Frustrated with peeling, chipping epoxy garage floors? You need a lasting concrete solution. A concrete densifier offers a superior, low-maintenance alternative for your garage surface. For Sydney, Melbourne, and Brisbane homeowners, a one-step concrete densifier sydney like BANDě Crystal Floor Hardener is your ultimate upgrade. Its easy application transforms your concrete flooring. This densifier strengthens the concrete surface.

Key Takeaways

Concrete densifiers make your garage floor much stronger. They go deep into the concrete. This stops peeling and chipping, unlike epoxy.

Densified floors are easy to clean. They do not trap dirt. You can use simple soap and water. This saves you time and effort.

Densifiers let your concrete breathe. This stops moisture problems. Epoxy can trap moisture. This causes bubbles and damage.

Densifiers vs. Epoxy: Garage Floor Superiority

Are you tired of your garage floor letting you down? Many homeowners in Sydney, Melbourne, and Brisbane choose epoxy, but often find themselves facing frustrating issues. Let’s explore why a concrete densifier offers a far superior solution for your garage.

Durability and Longevity

Epoxy coatings might look great initially, but they often struggle with the harsh realities of a garage environment. You see them peel, chip, and scratch under the weight of vehicles, tools, and everyday wear. This happens because epoxy is a surface coating; it sits on your concrete. When that bond breaks, you get those unsightly flakes and bare patches.

A densifier works differently. It penetrates deep into your existing concrete, reacting chemically to create a much harder, denser surface. This isn’t a coating that can peel off; it becomes an integral part of the concrete itself. Think of it as strengthening the very structure of your floor. This means your garage floor can withstand heavy traffic, impacts, and abrasions for many years, offering incredible longevity you simply won’t get from epoxy.

Easy Maintenance and Cleaning

Maintaining an epoxy floor can be a chore. You often need specific cleaners, and spills can sometimes stain the surface if not cleaned quickly. Plus, those chips and peels? They trap dirt and make cleaning even harder.

With a densified concrete floor, maintenance becomes incredibly simple. The process makes your concrete less porous and much smoother. This means dirt, oil, and other spills sit on the surface, making them easy to wipe away. You won’t need special chemicals; a simple mop and water usually do the trick. Imagine a garage floor that stays cleaner with less effort – that’s what a densifier gives you.

Breathability and Moisture Control

One major drawback of epoxy is its inability to breathe. Your concrete slab naturally releases moisture vapour from the ground beneath. When you seal it with an impermeable epoxy coating, that moisture gets trapped. This can lead to bubbling, delamination, and an overall failure of the epoxy system. It’s a common problem, especially in humid climates like those found in parts of Sydney, Melbourne, and Brisbane.

A concrete densifier, however, allows your concrete to breathe. It hardens and densifies the surface without creating an impenetrable barrier. This means moisture can still escape, preventing those moisture-related issues that plague epoxy floors. Your garage floor remains stable and healthy, free from the problems caused by trapped moisture.

Cost-Effective, Simple Application

When you consider the total cost, a densifier often proves to be a more economical choice in the long run. Let’s look at epoxy first. For materials alone, water-based epoxy can cost you around $15-$20 per square metre, while solvent-based or solid epoxy might be $30-$40 per square metre. If you include labour and materials for a standard epoxy finish, you’re looking at $30-$35 per square metre. For decorative finishes, like flakes or metallics, the price jumps significantly to $80-$100 per square metre, and epoxy flake flooring can even reach $100 to $130 per square metre.

Now, compare that to a one-step concrete densifier. The material cost is typically much lower, and the application process is far simpler. You don’t need multiple coats, extensive drying times between layers, or specialised equipment. This straightforward application saves you both time and money, whether you’re doing it yourself or hiring a professional. You get a durable, long-lasting concrete floor without the hefty price tag and complex installation of epoxy.

