressure to prevent damage.

Finally, testing and verification ensure the site is ready. Moisture testing checks for excess moisture using probes or relative humidity meters (ASTM D 4262-83). This ensures the concrete is dry enough for subsequent steps. Pull-off tests (ASTM D4541) determine bond strength. The Concrete Surface Profile (CSP) level guides the preparation. For example, a CSP-1 means a very smooth surface, suitable for thin-film coatings, while a CSP-9 indicates a rough surface, ideal for heavy-duty overlays. The desired aggregate exposure also dictates the depth of preparation:

Depth Required | Visual Impact | |

|---|---|---|

Cream Finish | 1/16″ | Subtle sheen, minimal texture |

Salt & Pepper | 1/8″ | Speckled stone accents |

Full Aggregate | 1/4″ | Dramatic geological reveal |

Grinding the Concrete Surface

Grinding is the foundational step in creating polished concrete. This process uses industrial-grade grinders fitted with diamond abrasives. These abrasives come in different grades, each playing a specific role in shaping the final surface.

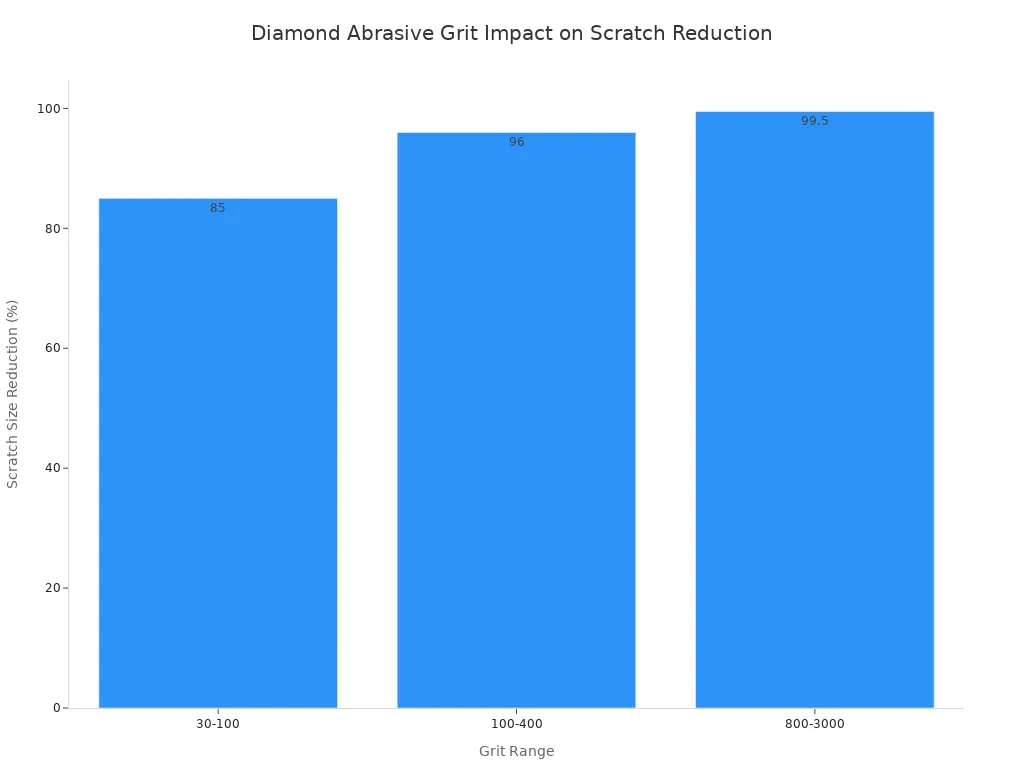

Coarse abrasives, typically 30-100 grit, act like heavy-duty sandpaper. They are primarily for aggressive material removal. These tools strip old sealants, flatten uneven patches, and expose fresh material. They effectively remove deep stains and create a uniform base. Starting with 30-40 grit tools helps level the slab and remove imperfections. Then, 80 grit smooths scratches, and 150 grit refines the surface further.

