Your floors are a big investment. Their durability is crucial for both homes and businesses. Protecting them with floor hardening extends their lifespan, cuts maintenance costs, and looks great. How do you pick the right hardening method for your specific floor? This process protects against wear, abrasion, and chemical damage, boosting strength and durability.

Key Takeaways

Floor hardening makes floors stronger and last longer. It protects them from daily wear and tear.

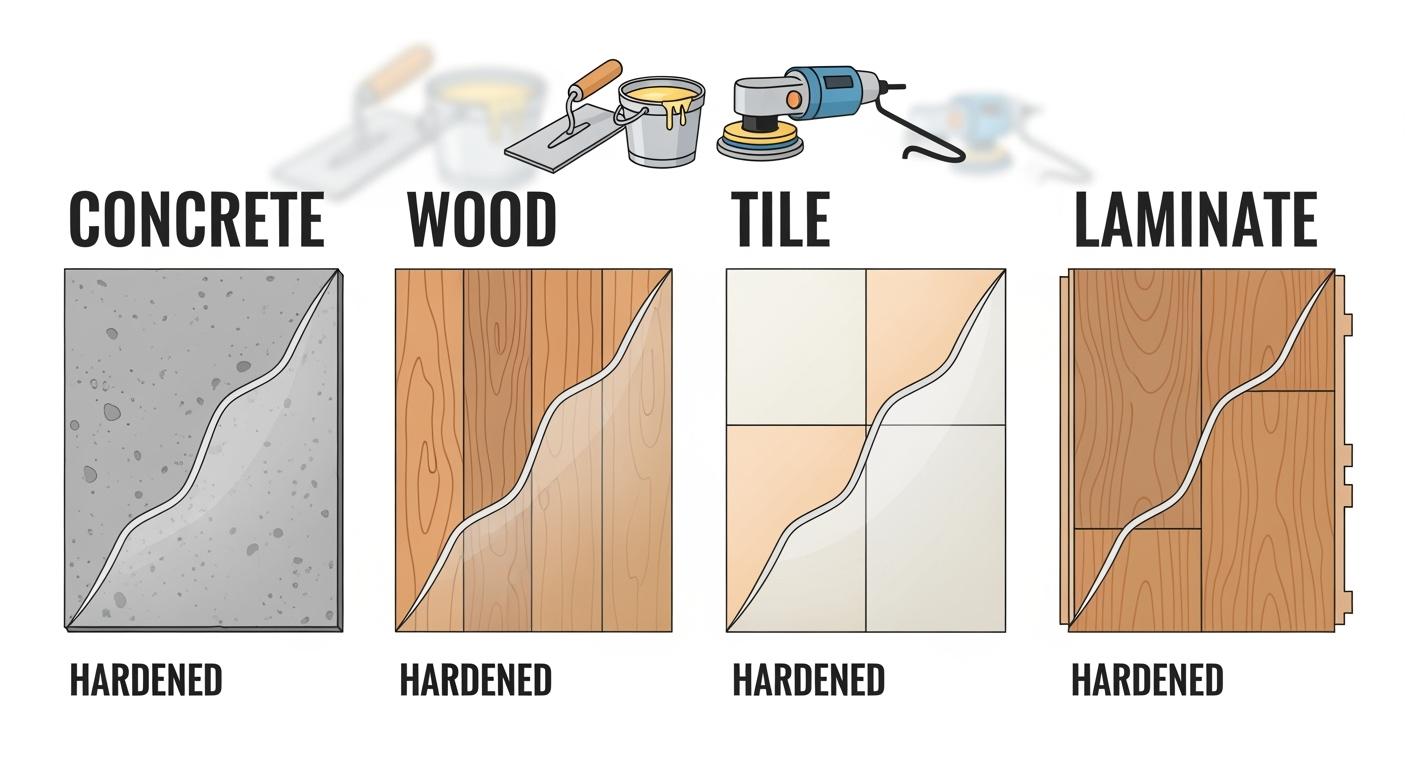

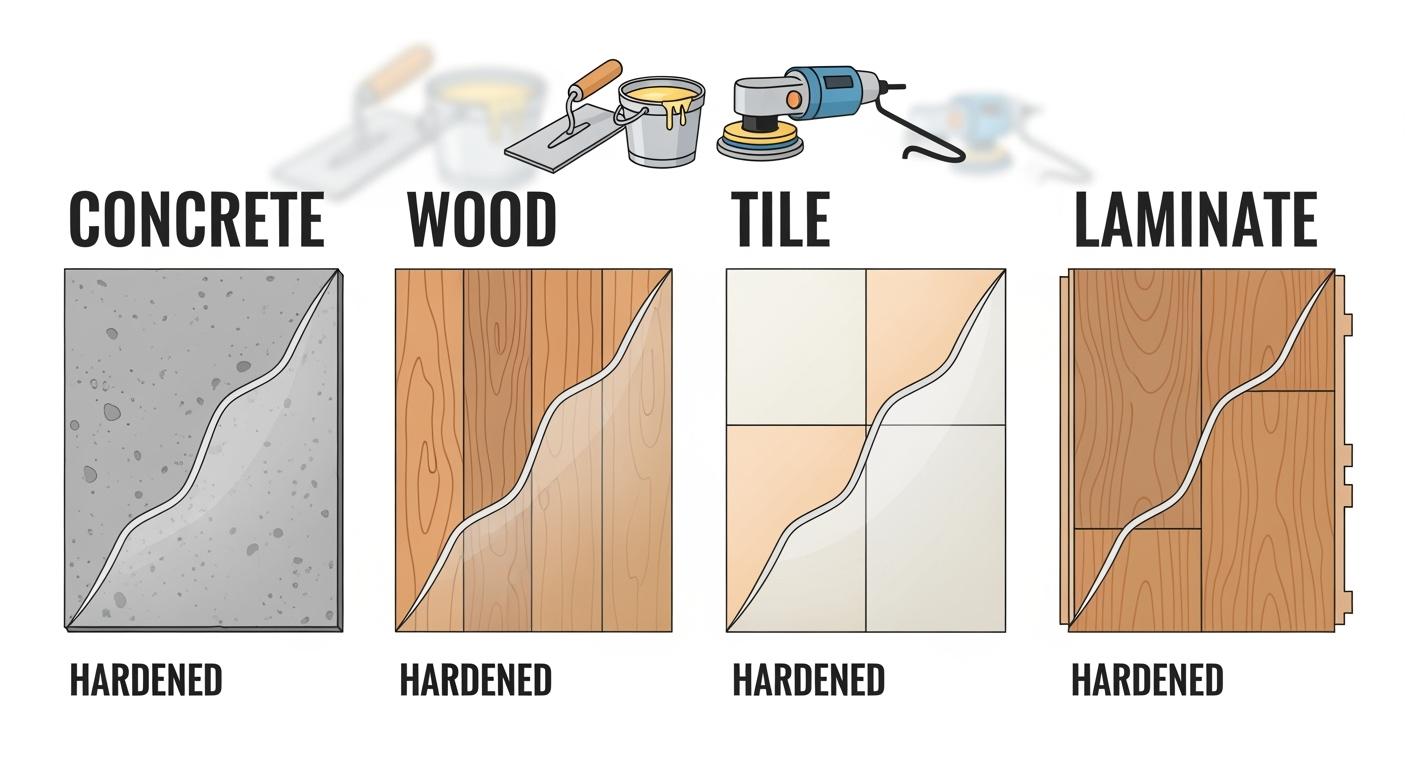

Different floors need different hardening methods. Concrete floors can use densifiers or epoxy coatings, while wood floors use polyurethane.

Choose a hardening method based on how you use the floor, your budget, and the look you want.

Understanding Floor Hardening

What is Floor Hardening

Floor hardening is a process that makes your floors tougher and more resilient. Think of it as giving your floor a super-suit. You apply special treatments or coatings to the surface. These treatments penetrate the floor material or form a protective layer on top. The goal is to boost the floor’s strength and resistance to damage. This process is crucial for extending the life of your flooring investment.

Key Benefits of Hardened Floors

Choosing floor hardening offers many advantages for your space. First, you get significantly increased wear resistance. Hardened floors can actually increase wear resistance up to three times compared to untreated concrete floors. This means your floors stand up better to daily foot traffic, heavy equipment, and general abrasion. Densification, for example, significantly reduces wear from abrasion in concrete floors.

Another major advantage is enhanced durability. You will find your floors resist scratches, impacts, and chemical spills much better. For instance, polyurethane flooring is known for its high resistance to wear and tear, impacts, and abrasion, providing high durability. This leads to less frequent repairs and lower maintenance costs over time. Hardened floors also offer maximum protection against staining and dust, making them easier to clean. They often look better too, with a smoother, more refined finish. These advantages make floor hardening a smart choice for long-lasting, attractive floors.