Understanding Concrete Densifiers

How Densifiers Strengthen Concrete

You might wonder how a liquid can make your concrete floor so much stronger. It’s all about chemistry! A concrete densifier works by reacting with your existing concrete. Silicate densifiers, like the ones we discuss, find calcium hydroxide within the concrete. This calcium hydroxide is a soft byproduct from the concrete’s original hydration process. It doesn’t really add much strength. The densifier chemically reacts with this calcium hydroxide, causing it to harden. This process creates calcium silicate hydrate (CSH), the main component giving concrete its strength. This chemical hardening and densifying of the concrete surface usually takes a week or two to fully develop.

Types of Concrete Densifiers

Different types of densifiers exist, mainly categorised by their silicate base: Sodium, Potassium, and Lithium. Each offers unique characteristics. Sodium and Potassium silicates have been around for a while. However, lithium-based densifiers provide some distinct advantages.

Lithium Densifiers for Garages

For your garage floor, lithium densifiers are often the top choice. They react faster and penetrate deeper into the concrete compared to sodium and potassium silicates. This means you get a stronger, denser concrete surface more quickly. Lithium densifiers are also widely preferred for polished concrete application because they help achieve a glossy, shiny finish. They work better for dense concrete and leave less residue after application, making cleanup easier. Plus, they have a lower pH, which reduces the chance of “bloom” – those white, powdery deposits you sometimes see. This faster, deeper reaction improves strength and reduces porosity, making them ideal for high-performance concrete floors.

Dust-Proofing and Abrasion Resistance

One fantastic benefit of using a densifier is its ability to dust-proof your concrete. By hardening the concrete surface, you significantly reduce the amount of dust released. This makes your garage much cleaner. The increased density also means your concrete surface becomes far more resistant to abrasion, standing up better to daily wear and tear from vehicles and tools.

Choosing Your Concrete Densifier

Choosing the right concrete densifier for your garage floor project is a crucial step. You want to make sure you pick the best product for your specific needs. This section will help you understand what to look for.

Assessing Your Concrete Floor

Before you choose a concrete densifier, you should take a good look at your existing concrete floor. Is it old or new? Does it have any existing coatings or sealers? These factors can affect how the densifier works. You might want to consult with a concrete professional. They can help you understand the unique characteristics of your floor. You can also speak directly with the product manufacturer, for example, about BANDě Crystal Floor Hardener. This ensures you pick the most suitable densifier for your specific concrete.

Key Selection Factors

When you select a densifier, think about what you want your concrete floor to look like and how you will use it. Do you want a high sheen, or is deep penetration more important to you? Some densifiers are better for achieving a glossy finish, while others focus more on hardening the concrete deep down. Remember, coatings are often used for concrete surfaces that will experience high traffic, whether from foot or vehicles. Your garage floor definitely fits this description. Also, consider if you need petrol resistance, which is important for garage floors.

Recommended Densifiers

For garage floors, you need a product that offers excellent durability and performance. BANDě Crystal Floor Hardener is a prime example of a high-quality, one-step lithium concrete densifier. It is perfect for garage floors. Other excellent options are available too. For instance, Concrete Shield™ Premium Lithium Densifier is a high-performance Nano Lithium Silicate solution. It includes penetration additives for premium polished concrete floors. Another great choice is Concrete Shield™ Potassium Lithium Silicate. This is a ready-to-use blend that you can use to polish, harden, and seal green or aged concrete. These types of densifiers and hardeners work by infusing the concrete’s pores. This creates a compact and very strong surface.

Local Conditions: Sydney, Melbourne, Brisbane

The local conditions in Sydney, Melbourne, or Brisbane can also influence your choice. For example, areas with higher humidity might benefit even more from a densifier’s breathability. This helps prevent moisture issues in your concrete. A good concrete densifier sydney will perform well in these varied Australian climates. No matter where you are, selecting a quality densifier for your concrete projects ensures a long-lasting and robust garage floor.

Applying Your One-Step Densifier

Surface Preparation

Before you apply your one-step densifier, proper preparation of your concrete floor is absolutely vital. This ensures the best results for your project. You need to get the existing concrete ready. This step is crucial for the densifier to penetrate and react effectively with the concrete surface.