Medium-grade tools, ranging from 100-400 grit, are crucial for refining textures. They eliminate scratches left from the initial grinding stages and prepare the surface for densification. Skipping this phase can trap imperfections under the glossy finish.

Fine abrasives, from 800-3000 grit, activate chemical reactions that densify the concrete surface. This process creates stain-resistant finishes that repel spills more effectively. Switching to 400+ grit tools helps achieve glossy finishes. Higher grits (800-3000) significantly enhance reflectivity, which is ideal for commercial spaces needing maximum light reflection. Working in circular motions with these fine abrasives helps eliminate micro-scratches and achieve optical clarity.

The impact of these abrasives on scratch size reduction is significant:

Primary Purpose | Scratch Size Reduction | |

|---|---|---|

30-100 | Aggressive material removal | 80-90% |

100-400 | Surface refinement | 95-97% |

800-3000 | Optical clarity enhancement | 99%+ |

The polishing process involves matching diamond abrasives to project needs. Metal-bond diamonds (30-80 grit) are for coating removal and leveling. Resin-bond diamonds (100-400 grit) refine texture and eliminate scratches. Hybrid-bond diamonds (800-3,000 grit) create high-gloss mirror effects. Workers avoid skipping more than two grit levels (e.g., 100 to 400 grit) to prevent micro-scratches. They inspect surfaces with side lighting after each pass. The step-by-step process begins with metal-bond diamonds for sealant removal, using three overlapping passes at 15-degree angles. Vacuuming debris between grit changes prevents contamination.

Hardening and Densifying

After the initial grinding stages, the concrete surface undergoes a crucial hardening and densifying process. This step involves applying liquid chemical hardeners, also known as concrete densifiers. These compounds penetrate the concrete and react with calcium hydroxide (lime), a byproduct of concrete hydration. This reaction forms calcium silicate hydrate (CSH) crystals. CSH is the primary binding agent in concrete. Its formation fills microscopic pores and hairline cracks, significantly increasing the concrete’s density, hardness, and strength. This process can enhance concrete strength and hardness by up to 50%.

The Ashford Formula, a flagship concrete densifier, works this way. It penetrates the concrete surface and reacts with calcium hydroxide to form CSH crystals. These crystals permanently fill the natural pores and voids. This leads to a dense, hard surface resistant to wear, dusting, and chemical damage. This internal and inorganic densification provides long-lasting protection without forming a temporary surface coating.

Various chemical compounds serve as effective densifiers:

Sodium Silicate: This compound penetrates and reacts with concrete to cure, harden, and dust-proof, enhancing durability.

Lithium Silicate: Considered a second-generation product, lithium silicate-based densifiers offer deeper penetration. They create a stronger, more aesthetically pleasing finish. They also hold up well against alkali-silica reactions and provide long-lasting hardening and densification. They offer quick curing, leave no residue, and are environmentally friendly and non-toxic.

Potassium Silicate: Similar to sodium silicates, potassium silicate densifiers are more effective at penetrating concrete. They offer better resistance to chemicals and abrasion, work on new and old concrete, and improve curing time and aesthetic appearance.

Siliconate: This functions similarly to lithium silicates in hardening and densifying floors but has a different chemical composition.

Colloidal Densifiers: Made from nano-sized particles suspended in a liquid, these penetrate deep into concrete. They react with calcium hydroxide, forming CSH. This process fills pores and capillaries, increasing density and reducing porosity for harder, more durable concrete.

Applying densifier typically occurs at the 200-grit stage of grinding. Workers allow it to cure for about 4 hours before continuing the polishing process.

Polishing for Sheen

After densification, the polishing stages begin to achieve the desired sheen. This involves using progressively finer diamond abrasives to smooth the concrete surface and bring out its natural luster. The level of polish determines the final appearance, ranging from a matte finish to a mirror-like shine.

Concrete polishing involves different stages to achieve various sheen levels:

Level 1 (flat): This level stops below 100-grit resin bond. The floor appears hazy with minimal clarity or reflection.

