Does your concrete floor suffer from dusting or constant wear? Maintaining concrete can be tough. Chemical floor hardeners offer an excellent solution. A concrete floor hardener transforms concrete from within. This liquid application provides lasting strength and improved performance, giving your concrete floors superior protection.

Key Takeaways

Concrete hardeners make floors stronger. They fill tiny holes in the concrete. This stops dust and wear.

Hardeners protect concrete. They make it resist stains and last longer. This means less cleaning and fewer repairs.

Applying hardeners needs good preparation. Clean the surface well. This helps the hardener work best.

Understanding Concrete Densification: How Hardeners Work

Concrete’s Natural Porosity and Weaknesses

Concrete, despite its reputation for strength, possesses inherent vulnerabilities. Its natural composition includes a network of microscopic pores and capillaries. Untreated concrete surfaces typically have a porosity range where these pores account for 12–18% of the concrete’s total volume. These tiny channels, generally 10–100 nanometers wide, create pathways for moisture, chemicals, and abrasive particles to penetrate the surface. This porosity leads to common issues like dusting, where fine particles break away, and accelerated wear. It also makes the concrete susceptible to micro-pitting, corrosion, freeze-thaw damage, cracking, and chipping. These weaknesses compromise the concrete’s long-term durability and overall performance.

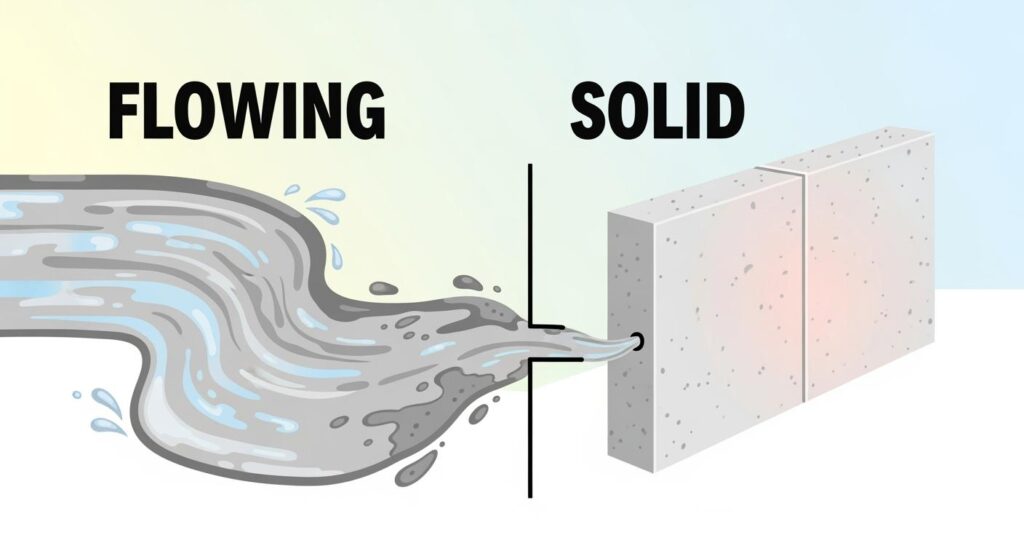

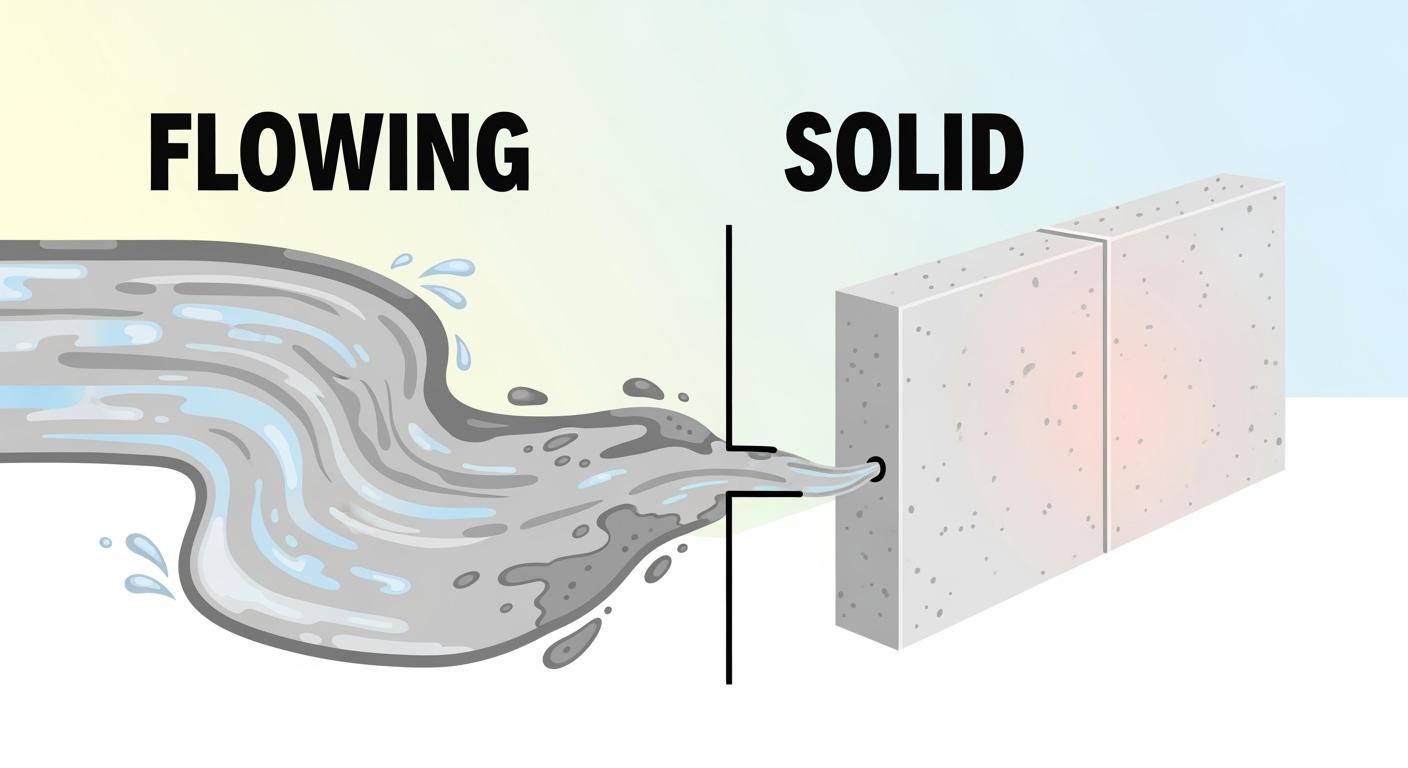

The Chemical Reaction: Liquid to Solid

This is where chemical floor hardeners step in. These liquid solutions penetrate the concrete surface, initiating a remarkable transformation from within. Most chemical hardeners are rich in silica, present as soluble silicates, siliconates, and other proprietary reactive ingredients. Endurable Concrete Hardener, for example, primarily consists of nearly 100% pure silica suspended in a proprietary solution. This silica reacts with unreacted calcium hydroxide, also known as free lime, which is a natural byproduct of cement hydration in the concrete.

Concrete densifiers, which are chemical solutions, react with this free lime and calcium hydroxide in concrete to improve surface hardness and density. First-generation densifiers include magnesium, potassium, and sodium silicates. Second-generation densifiers utilize lithium silicate-based technology and waterborne colloidal silica from nano-sized particles. For instance, Lithi-Tek 4500 reacts with lime to form calcium silicate hydrate (CSH) crystals. This chemical reaction, similar to how pozzolans work, allows the silica in soluble silicate solutions to penetrate the concrete. It remains chemically active as long as moisture is present, eventually hardening into a dense, insoluble mineral. This process effectively converts the liquid application into a solid, integral part of the concrete structure.

