A Polished Concrete Densifier fundamentally enhances your polished concrete surface. These densifiers strengthen the concrete surface, crucial for longevity and performance. Densifiers also boost aesthetic appeal. BANDě, an expert in concrete surface solutions, understands densifiers. Choosing the right densifier ensures optimal results in 2025. The growing concrete chemicals market demands effective densifiers.

Key Takeaways

Concrete densifiers make your polished concrete floors stronger and last longer. They fill tiny holes in the concrete, making it harder and more resistant to damage.

Different densifiers work best for different needs. Consider how much traffic your floor gets and the look you want. This helps you pick the right type of densifier.

Proper preparation and application are important for densifiers to work well. Clean your concrete surface first. Then, apply the densifier carefully to get the best results.

What is a Polished Concrete Densifier?

Densifier Basics for Polished Concrete

A polished concrete densifier is a chemical solution. You apply this solution to concrete to increase its density and hardness. These densifiers react with components inside your concrete. Alkali silicate densifiers react with calcium ions in the concrete’s surface layer. This reaction forms an inorganic gel. This insoluble silicate gel acts as a micro-filler. It creates a compact and dense microstructure on the treated concrete surface. Silica-based concrete densifiers contain nano-sized silica particles. These particles react with free lime (calcium hydroxide). This is a byproduct of cement hydration. This reaction forms additional calcium silicate hydrate (CSH). CSH increases the density of the cement paste. It fills open voids. This enhances the concrete’s overall strength. Densifiers react with free lime or calcium hydroxide within the concrete matrix. This creates CSH crystals in the concrete’s pores and capillaries.

Why Polished Concrete Needs Densification

Your polished concrete needs densification for several reasons. Concrete naturally has pores. These pores make the surface susceptible to damage. Without densification, polished concrete experiences chipping and cracking. It also suffers from a loss of surface strength. Dusting becomes a problem. Water penetration and wear also occur. Densifiers fill these pores. They create a much harder and more durable surface. This process makes the concrete less permeable. It resists stains better. This also makes the surface easier to clean and maintain. Ultimately, densifiers extend the life and improve the appearance of your floor.

Benefits of Concrete Densifiers

Enhanced Hardness and Wear Resistance

You gain significant advantages when you apply concrete densifiers to your floors. One major benefit is enhanced hardness. Densifiers give concrete a tougher surface, leading to improved hardness that prevents signs of wear even under demanding conditions like heavy foot traffic and machines. For example, densified concrete often shows a surface hardness of 6–7 on the Mohs scale, compared to 4–5 for untreated concrete. This translates to an increase in abrasion resistance by up to 35–40%. This improved durability means your polished floors will withstand daily abuse much better.

Improved Impermeability and Stain Resistance

Another key advantage, among the many benefits of using a densifier, is improved impermeability. Densifiers fill the microscopic pores in your concrete. This makes the surface much less porous. As a result, liquids cannot easily penetrate the concrete. This leads to better stain resistance against spills like oil, chemicals, or food. You will find your polished floors stay cleaner and look better for longer.

Dust Proofing and Easier Maintenance

You will also appreciate the dust-proofing capabilities. Untreated concrete often releases fine dust particles, including laitance, a weak surface layer. Concrete densifiers mitigate dust release by creating a denser surface. They fill the micropores within the concrete, which significantly reduces dusting. This process minimizes the release of dust particles, thereby improving indoor air quality. Silicate densifiers are especially effective. They eliminate excess calcium hydroxide, which contributes to chalky deposits. These benefits make cleaning your polished concrete floors much easier and reduce maintenance efforts. These are clear benefits of using a densifier.

Types of Concrete Densifiers

You have several options when choosing types of concrete densifiers. Each type offers unique properties. Understanding these differences helps you select the best product for your project.

Lithium Silicate Densifiers

Lithium silicate densifiers are often considered a more advanced option among the types of silicate densifiers. They penetrate concrete deeply. They react efficiently with calcium hydroxide. This forms a dense, hard surface. You will find they cause less surface whitening compared to other silicates. They also offer excellent abrasion resistance. These densifiers are a popular choice for polished concrete.

Sodium Silicate Densifiers

You encounter sodium silicate densifiers as the oldest and most affordable option among the types of silicate densifiers. However, they present some challenges:

Sodium silicates can elevate the concrete’s pH. This potentially causes surface whitening.

Their ability to raise pH links to Alkali-Silica Reaction (ASR) in certain conditions. ASR leads to cracking.

They often react too quickly on the surface. This prevents full penetration.

Inadequate byproduct removal results in stubborn white residue.

You need to pre-dampen the surface. You also need to scrub the sealer. Multiple applications are usually necessary.