Level 2 (satin): Achieved by stopping at a 400-grit resin bond, this results in a low-sheen finish. A slight overhead reflection is visible from about 100 feet, producing a low-luster matte appearance.

Level 3 (semi-polished): Reached with an 800-grit or higher diamond abrasive, this level offers a significantly higher sheen than Level 2. It provides good light reflectivity. Side and overhead lighting are clearly reflected from 30 to 50 feet.

Level 4 (highly polished): Achieved by using a 3,000-grit resin-bond diamond or high-speed burnishing with specialty pads. This level produces a high degree of shine, allowing for total clarity of reflection when standing directly over the surface. The floor appears wet from various angles.

Here is a breakdown of sheen levels and their corresponding grit ranges:

Level | Grit Range | Sheen Level | Appearance | Gloss Reading |

|---|---|---|---|---|

1 | Below 100 | None to very low | Flat, with little to no reflectivity. | n/a |

2 | 100 to 400 | Low to medium | Satin or matte, with or without slight diffused reflection. | 40-50 |

3 | 800 and higher | Medium to high | Semi-polished; reflected objects are identifiable but not sharp. | 50-60 |

4 | 800 and higher | High | Highly polished; reflected objects are sharp and crisp, mirror-like. | 60-80 |

During this stage, workers switch to resin-bond tools for scratch removal, maintaining consistent machine speed. They finish with hybrid-bond pads in circular motions, adjusting pressure (20 pounds) for slab hardness. Final buffing with wool pads enhances reflectivity.

Sealing and Finishing

The final step in crafting BANDě Polished Concrete is sealing and finishing. This protects the newly polished surface, enhances its durability, and provides additional stain resistance. Various types of sealers offer different benefits and appearances.

Penetrating Sealers: These sealers, made from silicones (silane, siloxane, silicate, silicone), penetrate deep into the surface. They seal access channels to shield against liquid infiltration. They provide invisible protection, allow concrete to breathe, and do not alter the surface appearance or create additional gloss. Foot traffic will not abrade them. They are ideal for outdoor surfaces and industrial facilities that want to avoid frequent applications, though they may need reapplication periodically.

Semi-Penetrating Sealers (Guard Products): These incorporate a topical component, providing vital stain resistance and water repellency. They increase a floor’s surface sheen but wear faster than polyurethane and epoxy. Reapplication depends on foot traffic. They work well for both indoor and outdoor concrete.

Topical Sealers (Polyurethane and Epoxy): These form a protective film on the surface. They repel water, provide durable chemical resistance, and give concrete a high glossy shine. They are durable but require periodic reapplication due to traffic wear. Some may yellow due to UV exposure. They are economical, easy to apply, and best for retail spaces where vibrant color and high sheen are essential.

Urethane Sealers: These are extremely long-lasting, offering superior abrasion and chemical resistance. They provide a glossy or satin finish, making them ideal for high-traffic areas like commercial kitchens or industrial floors susceptible to spills and oil contaminants.

Nano Coating Sealers: These offer superior durability and chemical resistance. They resist staining, abrasion, and impact, and are easy to clean and maintain. They are excellent for industrial spaces, warehouses, domestic areas, and garages.

Specific products offer tailored benefits:

Sealer Type | Stain Resistance Benefits | Longevity Benefits | Recommended Use Cases |

|---|---|---|---|

Ameripolish 3DSPE | Creates a water-resistant barrier, safeguards against stains and etching. | Semi-penetrating and semi-topical. | Light commercial, domestic, and low traffic areas. Creates a gloss finish. |

BOG MODIFIED URETHANE | Guards against stains caused by harsh cleaning chemicals. | Top-notch protection. | Areas prone to liquid spillages like kitchens or workshops that use oils. |

AMERIPOLISH SR2 | Penetrating stain repellent, offers excellent protection by repelling both water and oil. | Solvents give better protection than water-based products. | Best power-floated concrete sealer, good for exposed aggregate concrete. |

Concrete Shield (Nano) | Forms a nanoscale, breathable 3D coating, permanently repels dirt and water, effectively preventing stains and moisture penetration. | Molecular fusion ensures long-lasting protection against weathering, mechanical wear, and chemical abrasion. Wear resistance comparable to concrete itself. | Best sealers for any type of concrete surface, especially smaller domestic jobs where budgets allow. |

Advanced Techniques and Equipment

In 2025, crafting BANDě Polished Concrete benefits from significant advancements in techniques and equipment. These innovations enhance efficiency, quality, and sustainability.

