Selecting the right floor hardener is crucial for ensuring durability and performance. A suitable hardener enhances the concrete’s strength and resistance to wear. Consider factors such as the type of concrete and the conditions of use. For instance, the environment and expected traffic levels play significant roles in this decision. For those in Jakarta, exploring options like jual floor hardener Jakarta can provide valuable insights.

Key Takeaways

Choosing the right floor hardener boosts concrete strength and durability. Consider factors like traffic load and surface type for optimal performance.

Dry shake hardeners offer superior abrasion resistance and aesthetic appeal. They are ideal for high-traffic areas like warehouses and factories.

Liquid densifiers are easier to apply on cured concrete. They enhance surface density and reduce dust, making maintenance simpler.

Floor Hardener Types

Dry Shake Hardeners

Dry shake hardeners are a popular choice for enhancing the durability of concrete surfaces. These hardeners consist of a blend of natural quartz aggregates and other materials. They are applied to freshly poured concrete before it sets. The application process requires skilled labor and precise timing to ensure optimal bonding.

The benefits of dry shake hardeners include:

Superior Abrasion Resistance: They create a tough surface that withstands heavy foot and vehicle traffic.

Enhanced Aesthetic Appeal: Available in various colors, they can improve the visual appeal of industrial and commercial spaces.

Long-Term Durability: Once cured, these hardeners significantly reduce maintenance needs.

In Jakarta, dry shake hardeners are commonly used in flooring applications, particularly in warehouses and manufacturing facilities. They improve wear resistance and reduce dusting, which is essential for maintaining a clean workspace.

Application Type | Benefits |

|---|---|

Flooring | Improves wear resistance, reduces dusting, enhances surface permeability |

Liquid Densifiers

Liquid densifiers are another effective type of floor hardener. They are typically applied to cured concrete surfaces, making them easier to use than dry shake hardeners. The application involves spraying or rolling the liquid onto the surface, allowing it to penetrate and react with the concrete.

The key advantages of liquid densifiers include:

Enhanced Strength: They chemically react with free lime in the concrete, filling pores and increasing density.

Dustproofing: The densification process tightens the surface, reducing dust and improving air quality.

Cost-Effectiveness: Liquid densifiers often have lower material costs and require less labor-intensive application compared to dry shake hardeners.

However, liquid densifiers have limitations. They primarily strengthen the surface rather than the entire slab, resulting in limited impact resistance. This makes them suitable for environments with moderate traffic but less ideal for heavy-duty applications.

Feature | Dry Shake Hardeners | Liquid Densifiers |

|---|---|---|

Application Method | Applied to fresh, wet concrete; requires skilled labor and precise timing. | Applied to cured concrete; simpler application process. |

Performance | Creates a tough, durable surface; superior abrasion and impact resistance. | Primarily densifies the surface; limited impact resistance. |

Cost | Higher material and labor costs; lower long-term maintenance. | Lower material costs; less labor-intensive application. |

Choosing the Right Concrete Hardener

Traffic Load

When selecting a concrete hardener, assessing the traffic load is essential. Different environments impose varying demands on flooring. For high-traffic industrial areas, the choice of hardener can significantly impact performance and longevity.

Epoxy coatings are highly recommended for these settings. They offer exceptional resistance to heavy loads, making them ideal for warehouses and manufacturing facilities.

Additionally, epoxy coatings resist scratches and chemicals, which is crucial for maintaining flooring in high-traffic environments.

In Jakarta, where industrial activities are prevalent, choosing the right concrete hardener can enhance safety and reduce maintenance costs. For instance, Sikafloor® CureHard-24, a sodium silicate-based liquid, is suitable for both fresh and hardened concrete. This versatility allows for various application conditions, ensuring that the flooring remains durable under demanding circumstances.

Surface Type

Understanding the surface type is equally important when choosing the right concrete hardener. Different surfaces, such as new slabs, old floors, pavers, or bricks, require specific considerations.

New Concrete Slabs: For freshly poured concrete, a step-by-step guide is crucial for optimal results.

Prepare the concrete surface by ensuring it is leveled and at the ‘plastic’ stage.

Distribute approximately two-thirds of the recommended amount of dry-shake hardener evenly over the surface.

Use a bull float or power trowel to work the hardener into the concrete.

Apply the remaining one-third of the hardener and repeat the floating process.

Finally, use a power trowel to smooth the surface and keep it moist for the recommended curing period.

Existing Concrete Floors: For older surfaces, liquid densifiers may be more appropriate. They penetrate the concrete and react chemically to create a denser, harder layer. This choice improves the floor’s resistance to chemicals and abrasion, making it less porous and easier to maintain.

Details | |

|---|---|

Abrasion Resistance | Essential for surfaces to withstand wear from vehicular traffic and other forces. |

Recommended Hardener | SCG 500, applied via dry shake method for a durable surface. |

Average Consumption | 3 to 7 kg of SCG 500 powder per m², with a thickness of 2 – 3 mm for optimal performance. |

By carefully considering both traffic load and surface type, you can make an informed decision when choosing the right concrete hardener. This approach ensures that the flooring meets the demands of its environment while maintaining durability and safety.