Chemical Densifiers

How Densifiers Work

You want a tougher floor, and chemical densifiers deliver. A penetrant chemical, or hardener, goes deep into your concrete. This hardener creates a chemical reaction within the concrete, aiding in hardening and dust-proofing. The concrete densifier penetrates the floor, making the surface less permeable and more abrasion resistant. It’s a fundamental change, unlike a surface-level epoxy.

Pros of Densifier Application

Densifiers offer clear advantages: increased surface hardness, abrasion resistance, and less dust. Your floors become easier to clean, cost-effective, and gain long-term durability. They strengthen concrete without a thick layer, unlike an epoxy, and are simpler than a full epoxy system.

Cons of Densifier Application

However, densifiers have disadvantages. They won’t fill cracks or add color. They primarily strengthen the existing surface. If you need a decorative finish or seamless look, an epoxy coating might be better. Densifiers aren’t for all substrates; you wouldn’t use them on a tile floor, for example.

Concrete Floor Densification

Concrete floors are ideal for densification. You’ll find liquid and dry shake forms. Liquid densifiers, like BANDě Concrete Densifier, penetrate to create that internal chemical reaction. Both improve concrete properties. For your concrete floor, densification enhances its life, often before other treatments like an epoxy.

Densifiers for Other Substrates

Densifiers excel on concrete, not other floor types. You wouldn’t apply a chemical densifier to wood or ceramic tile. These materials need different solutions. For tile, hardening is inherent. If installing tile, densifiers are for the concrete subfloor, not the tile itself. An epoxy coating, however, can go on various substrates, unlike densifiers. You might even use an epoxy over a densified concrete floor, or choose an epoxy instead of tile.

Epoxy Coating Solutions

How Epoxy Coatings Work

You might wonder how an epoxy coating transforms your floor. Epoxy reactions are step-wise polymerizations. This process needs two reactive groups, often called ‘A’ and ‘B’, to interact. In two-component epoxy systems, you keep these reactive groups separate. You mix them together, often through a nozzle, to start the curing process. For one-component systems, heat activates the reaction. This allows the components to react and cure. The result is a tough, durable epoxy layer.

Pros of Epoxy Coating

An epoxy coating offers many advantages. You get excellent chemical resistance, making it perfect for areas with spills. This type of epoxy flooring is also incredibly durable and resistant to heavy impacts. It is suitable for heavy loads, so you won’t worry about damage from equipment. These advantages make epoxy a top choice for demanding environments.

Cons of Epoxy Coating

However, an epoxy coating also has disadvantages. It can be slippery when wet, which you might need to address with anti-slip additives. The application process for epoxy flooring can be complex and requires careful preparation. Unlike a simple tile installation, you need specific conditions for proper curing.

Epoxy Flooring for Concrete

Epoxy flooring is especially effective for concrete surfaces. It bonds strongly with concrete, creating a seamless, protective layer. This epoxy coating seals the concrete, preventing dust and making it easy to clean. You can choose from various colors and finishes, giving your concrete floor a fresh look.

Epoxy for Garage Floors

For your garage, an epoxy coating is a fantastic choice. It protects against oil stains, tire marks, and abrasion. This epoxy flooring creates a bright, clean surface that is resistant to heavy impacts. You will find your garage floor much easier to maintain with an epoxy finish.

Commercial Epoxy Applications

Many commercial applications benefit from epoxy flooring. Its high resistance and durability make it ideal for warehouses, factories, and showrooms. This epoxy coating provides a hygienic, easy-to-clean surface. You will appreciate its long-lasting performance in high-traffic areas.

Polished Concrete Floors

Achieving Polished Concrete

You can transform your existing concrete slab into a beautiful, durable surface. Achieving polished concrete involves grinding and refining the surface. This process creates a smooth, glossy look. First, you clean the floor to remove dirt and buildup. Then, you grind the concrete to eliminate deep scratches. You then polish the surface to get your desired aesthetic, whether satin, semi-gloss, or high-gloss. This process includes surface smoothing. A densifier is applied to make the concrete denser and more resistant to wear. Finally, you seal the concrete, choosing a customized look like Matt-PLUS or High-Gloss.

Pros of Polished Concrete

Polished concrete offers many advantages. You get a highly durable and long-lasting floor. It’s also very low maintenance and easy to clean. You won’t need waxes or coatings, which saves you time. It’s an excellent choice if you need a floor suitable for heavy loads. You also get a professional finish that looks modern and sleek.