Chemical staining technology has advanced considerably. It enables complex color schemes through acid-based stains, which react with the concrete’s mineral content for variegated appearances. Water-based stains offer more uniform coloration. Modern diamond polishing technology has revolutionized surface quality and consistency. It uses progressive grinding with increasingly fine diamond pads to achieve finishes from satin-smooth to mirror-like. The Concrete Polishing Association categorizes these into four levels, from basic (400 grit) to premium (3000+ grit). Chemical densification, especially with lithium-based densifiers, remains crucial. These densifiers soak deep into concrete to fill tiny gaps, creating a harder, more durable surface that polishes better, resists stains, and extends the lifespan of the polished surface.

The industry also sees a growing adoption of cordless and battery-powered equipment. This offers reduced noise and emissions, improved ergonomics (lighter weight, reduced vibration), and increased mobility on job sites. Examples include the Bosch 18V Profactor Circular Saw, Makita 80V XGT Breaker Hammer, and Hilti 22V Nuron Cut-Off Saw.

Smart and automated systems are becoming standard. They integrate digital technologies for greater precision, control, and data collection. This includes GPS-guided power trowels for uniform finishes, 3D scanners for accurate slab flatness checks, and automated mixing and application systems for colorants, hardeners, or retarders. Ergonomic and lightweight materials are also emphasized. Tools are designed for easier handling and reduced worker strain. This involves using lightweight materials like magnesium and aluminum for tools, incorporating anti-vibration handles, and designing tools with improved balance and comfort, such as adjustable harnesses for vibrating screeds. These advancements ensure BANDě Polished Concrete remains at the forefront of flooring solutions.

Advantages of BANDě Polished Concrete

Durability and Longevity

BANDě Polished Concrete offers exceptional durability and a long lifespan. This flooring option generally outperforms others like vinyl or hardwood, especially in high-traffic areas. Polished concrete resists stains, scratches, and moisture, unlike laminate or carpet. Some flooring options need replacement every 8-12 years, but polished concrete provides long-term savings because it requires minimal repairs and no replacement. Its long-term durability means it can last for decades. For residential use, polished concrete can last 20+ years, even up to 50. Commercial or retail settings see 10-20 years, while industrial warehouses get 5-10 years.

Low Maintenance

Maintaining BANDě Polished Concrete is straightforward. Owners should regularly sweep and occasionally mop with a neutral cleaner. Periodic re-polishing is typically needed only once every few years. Applying a sealer periodically protects against stains and wear. Addressing cracks or chips through concrete repairs helps maintain its look. These concrete floors are relatively low-maintenance and offer long-term cost savings. Basic cleaning supplies are inexpensive. Investing in regular upkeep prevents costly replacements and extensive repairs.

Eco-Friendliness

BANDě Polished Concrete is an environmentally friendly choice. It contributes to LEED certification in several ways. For example, it uses existing concrete slabs and can incorporate recycled content like fly ash or slag from steel production. This reduces the need for new materials. Concrete floors eliminate VOC emissions, prevent allergen accumulation, and improve indoor air quality. Their impressive durability means they can last over 50 years, significantly reducing their environmental impact over time.

Design Versatility

BANDě Polished Concrete offers incredible design versatility. You can customize the sheen level, from a subtle matte to a high-gloss mirror finish. Stains and dyes allow for a wide range of colors, and decorative cuts can create unique patterns. You can also choose the level of aggregate exposure, revealing the natural beauty of the concrete.