You must clean the concrete subfloor thoroughly.

Grind down any high spots or imperfections on the concrete surface.

Remove any existing coating, adhesive, or membrane from the concrete.

Repair any cracks and joins in the concrete surface.

Patch and repair any other surface imperfections.

Application Steps

Once your concrete surface is clean and ready, applying the concrete densifier is straightforward. You will need a few simple tools for this application. These include a hand sprayer or a low-pressure sprayer, and a clean broom or microfibre mop.

Use your sprayer to apply the densifier evenly across the concrete surface.

Work the densifier into the concrete surface with your broom or mop.

Ensure the entire surface remains wet for the recommended time, usually 15-20 minutes. Do not let it dry out.

Remove any excess densifier from the surface after the dwell time.

Allow the concrete to cure. The full hardening process for the concrete surface takes about a week or two.

Troubleshooting Common Issues

Even with careful application, you might encounter some issues. Here are common problems and their solutions for your concrete surface:

Issue | Cause | Troubleshooting Solution |

|---|---|---|

Bubbling | Over-application; Application in hot weather or direct sun (sealer ‘skins over’) | Apply thinly (e.g., 5 mils wet, 2 mils dry for acrylic sealer); Apply during coolest part of the day, avoiding direct sun. |

Blushing (turns white, peels, or flakes) | Application to wet concrete or fresh concrete with bleed water; Applying too thick | Ensure concrete surface is dry; Apply thinly. |

White or powdery | Low temperature (below 10°C) or high humidity (above 32°C) during application | Check temperature and humidity guidelines; Apply early in the day in colder climates. |

Safety First

Always prioritise safety during your application. Wear appropriate personal protective equipment. This includes gloves and eye protection. Ensure good ventilation in your garage. This protects you while working on your concrete surface.

Maximising Your Densified Floor

Optional Sealing

You have transformed your garage floor with a densifier, but you can add more protection. Consider an optional sealer for your concrete. This extra layer offers significant benefits. Penetrating sealers enter the concrete pores, making the concrete surface water-repellent. Topical sealers create a hard, durable coating on the concrete surface. They offer high protection against stains and abrasions, making the surface waterproof and easy to clean. Your choice depends on your project’s desired outcome. Sealants shield your concrete from oil, UV rays, and weather. They extend its lifespan and help preserve its colour.

Ongoing Maintenance

Keeping your densified floor in top condition is simple. Use microfibre mops and pH-neutral cleaners. These clean without damaging the concrete or any protective sealants. Avoid harsh chemicals. For daily care, sweep thoroughly with a microfibre dust mop. Spot clean spills immediately. Weekly, use a flat mop with a diluted pH-neutral cleaner. Apply a penetrating sealer annually. For high-traffic areas, consider a sacrificial wax every three to six months.