Potassium Silicate Densifiers

Potassium silicate densifiers represent an attempt to improve upon sodium silicates. These types of silicate densifiers offer some advantages.

Property/Characteristic | Potassium Silicate Densifiers | Sodium Silicate Densifiers |

|---|---|---|

Molecular Structure | Slightly smaller | Larger |

Penetration Depth | Deeper | Less deep |

Cost | More expensive | Less expensive |

Surface Whitening | Lessened, but not eliminated | More prevalent |

Potassium silicates still require dampening, scrubbing, and rinsing. They can also raise concrete pH. They contribute to ASR. They enhance material properties. They improve durability and water resistance. Their eco-friendly profile makes them a preferred choice.

Colloidal Silica Densifiers

Colloidal silica densifiers offer a different approach. They primarily use hydrogen bonding. This creates a weaker bond compared to covalent chemical bonds. They have limited interaction with calcium hydroxide. They do not form strong C-S-H. Their long-term stability may break down under moisture. They offer shallow densification depth. Their particle size is typically larger. However, colloidal silica concrete densifiers improve workability of wet concrete. They help control moisture loss. This minimizes shrinkage. They act as a lubrication aid during troweling. They increase the workability window. They reduce tool wear. They enhance resistance to shrinkage cracking. They minimize curling. They improve freeze-thaw durability. They prevent crazing. These concrete densifiers make concrete harder. They cure the entire slab better. They slow moisture loss. They reduce curling. They impart hydrophobic properties. They reduce dusting. They benefit floors with wheeled traffic. They lower permeability for pavements.

How to Choose the Right Densifier

You need to select the right densifier for your project. This choice impacts the longevity and appearance of your concrete. Consider several factors to choose the right densifier.

Project Needs and Traffic Levels

Your project’s specific needs and expected traffic levels guide your densifier choice. Different environments demand different levels of durability. For example, a busy warehouse floor faces much more wear than a quiet residential basement.

You can see recommended densifier types based on environment:

Environment Type | Recommended Densifier | Key Characteristics |

|---|---|---|

High-Traffic Commercial | Sodium Silicate | Deep penetration, high wear resistance, matte finish, suitable for industrial use |

High-Traffic Commercial (Heavy Foot/Forklift) | Sodium or Potassium Silicate | Deeper penetration, better wear resistance |

Commercial (Showrooms/Lobbies) | Lithium Silicate | High sheen |

Low-Traffic Residential | Potassium Silicate | Balanced penetration, moderate shine, faster drying, durable without high-gloss |

For high-traffic commercial areas, you often need densifiers that offer maximum wear resistance. Sodium silicate densifiers provide deep penetration and a durable surface. For residential spaces with less traffic, potassium silicate densifiers offer a good balance of durability and aesthetic appeal. You must match the densifier to the expected use of your polished floors.

Desired Finish and Aesthetic Goals

The final look of your concrete surface also influences your choice. Do you want a high-gloss, a satin, or a matte polished finish? Different densifiers can contribute to these varied aesthetic goals. Lithium silicates often help achieve a higher sheen. Sodium silicates typically result in a more matte appearance. Potassium silicates offer a balanced shine. You should consider how the densifier interacts with your polishing process to achieve the desired visual effect. The right densifier enhances the beauty of your concrete.

Budget and Environmental Factors

Your budget plays a role in selecting densifiers. You will find variations in cost among different types.

Lithium and potassium silicates generally cost more per gallon than sodium silicates.

However, when you apply them at manufacturer-suggested rates, lithium and potassium silicates often have a comparable price per square foot to sodium silicates.

For example, a SiO2 densifier like ‘Polished Concrete Densifier – Rockhard PCD’ costs about $0.38 to $0.50 per square foot. It covers 300-400 square feet per gallon. You need to balance cost with performance and environmental impact.

Consider the environmental footprint of the product. Many modern densifiers are formulated to be eco-friendly. This includes being water-based and having low volatile organic compound (VOC) content. Choosing environmentally responsible products helps protect both the planet and indoor air quality.

Specific Product Attributes (Colorless, Non-toxic)

You should look for specific product attributes to ensure safety and quality. A colorless densifier will not alter the natural color of your concrete. Non-toxic formulations are crucial, especially for indoor applications. These attributes contribute to a safer environment.

Low-VOC products are very important for indoor air quality.

Purchasing low-VOC versions of products helps reduce the quantity of volatile organic compounds (VOCs) in indoor environments.

This reduction specifically targets dangerous VOCs such as benzene, formaldehyde, and methylene chloride, contributing to safer indoor air.