Forming CSH Gel for Enhanced Density

The key to this transformation lies in the formation of Calcium Silicate Hydrate (CSH) gel. When the reactive silicates from the concrete floor hardener encounter calcium hydroxide, they chemically combine to produce this incredibly strong, insoluble CSH gel. The chemical formula for Calcium Silicate Hydrate (CSH) gel is given as 3 CaO ⋅ 2 SiO2 ⋅ 4 H2O, or C3S2H4 in cement chemist notation. It is important to note that the stoichiometry of CSH in cement paste is variable, and its exact nanostructure is not yet fully elucidated. This variability is why a hyphen often appears between C, S, and H in its notation.

This newly formed CSH gel fills the microscopic pores and capillaries within the concrete. By filling these voids, the concrete becomes significantly denser and less permeable. This process, known as concrete densification, directly addresses “what is densification.” It means the concrete’s internal structure becomes much tighter and more robust. This enhanced density leads to increased resistance against micro-pitting, corrosion, freeze-thaw damage, cracking, and chipping. The result is a much harder, more durable surface that offers superior protection and improved performance, making a reactive silicate hardener an excellent choice for long-lasting concrete.

Key Benefits of a Hardened Concrete Floor

A concrete floor hardener offers many practical advantages. The increased density and hardness translate into superior wear resistance, reduced dusting, and improved stain resistance. These benefits lead to simplified maintenance, extended floor life, and better resistance to moisture. This blog focuses on liquid chemical hardeners, distinguishing them from dry shake or color hardeners.

Superior Wear and Abrasion Resistance

Hardened concrete floors offer superior wear and abrasion resistance. This is especially critical in high-traffic commercial environments such as warehouses, distribution centers, and industrial facilities. These areas experience significant wear from constant movement, forklifts, and pallet jacks. Using a concrete floor hardener prevents early slab failure in these demanding settings. Research emphasizes the importance of surface treatments like hardeners for enhancing the performance of concrete floors in industrial settings. These hardeners are crucial for improving durability and longevity. They offer cost savings and enhance functionality and safety in industrial concrete floors. These floors must withstand specific requirements like flatness, crack resistance, and load-carrying capacity. They also help prevent dust accumulation from wear and tear. Specifiers should prioritize the abrasion resistance properties of concrete hardeners for industrial applications. Commercial, manufacturing, and warehouse floors specifically require a high-quality work surface with long-term durability, high abrasion resistance, dustproofing, low permeability, and safety.

Dust-Proofing and Stain Protection

The densification process significantly reduces dusting. Untreated concrete often releases fine particles, creating dust that can harm air quality and equipment. A hardened concrete floor locks these particles in, creating a dust-free environment. The densified concrete also becomes highly resistant to many common stains. Think about spills like:

Cola

Grape Juice

Water

BBQ Sauce

Ketchup

Mayonnaise

Salad Dressing

Soy Sauce

Dirty Motor Oil

Diesel Fuel

Brake Fluid

Anti-Freeze

Transmission Fluid

Red Wine

Coffee

Vegetable Oil

Fluoropolymer-based sealers, often used in conjunction with or as part of some chemical floor hardeners, create a long-lasting barrier. This barrier locks out oils, water, and soil from porous materials like concrete. It causes liquids to bead up on the surface for easier cleanup and stain prevention. These sealers also improve chemical and oil resistance, prevent dusting and spalling, and inhibit efflorescence. This provides excellent protection for your concrete.

Reduced Maintenance and Extended Lifespan

Investing in a concrete floor hardener means less work for you in the long run. The increased density and reduced porosity make the floor much easier to clean. Dirt and grime cannot penetrate the surface as easily, so routine cleaning becomes simpler and more effective. This reduction in maintenance needs saves both time and money. Furthermore, the enhanced durability and resistance to wear, abrasion, and chemical attack significantly extend the lifespan of your concrete floor. You get long-lasting protection, delaying the need for costly repairs or replacement. This makes concrete densifiers a smart, cost-effective choice for any facility.