Improved Light Reflection

The reflective surface of polished concrete significantly increases natural light within a space. This reduces the need for artificial lighting, leading to energy savings and lower electricity bills. High-gloss polished concrete finishes can reduce lighting needs by up to 30% in commercial settings. This enhanced ambient illumination creates a more pleasant atmosphere and contributes to a reduced carbon footprint. The reflective nature of concrete amplifies light distribution, meaning fewer lights or less energy is needed. This also contributes to the long-term durability of the space.

Considerations and Potential Drawbacks

Even with its many benefits, BANDě Polished Concrete has some things to consider. Understanding these points helps you make an informed decision.

Hardness and Comfort

Polished concrete floors are very hard. This durability is a strength, but it can also be a drawback for comfort. Standing on a hard concrete surface for long periods can increase physical strain. Research shows working on concrete increases tibial shock. This is like adding an extra 12 pounds of strain. Employees might feel more pain and get injuries. Health problems like bunions, shin splints, and lower back pain are common. Employers can help by using softer flooring or providing anti-fatigue mats.

Temperature Properties

Concrete has high thermal mass. This means it absorbs, stores, and releases heat. This property helps regulate indoor temperatures. It keeps spaces cooler in summer and warmer in winter. This can save energy and lower utility bills. However, without proper insulation, the floor can feel cold to the touch in cooler climates. Dense concrete surfaces absorb daytime heat. They release it slowly at night. This stabilizes indoor conditions. High-gloss surfaces reflect light. This reduces heat retention in rooms by 40-60%.

Cracking and Moisture

Polished concrete is stain-resistant, but it is not stain-proof. Substances like wine, lemon juice, vinegar, and oils will not immediately damage the surface. However, you should not leave them on the floor overnight. Cracking can also occur in concrete. Poor concrete mix design or inadequate curing methods can cause this. Extreme temperatures and improper installation also contribute. Using reinforcement like rebar or fibers helps prevent cracks. Regular inspections and maintenance are also important.

Acoustics

Hard surfaces like polished concrete reflect sound waves. This can lead to increased echo and reverberation. Large, open spaces with polished concrete floors might become noisy. Conversations can be hard to hear. You can manage this with rugs and soft furnishings. Acoustic panels on walls or ceilings also help. Textured concrete finishes can scatter sound waves. Plants can also absorb and scatter sound.

Installation Complexity

Installing polished concrete requires specialized skills and equipment. Workers need to assess the surface carefully. They use tools like industrial diamond abrasives and densifiers. The installation process involves many steps. The size and shape of the floor affect the timeline. A higher gloss finish takes more time. The existing condition of the concrete surface also impacts the installation duration. Complex architectural features can extend the project.

Cost and Value in 2025

Factors Influencing Costs

Several factors influence the cost of BANDě Polished Concrete. The project type, whether commercial or residential, plays a big role. For example, commercial projects in the Tri-State area often cost $3 to $12 per square foot, with most basic jobs falling between $5 and $8. Residential projects in the same area typically range from $5 to $18+, with quality work usually costing $8 to $12. The finish level also matters. Basic polishing might be $3 to $7 per square foot, while premium finishes can reach $12 to $18+. The desired sheen level also affects pricing. A low sheen (Level 1) might be $3 to $5, but an ultra-high gloss (Level 4) can be $12 to $18+. If the existing concrete needs repairs, expect an additional $2 to $8 per square foot. Labor costs in metropolitan areas, like New York City, are generally higher.

Long-Term Value

Polished concrete floors are a smart investment. They offer significant long-term savings. These floors are designed to last decades with minimal upkeep, often exceeding 20 years with proper maintenance. This contrasts sharply with materials like carpet or vinyl, which can peel or warp. The grinding and polishing process strengthens the surface. This makes it resistant to heavy foot traffic, spills, and abrasions. This durability means fewer costly repairs or early replacements.