Many national and international programs certify products based on their indoor air quality impacts. These impacts include odor, irritation, chronic toxicity, or carcinogenicity. However, norms for product labeling and certification are not always standardized. This makes it difficult to understand labels like ‘low-VOC’ or ‘zero VOC’. Some labels focus on VOCs emitted into the indoor environment. Others base their claims on VOC content regulated for outdoor photochemical smog. This may not fully assess all relevant indoor air quality concerns.

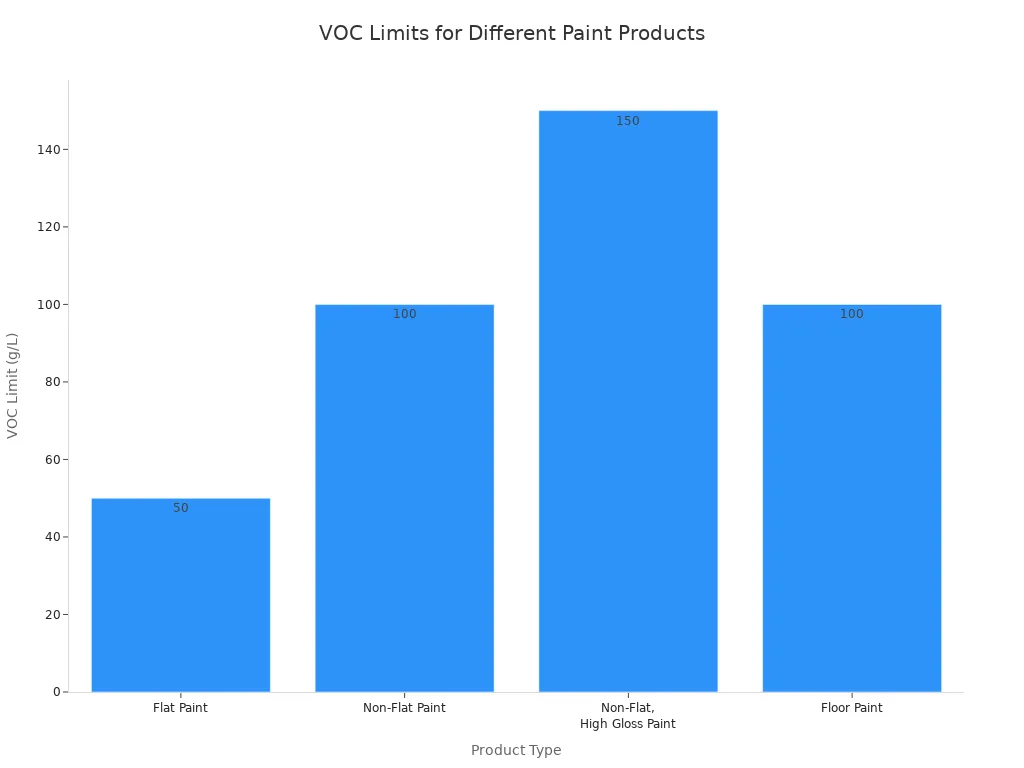

You can refer to typical VOC limits for various paint products:

Product | VOC Limit (g/L) |

|---|---|

Flat Paint | 50 |

Non-Flat Paint | 100 |

Non-Flat, High Gloss Paint | 150 |

Floor Paint | 100 |

Products labeled as ‘VOC-free’ or ‘low-VOC’ are available. They are important for mitigating indoor air quality issues. These issues come from chemicals evaporating from paints, varnishes, adhesives, and cleaners. While ‘low-VOC’ lacks a standardized definition, the general aim is to reduce these compounds. You should choose the right densifier that prioritizes health and safety.

Applying Your Concrete Densifier

Essential Surface Preparation

Before you apply any concrete densifier, proper surface preparation is crucial. You must ensure the concrete surface is clean, dry, and free from all contaminants like dirt, grease, sealers, or curing compounds. You can achieve this through grinding, shot blasting, or thorough cleaning. A well-prepared surface allows the densifier to penetrate effectively and react properly.

Best Application Techniques

You should follow specific best practices for applying densifiers. For products like E57936 Lithium Concrete Densifier, you can use spraying or mopping. Ensure you saturate the surface without creating puddles. Coverage rates vary; expect 100 to 400 square feet per gallon, depending on how absorbent your concrete is. For potassium silicate hardeners, you flood the surface and scrub the solution into the concrete. Colloidal silicas apply with a sprayer and a microfiber applicator, similar to lithium silicates. A general principle is to flood the floor with silicate for at least 30 minutes, or until the concrete will not accept any more material. Recommended coverage is 400-500 square feet per gallon on normal concrete. Applying at 800-1,000 square feet per gallon is insufficient. For existing concrete, use an industrial sprayer or lint-free mop, ensuring saturation for 30-60 minutes. Rework excess material with a soft bristle broom. For polished concrete, apply a uniform coat after the 400-grit stage. Typically, one coat at 200-300 sq ft per gallon is sufficient, but softer floors might need two coats. These techniques ensure the densifiers work effectively.