Types of Chemical Floor Hardeners

Many types of chemical floor hardeners exist, primarily falling into the silicate family. These liquid chemical hardeners are different from dry shake or color hardeners, which are typically broadcast onto fresh concrete. Common silicate-based hardeners include lithium, sodium, and potassium silicates. For example, products like TK-LS Hard and TK-LS Hard N Guard use premium lithium silicate technology. PS103 is another premium lithium silicate solution. SureHard and SureHard LS are water-based, liquid-chemical, silicate hardening and dustproofing solutions, with SureHard LS specifically using lithium silicate. SureHard PSR is a hybrid penetrating and surface sealer composed of potassium silicates for hardening and dustproofing, and acrylic resins for sealing and protection.

Each type offers distinct characteristics. Here is a comparison of lithium silicate and sodium silicate hardeners:

Feature | Lithium Silicate | Sodium Silicate |

|---|---|---|

Composition | Smaller molecular structure, allowing for deeper penetration. | Larger molecular structure, resulting in less penetration. |

Reactivity | Highly reactive, forming a denser, harder surface. | Less reactive, leading to a less dense and less hard surface. |

Application | Easier to apply, dries quickly, and leaves no residue. | Can be more difficult to apply, may leave a white residue if not properly rinsed. |

Durability | Superior abrasion resistance and longer-lasting. | Good abrasion resistance, but generally less durable than lithium silicate. |

Cost | Generally more expensive. | Generally less expensive. |

Efflorescence | Helps to reduce efflorescence. | Less effective at reducing efflorescence. |

Environmental Impact | More environmentally friendly due to lower VOCs and easier cleanup. | Can be less environmentally friendly due to higher alkalinity and potential for residue. |

Uses | Ideal for high-traffic areas, industrial floors, and polished concrete. | Suitable for general concrete hardening and dust-proofing in less demanding environments. |

Maintenance | Low maintenance, easy to clean. | Requires more attention during application to avoid residue, and may need more frequent reapplication. |

Curing Time | Faster curing time. | Slower curing time. |

Water Resistance | Provides better water resistance. | Provides good water resistance, but not as effective as lithium silicate. |

Stain Resistance | Offers better stain resistance. | Offers good stain resistance, but not as effective as lithium silicate. |

Breathability | Maintains concrete’s breathability. | Maintains concrete’s breathability. |

Chemical Resistance | Superior chemical resistance. | Good chemical resistance. |

Substrate Compatibility | Compatible with a wider range of concrete types. | May have limitations with certain concrete types. |

Surface Preparation | Requires less rigorous surface preparation. | May require more thorough surface preparation to prevent residue. |

Odor | Low odor. | Can have a stronger odor. |

UV Stability | Excellent UV stability, will not yellow. | Good UV stability, but some formulations may yellow over time. |

Slip Resistance | Does not affect slip resistance. | Does not affect slip resistance. |

Penetration Depth | Deeper penetration. | Shallower penetration. |

Reaction Byproducts | Forms a permanent bond with the concrete. | Forms a permanent bond with the concrete. |

Alkali-Silica Reaction (ASR) | Helps to mitigate ASR. | Less effective at mitigating ASR. |

Dust-Proofing | Excellent dust-proofing. | Good dust-proofing. |

Hardness Improvement | Significantly improves surface hardness. | Improves surface hardness to a good extent. |

Gloss Enhancement | Can enhance gloss on polished concrete. | Less effective at enhancing gloss. |

Chloride Resistance | Better chloride resistance. | Good chloride resistance. |

Freeze-Thaw Resistance | Improves freeze-thaw resistance. | Improves freeze-thaw resistance. |

Abrasion Resistance | Higher abrasion resistance. | Good abrasion resistance. |

Scratch Resistance | Higher scratch resistance. | Good scratch resistance. |

Blushing | Less prone to blushing. | More prone to blushing if not applied correctly. |