Long-Term Benefits

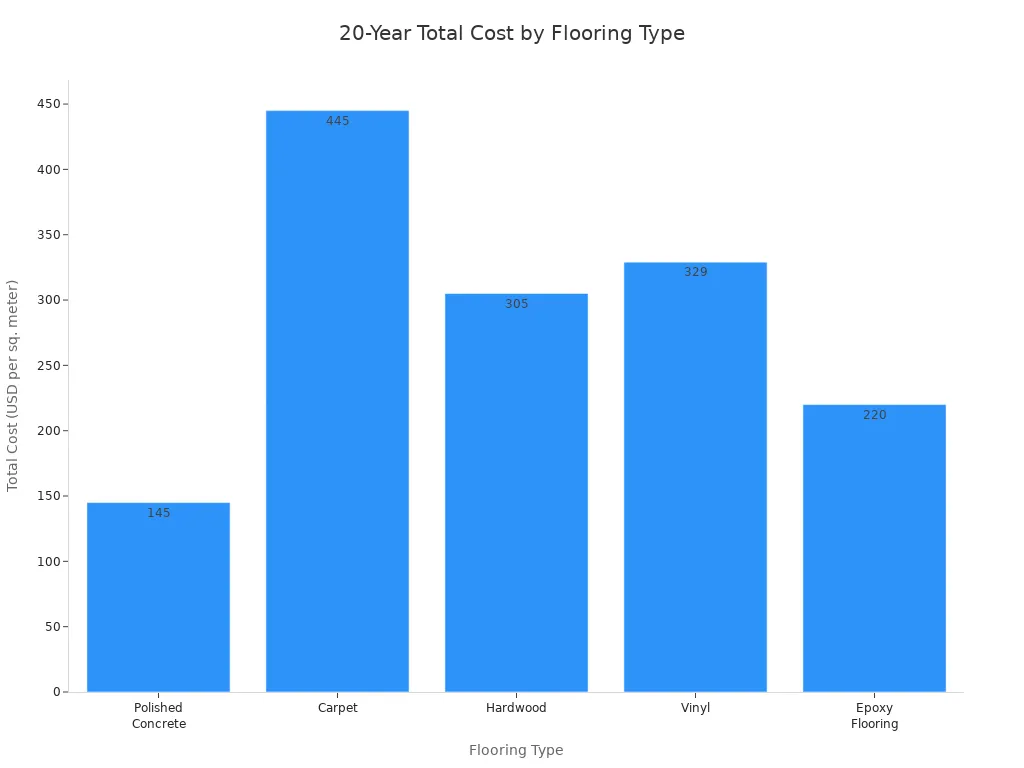

You will see significant long-term cost savings with a densified concrete floor. It outperforms other flooring options over 10-15 years. Polished concrete offers superior durability. It lasts 20+ years, often indefinitely with proper maintenance. It only needs occasional re-polishing. Most other flooring materials, like carpet or hardwood, need replacement every 5-15 years. Epoxy flooring requires complete recoating every 5-10 years. Polished concrete has minimal maintenance. It eliminates the need for regular refinishing or replacement cycles. This saves you money over time. Look at this comparison:

Flooring Type | Initial Cost (per sq. metre) | Annual Maintenance (per sq. metre) | Replacement/Refinishing Cycle | Total Cost (20 years, per sq. metre) |

|---|---|---|---|---|

Polished Concrete | $30-120 | $2-5 | None (lasts 20+ years) | $70-220 |

Carpet | $50-110 | $10-20 | Every 7-14 years | $320-570 |

Hardwood | $80-150 | $5-10 | Refinishing every 8-16 years | $240-370 |

Vinyl | $50-110 | $3-8 | Every 12 years | $210-448 |

Epoxy Flooring | $30-120 | More frequent than polished concrete | Recoating every 5-10 years | Higher than polished concrete due to recoating |

This table clearly shows the value. You make a smart investment for all your concrete projects.

You should choose a concrete densifier, like BANDě Crystal Floor Hardener. It offers a superior, durable, and easy-to-maintain alternative to epoxy for your garage flooring in Sydney, Melbourne, and Brisbane. This one-step concrete densifier sydney provides durability, low maintenance, breathability, and easy application. Make the smart switch for a long-lasting, high-performance concrete densifier sydney garage floor.

FAQ

Can you apply a densifier over an existing epoxy floor?

No, you cannot. You must remove all existing coatings first. The densifier needs direct contact with the bare concrete to react properly and strengthen your floor.

How long will my densified garage floor last?

A densified floor lasts for decades, often the lifetime of the concrete itself. It becomes part of the concrete, not a coating that wears away. You get lasting durability.

Will a concrete densifier change the colour of my garage floor?

Generally, no. A densifier enhances the natural look of your concrete. It might slightly deepen the colour, giving it a richer appearance. You will love the subtle change.

See Also

Effortless Garage Floor Upgrade: Discover This One-Step Densifier Solution

Selecting the Ideal Concrete Densifier for Your Warehouse Flooring Needs

Top Floor Hardener Solutions for Philippine Warehouses Revealed

Discovering the Perfect Epoxy Concrete Patch for Your Construction Project

2025 Guide: Choosing the Ultimate Concrete Floor Hardener for You