Common Application Mistakes to Avoid

You must avoid common mistakes to ensure optimal results from your concrete densifier. One error is not understanding the concrete’s porosity, which leads to uneven application. Another mistake is rushing the application or removal process, not allowing the densifiers enough time to react. Applying densifiers to a surface with existing flaws or poor preparation can also cause issues. This leads to uneven results. Finally, uneven application or coverage, especially in areas with varying textures, can result in inconsistent hardening. Following these best practices helps you achieve a durable and aesthetically pleasing surface.

BANDě Densifier: Features for Polished Concrete

Superior Hardening and Wear Resistance

BANDě’s polished concrete densifier delivers superior hardening for your concrete. You will experience a significant increase in the surface strength. This densifier creates robust, wear-resistant coatings. These coatings dramatically improve abrasion resistance. Your polished floors will withstand heavy foot traffic and daily wear much more effectively. This means your investment in beautiful polished floors lasts considerably longer, maintaining its integrity and appearance.

Effective Pore Blocking and Impermeability

Our advanced densifiers excel at effectively blocking microscopic pores within the concrete. This crucial action makes the surface highly impermeable to liquids. You gain superior protection against a wide range of stains, from oils to chemicals. Spills will simply bead on the surface rather than penetrating, making cleanup effortless. This feature ensures your polished floors maintain their pristine, unblemished look for years.

Eco-Friendly and Safe Formulation

BANDě deeply prioritizes both safety and environmental responsibility. Our densifiers are formulated to be non-toxic and non-flammable. They are entirely water-based, actively contributing to environmental protection and healthier indoor air quality. You can confidently use our polished concrete densifier in various settings, knowing it is safe for both the applicators and the building’s occupants.

Durable and User-Friendly

You will discover BANDě’s densifiers provide an exceptionally durable treatment. This treatment ensures long-lasting performance and protection for your polished concrete floors. The liquid formulation is completely colorless and tasteless, making application straightforward and unobtrusive. Our densifiers are designed to be user-friendly, simplifying your project from start to finish. You achieve professional, high-quality results with remarkable ease.

Future of Concrete Densifiers in 2025

Innovations in Densifier Technology

You will see exciting changes in densifier technology by 2025. Advanced chemical formulations lead to more effective concrete densifiers. These new densifiers cure faster and are environmentally safe. They offer improved penetration and bonding to the concrete surface. Nanotechnology integration uses nanomaterials. This enhances penetration and improves the surface properties of concrete. You will also find more eco-friendly formulations. These low-impact, sustainable densifiers meet strict environmental standards. OEMs focus on deep-penetrating and VOC-free formulations. This ensures enhanced performance and regulatory compliance. They develop one-step and fast-curing densifiers. This supports quicker project turnaround times. You will notice a shift towards lithium silicate and hybrid blends. These strengthen densification and improve aesthetic outcomes. Water-based, spray-on formulations enhance applicator convenience and speed.

Sustainable Solutions and Market Growth

The market for sustainable concrete densifiers is growing. You see a rising demand for eco-friendly materials. Concrete densifiers offer a greener alternative to toxic coatings. Technological advancements create new market opportunities. These improvements offer quicker curing and enhanced durability. The adoption of decorative concrete flooring drives significant growth. Green building practices also increase demand. Stricter environmental regulations push for densifiers that contribute to LEED certification. Modern densifiers often have low VOC formulations. They meet critical indoor air quality standards. Densifiers reduce the need for extra coatings. This aligns with goals for resource efficiency. LEED-friendly concrete densifier floors enable sustainable building. They do not release VOCs. This creates profitable market opportunities for densifiers.

Concrete densifiers are vital for durable, high-quality polished concrete. You must choose the right densifier for your surface. These densifiers offer many benefits, enhancing your surface hardness and impermeability. BANDě provides advanced, environmentally responsible densifiers. Our densifiers ensure your surface remains protected. Select the right densifier for lasting beauty and performance on your concrete surface.

FAQ

What does a concrete densifier do?

You apply a concrete densifier to strengthen your concrete surface. It fills pores and increases hardness. This makes your floor more durable and resistant to wear.

Which densifier type is best for high-traffic areas?

You should choose sodium or potassium silicate densifiers for high-traffic commercial areas. They offer deep penetration and excellent wear resistance. This ensures long-lasting durability.

How often do you need to reapply a densifier?

You typically apply a concrete densifier only once. It creates a permanent chemical reaction within the concrete. This provides lasting protection for your polished floors.