Shelf Life | Longer shelf life. | Shorter shelf life. |

Storage | Less sensitive to storage conditions. | More sensitive to storage conditions. |

Mixing | Typically ready-to-use, no mixing required. | Some formulations may require mixing. |

Coverage Rate | Higher coverage rate due to deeper penetration. | Lower coverage rate. |

Residue | No residue. | Can leave a white residue if not rinsed properly. |

Crystallization | Forms smaller, more stable crystals within the concrete. | Forms larger, less stable crystals within the concrete. |

Hydrophobic Properties | Can contribute to hydrophobic properties. | Less contribution to hydrophobic properties. |

Repairability | Easier to repair and reapply without issues. | May require more effort to repair or reapply due to potential residue. |

Compatibility with Coatings | Excellent compatibility with subsequent coatings. | Good compatibility with subsequent coatings, but residue must be removed. |

Odor during Application | Very low to no odor. | Can have a noticeable odor. |

Flash Point | Non-flammable. | Non-flammable. |

VOC Content | Very low VOC content. | Low to moderate VOC content. |

pH Level | Neutral to slightly alkaline. | Highly alkaline. |

Safety | Safer to handle due to lower alkalinity. | Requires more caution due to higher alkalinity. |

Availability | Widely available. | Widely available. |

Brand Variety | Many brands offer lithium silicate. | Many brands offer sodium silicate. |

Market Trend | Growing in popularity due to superior performance. | Established product, still widely used for cost-effectiveness. |

Customer Satisfaction | Generally higher customer satisfaction due to ease of use and performance. | Good customer satisfaction, especially for budget-conscious projects. |

Technical Support | Good technical support available. | Good technical support available. |

Warranty | Often comes with longer warranties. | Standard warranties. |

Regulatory Compliance | Meets most environmental regulations. | Meets most environmental regulations. |

Application Temperature | Wider range of application temperatures. | More sensitive to application temperatures. |

Freeze Protection | Provides better freeze protection for concrete. | Provides good freeze protection for concrete. |

Heat Resistance | Improves heat resistance of concrete. | Improves heat resistance of concrete. |

Chemical Reaction | Reacts with calcium hydroxide to form calcium silicate hydrate (CSH). | Reacts with calcium hydroxide to form calcium silicate hydrate (CSH). |

Ionic Size | Lithium ions are smaller. | Sodium ions are larger. |

Migration | Lithium ions migrate deeper into the concrete. | Sodium ions migrate less deeply into the concrete. |

Water Spotting | Less prone to water spotting. | More prone to water spotting if not properly applied. |

Chalking | Reduces chalking. | Reduces chalking. |

Crazing | Helps prevent crazing. | Helps prevent crazing. |

Shrinkage | Does not contribute to shrinkage. | Does not contribute to shrinkage. |

Expansion | Does not contribute to expansion. | Does not contribute to expansion. |

Bonding Strength | Improves bonding strength of concrete. | Improves bonding strength of concrete. |

Compressive Strength | Increases compressive strength. | Increases compressive strength. |

Flexural Strength | Increases flexural strength. | Increases flexural strength. |

Impact Resistance | Improves impact resistance. | Improves impact resistance. |

Permeability Reduction | Significantly reduces permeability. | Reduces permeability. |

Vapor Transmission | Reduces vapor transmission. | Reduces vapor transmission. |

Alkalinity | Lower alkalinity. | Higher alkalinity. |

Neutralization | Neutralizes free lime more effectively. | Neutralizes free lime. |

Crystalline Structure | Forms a more refined crystalline structure. | Forms a less refined crystalline structure. |

Surface Density | Creates a denser surface. | Creates a good surface density. |

Pore Filling | More effectively fills pores. | Fills pores to a good extent. |

Micro-Cracking | Helps to reduce micro-cracking. | Helps to reduce micro-cracking. |

Curing Compound Compatibility | Compatible with most curing compounds. | Compatible with most curing compounds. |