Initial vs. Lifecycle Costs

Consider the initial cost versus the total cost over the floor’s life. For 20 years of use, VCT (Vinyl Composition Tile) flooring can cost about $15 to $20 per square foot. Polished concrete, however, lasts much longer. Its lifespan is typically 20 to 30 years, while commercial luxury vinyl might last up to 20 years. Maintenance for polished concrete is simple. It only needs occasional sweeping and mopping. This eliminates the need for waxing or harsh chemical cleaners. This low-maintenance aspect, plus energy savings from light reflection, contributes to a lower total cost of ownership. Over time, polished concrete saves thousands of dollars in replacement costs, cleaning, and energy bills.

Market Pricing Trends

The market for polished concrete continues to grow. Basic polish finishes typically cost $3 to $5 per square foot. Mid-level finishes are $5 to $8, and high-end custom work can be $8 to $15+. If slabs are damaged, repairs might add $1 to $3 per square foot. For residential projects, a “cream” finish might be $3.50 to $6.00. A “salt and pepper” finish starts from $4.00, but for large commercial jobs, it can be as low as $1.00. Adding a gloss finish costs $0.40 to $0.75 more per square foot, and concrete dye adds $1.00 to $2.00 per square foot.

Comparing BANDě Polished Concrete Floors

When choosing flooring, many options exist. BANDě Polished Concrete stands out. Let’s see how it compares to other popular choices.

Polished Concrete vs. Epoxy

Both polished concrete and epoxy flooring create durable surfaces. They have key differences, though. Epoxy flooring often needs recoating every 5 to 10 years. Polished concrete floors can last over 20 years. They only need resealing every 2 to 3 years. Maintenance for polished concrete is generally easier. Epoxy requires more upkeep. It is sensitive to certain chemicals. Lifetime costs for polished concrete are typically lower. This is because of less frequent major work. A well-polished concrete floor can last more than 15 years before major refinishing. It only needs basic cleaning and occasional buffing.

Feature | Polished Concrete | Epoxy Flooring |

|---|---|---|

Long-Term Durability | 20+ years | 5-10 years (recoating needed) |

Maintenance Frequency | Resealing every 2-3 years | Recoating every 5-10 years |

Maintenance Difficulty | Easiest | More upkeep (avoid chemicals) |

Lifetime Costs | Lower | Higher (due to recoating) |

Wear Resistance | Good (but shorter ‘short-term durability’) |

Polished Concrete vs. Hardwood

Hardwood floors offer warmth and classic beauty. Polished concrete provides a modern, industrial look. Hardwood scratches easily. It also needs special care for spills. Polished concrete resists scratches and moisture well. Hardwood requires more maintenance. It needs refinishing every few years. Polished concrete is much simpler to care for.

Polished Concrete vs. Tile

Tile floors come in many styles. They can be durable. However, grout lines are a common issue. Grout can stain and collect dirt. This makes cleaning harder. Polished concrete offers a seamless surface. It has no grout lines. This makes concrete floors much easier to clean. They also look sleek and continuous.

Polished Concrete vs. Vinyl

Vinyl flooring is affordable and versatile. It can mimic other materials. However, vinyl has a shorter lifespan than polished concrete. It can also dent or tear. Polished concrete is extremely durable. It lasts for decades. It is also a more eco-friendly option.

Care for Your BANDě Polished Concrete Floor

Maintaining your BANDě polished concrete floor ensures its lasting beauty and durability. A simple routine keeps the surface looking great.

Routine Cleaning

Keeping your BANDě polished concrete clean is straightforward. Daily dusting with a microfiber mop effectively removes abrasive particles. This prevents scratches on the surface. For weekly wet mopping, use a pH-neutral cleaner. This preserves the finish of your polished concrete. Avoid harsh chemicals, as they can dull the shine. Every few months, perform a deep clean. An auto-scrubber with a non-abrasive pad can revive the floor’s luster. Always use clean water and mops for the best results.

Addressing Spills

Accidents happen, but quick action prevents stains on your polished concrete floor. For oil-based spills like cooking oil, blot the excess immediately. Then, cover the stain with an absorbent material such as cat litter or baking soda. Scrub with a pH-neutral degreaser. Acid-based spills, such as vinegar or citrus juice, need immediate neutralization. Rinse the area with plenty of water and apply an alkaline cleaner. For organic stains like coffee or wine, use a mild detergent. Always test cleaners in a hidden spot first to ensure they do not damage the surface.