Where to Buy Floor Hardener in Jakarta

Reputable Distributors

Finding a reliable distributor for floor hardeners in Jakarta is essential for ensuring quality and performance. Here are some criteria to evaluate potential distributors:

Assessment Description | High-Quality Indicators | |

|---|---|---|

Industry Experience | Track record of similar warehouse/factory projects. | Relevant portfolio and active references. |

Operator Expertise | Ability to operate precision trowel machines. | Certification or field skill demonstration. |

Time Management | Understanding of concrete setting time. | Documented QC procedures for application timing. |

Material Quality | Technical specifications of the floor hardener used. | Use of reputable brands & data transparency. |

When searching for distributors, consider conducting thorough research on those with a strong digital presence. Evaluate their product portfolio for a variety of brands and types. Additional services like technical support and site visits can also be beneficial.

Professional Applicators

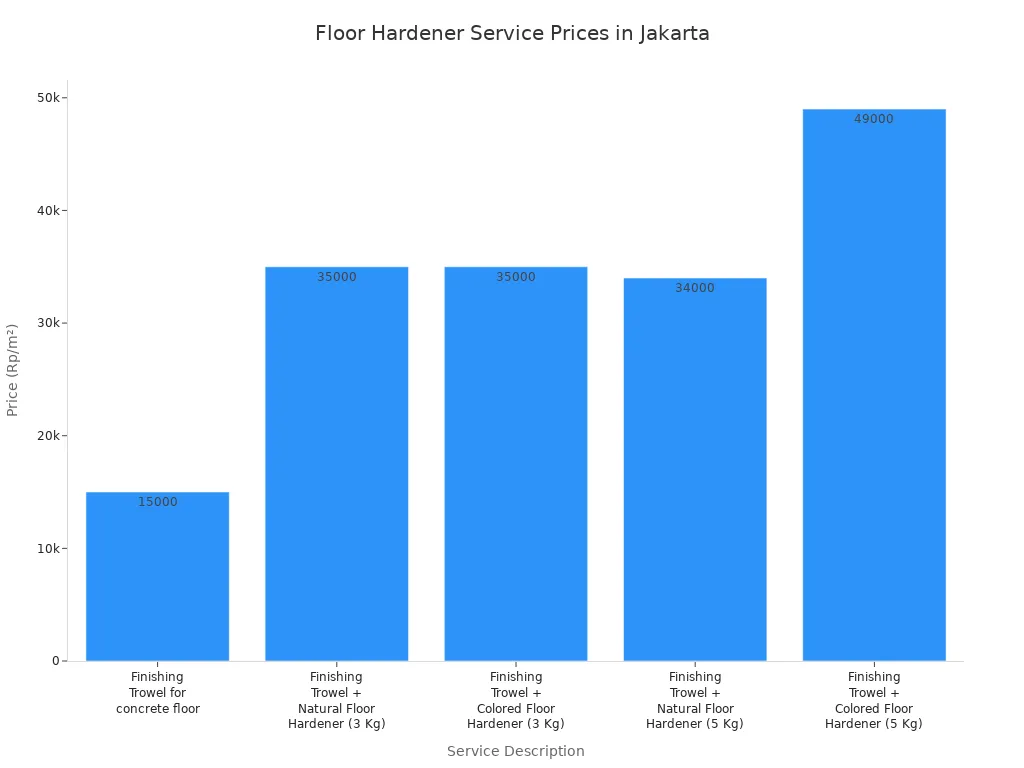

Hiring professional applicators ensures that the floor hardener application is executed correctly. The costs associated with these services can vary. Below is a table outlining typical prices for various services in Jakarta:

Service Description | Price (Rp/m²) |

|---|---|

Finishing Trowel for concrete floor | 15,000 |

Finishing Trowel + Natural Floor Hardener (3 Kg) | 35,000 |

Finishing Trowel + Colored Floor Hardener (3 Kg) | 35,000 |

Finishing Trowel + Natural Floor Hardener (5 Kg) | 34,000 |

Finishing Trowel + Colored Floor Hardener (5 Kg) | 49,000 |

The general price range for floor hardener services typically falls between Rp 30,000 and Rp 90,000 per square meter. Engaging skilled applicators can significantly enhance the durability and appearance of your flooring.

Choosing the right distributor and professional applicator is vital for achieving optimal results in your floor hardener application.

Selecting the right floor hardener is vital for ensuring durability and performance in commercial buildings. Consider the following long-term benefits:

Excellent wear resistance

Chemical and stain resistance

Ease of maintenance

Versatility across environments

Cost-effective investment

Consulting with professionals can provide tailored advice for your specific needs.

FAQ

What is the purpose of using floor hardeners?

Floor hardeners enhance concrete strength, improve abrasion resistance, and reduce dusting, making surfaces more durable and easier to maintain.

How do I apply a dry shake hardener?

Apply dry shake hardener to freshly poured concrete before it sets. Use a bull float to work it into the surface for optimal bonding.

Can I use liquid densifiers on old concrete?

Yes, liquid densifiers are suitable for old concrete. They penetrate and react chemically, increasing surface density and durability.

See Also

Top Floor Hardening Options for Philippine Warehouses

Premier Floor Hardening Solutions for UK Industrial Spaces

Understanding BANDě Concrete Floor Hardener: Key Insights

Understanding Floor Hardeners: Functionality and Benefits Explained

Comprehensive Guide to Choosing BANDě Floor Hardener for 2025