Adhesion | Improves adhesion of subsequent coatings. | Improves adhesion of subsequent coatings. |

Cost-Effectiveness (Long-term) | More cost-effective in the long run due to durability. | Less cost-effective in the long run due to potential for reapplication. |

Ease of Cleanup | Easy cleanup with water. | Requires thorough rinsing to avoid residue. |

Residue Removal | No residue to remove. | Residue must be removed to avoid white marks. |

Health Hazards | Lower health hazards. | Higher health hazards due to alkalinity. |

Safety Equipment | Less extensive safety equipment required. | More extensive safety equipment required. |

Disposal | Easier disposal. | Requires more careful disposal due to higher alkalinity. |

Applying Concrete Hardeners: A Step-by-Step Guide

Applying concrete hardeners correctly ensures the best results. This process involves careful preparation, precise application, and proper post-treatment.

Essential Surface Preparation

Proper surface preparation is crucial for effective hardener application. First, inspect the existing concrete substrate thoroughly. Look for cracks, uneven areas, stains, and any old coatings or adhesives. These all require removal. Use industrial grinders with metal-bonded diamond abrasives to remove surface contaminants and old sealers. This process also opens up the concrete pores. Begin grinding with coarse grits to level the floor and remove blemishes. Then, use progressively finer grits of diamond abrasives. Repair minor cracks or holes using patching materials that blend with the finished look. Finally, clean the concrete surface and vacuum it thoroughly to remove all dust and debris.

Application Techniques for Optimal Results

Once the surface is ready, you can apply the hardener. Optimal environmental conditions are important. The temperature for applying and curing hardeners should be between 60°F (15°C) and 90°F (32°C). This range helps the chemicals react properly. Humidity also matters. High humidity requires a higher substrate temperature to prevent condensation. Low humidity reduces these concerns. Coverage rates for concrete hardeners are approximate. For example, Watco Floors’ Concrete Binder & Hardener covers about 325 sq. ft. per 1.3 gallons. This rate can vary based on the concrete’s porosity. Always perform test applications on actual surfaces to find the precise coverage. Typically, one coat is enough for most surfaces.

Curing and Post-Application Care

After applying the hardener, proper curing and care extend the floor’s life. Use pH-neutral cleaning solutions to avoid damaging the concrete’s surface and gloss. Clean spills immediately with a microfiber or dry dust mop to prevent stains. Schedule regular cleaning and maintenance to keep floors free from dust, dirt, and scuffs. Avoid using wax, as it can build up and remove shine. Clean floors section by section for thorough results. For newly hardened concrete floors, professional polishing is recommended every two to three years. This frequency may increase in high-traffic areas. Do not attempt this as a DIY project to avoid uneven results.

Concrete floor hardeners truly transform vulnerable concrete into a high-performance, durable surface. These chemical floor hardeners offer enhanced durability, dust-proofing, stain resistance, and reduced maintenance. Investing in concrete densification provides long-term value and cost-effectiveness for any concrete. They offer superior protection for your concrete floors.

FAQ

What is the main purpose of a concrete hardener?

Concrete hardeners strengthen floors. They densify the surface, preventing dusting and wear. This creates a more durable, long-lasting concrete.

Can you apply a hardener to old concrete?

Yes, you can apply hardeners to old concrete. Proper surface preparation is key. This ensures the hardener penetrates and reacts effectively.

How long does a hardened concrete floor last?

A properly hardened concrete floor can last for many years. Its lifespan depends on traffic and maintenance. Regular care extends its durability.

See Also

Unveiling the Science Behind Concrete Surface Hardener Functionality

Understanding Liquid Concrete Floor Hardeners, Sealers, and Densifiers

Distinguishing Concrete Densifiers from Hardeners: A Clear Explanation

Exploring Concrete Floor Hardeners: Their Purpose and Operational Mechanics

The Essential 2025 Guide for Choosing Your Ideal Concrete Hardener