Periodic Re-Sealing

Even with its inherent durability, periodic re-sealing helps maintain the protective qualities of your BANDě concrete. This step enhances stain resistance and preserves the floor’s luster. The frequency of re-sealing depends on the amount of traffic and wear the floor experiences. Re-sealing ensures your floor continues to look its best for many years.

Design Styles and Customization

BANDě Polished Concrete offers many design possibilities. You can truly make your floor unique. These options allow for a personalized look that fits any space.

Sheen Levels

You can choose from various sheen levels for your polished concrete floor. Each level creates a different aesthetic. Matte finishes offer minimal light reflection, giving a natural look. Satin finishes provide a soft glow with moderate reflectivity. High-gloss finishes deliver a mirror-like shine. This is ideal for spaces needing brightness and sleek aesthetics.

Level | Grit Range | Finish Type | Best For |

|---|---|---|---|

1 | Below 100 | Flat | Warehouses, garages |

2 | 400 | Satin | Homes, lobbies |

3 | 800+ | Semi-Polished | Stores, offices |

4 | 3000 | Mirror | Galleries, luxury spaces |

Color Staining and Dyeing

Color can dramatically change your concrete floor. For polished concrete, workers apply stains before the densifier. This ensures proper absorption and deep penetration. Applying stain after hardening begins can result in an uneven final color. Concrete dyes offer vibrant colors. They are often used on polished concrete floors. Dyes penetrate easily due to their small particle size. While concrete dyes generally do not hold up well under ultraviolet light, some products include UV buffers. These help retain true and bright colors.

Decorative Cuts

Decorative saw cuts add unique patterns to your floor. To avoid degrading the finish, workers make these cuts before grinding and polishing. This technique allows for custom designs and borders.

Aggregate Exposure

You can also choose how much aggregate shows through. This reveals the natural beauty of the concrete.

Technique | Grinding Depth | Aggregate Exposure | Design Effect |

|---|---|---|---|

Cream Polished (Surface Cream) | 1/32 – 1/64 inch | Minimal, top layer of cement paste | Consistent color, fewer imperfections, versatile for staining |

Salt and Pepper | 1/64 – 1/8 inch | Fine aggregate (sand and tiny stones) sporadically revealed | Distinctive ‘salt and pepper’ appearance |

Exposed Aggregate | 1/8 – 1/4 inch | Coarse aggregate (small, medium, or large) | Reveals the full texture and color of the coarse aggregate |

Polished concrete with exposed aggregate offers great versatility. You can customize it with materials like recycled glass or seashells. This complements any decor.

BANDě Polished Concrete offers unmatched durability, stunning aesthetics, and sustainability. This leading flooring choice for 2025 provides long-term value and modern appeal. Consider this polished concrete for your next project. Its durability and innovative crafting define the future of concrete flooring.

FAQ

Is BANDě Polished Concrete slippery?

Polished concrete is not inherently slippery. Its slip resistance is similar to regular concrete. Sealers can add extra grip.

Does BANDě Polished Concrete crack easily?

Properly installed and cured BANDě Polished Concrete resists cracking. However, concrete can crack due to ground movement or improper installation.

Can I use BANDě Polished Concrete outdoors?

Yes, you can use BANDě Polished Concrete outdoors. It offers durability and weather resistance. However, it may require specific sealers for outdoor conditions.

See Also

Choosing Premier Crystal Concrete Floor Polishing Services with BANDě for 2025

Essential Guide to BANDě Concrete Densifiers and Hardeners in 2025

Selecting the Best BANDě Concrete Sealer: An Ultimate 2025 Guide

Understanding BANDě Concrete Densifier: A Comprehensive Operational Guide

Exploring BANDě Concrete Densifiers: Definition and Functional Mechanisms Explained