Cons of Polished Concrete

However, polished concrete also has its disadvantages. The initial installation cost can be higher than some other options. It’s a specialized process, so you need experienced professionals. It can also be cold and hard underfoot. If your concrete slab has significant cracks, they might show through the polished surface. It’s not like laying down a new tile floor where you can hide subfloor issues.

Polished Concrete for High-Traffic

For high-traffic areas, polished concrete is an excellent choice. Its durability and resistance to abrasion make it ideal for retail stores and warehouses. You will find it stands up well to constant foot traffic and heavy machinery. It’s a much more robust option than many types of tile. This provides a long-lasting solution.

Polished Concrete in Homes

You can also enjoy polished concrete in your home. It offers a contemporary and minimalist aesthetic. Many homeowners choose it for living areas, kitchens, and basements. It’s a unique alternative to traditional flooring like wood or tile. You get a seamless look without grout lines, unlike a ceramic tile. It’s a durable and stylish option. You won’t have to worry about loose tile. Think about the maintenance difference between polished concrete and a tile floor. It’s a different aesthetic than a ceramic tile. You can achieve a similar clean look to a large format tile. Consider the cost comparison to installing a new tile floor. This type of finish is distinct from any kind of tile.

Urethane Coatings

How Urethane Coatings Work

You might wonder how urethane coatings protect your floor. Urethane is a polymer that forms a tough, flexible film. It cures by reacting with moisture in the air or with a hardener. This creates a durable, seamless coating. Unlike a rigid epoxy, urethane offers more elasticity. This makes it less prone to cracking under impact. You will find it a different solution than a simple epoxy paint.

Pros of Urethane Coatings

Urethane coatings offer many benefits. You get excellent abrasion resistance and impact protection. They also provide good chemical resistance. For example, polyurethane coatings remain unaffected by cyclohexane. While some formulations might show slight deterioration from acetone or isopropyl alcohol, their overall chemical resistance is strong. You will find this coating more flexible than an epoxy, which helps prevent chips. This type of coating also offers a beautiful, long-lasting finish. It’s often preferred over an epoxy for its flexibility.

Cons of Urethane Coatings

However, urethane coatings do have some disadvantages. The application process can be sensitive to humidity and temperature. This makes it trickier to install than simply laying down a tile. It also has a strong odor during application. You might find it more expensive than a basic epoxy system. It’s not as thick as some heavy-duty epoxy options.

Urethane for Industrial Use

Urethane is a top choice for industrial applications. Its high resistance to chemicals and heavy traffic makes it ideal for warehouses and manufacturing plants. This coating can withstand forklifts and machinery better than many types of tile. You can even apply it over an existing epoxy floor for added protection. This creates a robust, multi-layered epoxy system.

Urethane for Decorative Finishes

You can also use urethane for decorative finishes. It provides a clear, glossy, or matte finish that enhances the floor’s appearance. This coating offers a different aesthetic than a traditional tile floor. It gives you a seamless look, unlike individual tile pieces. You can achieve a high-end look without the grout lines you get with tile. It’s a versatile option, often used as a topcoat over an epoxy system. This final epoxy layer looks great. You won’t have to worry about loose tile.

Other Floor Hardening Options

Polyurethane Finishes for Wood

You want to protect your beautiful wood floors. Polyurethane finishes are an excellent choice. They create a clear, durable layer over the wood. You will find them easy to apply. Many types dry quickly, letting you use your floor sooner. These finishes offer good resistance to scratches and scuffs. They also make cleaning your wood floors simple. Unlike a ceramic tile, wood needs this protective layer. You get a warm, natural look, which is different from a cold concrete or an epoxy floor. This finish helps your wood last longer.

Acrylic Sealers for Light Duty

For areas with less traffic, acrylic sealers are a good option. You can use them on concrete or even some natural stone. They provide a protective barrier against stains and light abrasion. These sealers are easy to apply and dry fast. They offer a cost-effective way to enhance your floor’s appearance. You might choose an acrylic sealer for a patio or a basement floor. It gives a nice finish without the heavy-duty protection of an epoxy. It is also much simpler than installing a new tile floor.

Penetrating Sealers for Stone

Natural stone floors, like granite or marble, need special care. You should use penetrating sealers for these surfaces. These sealers soak into the stone, protecting it from within. They guard against moisture and stains without changing the stone’s natural look. You won’t get a glossy finish like an epoxy, but you preserve the stone’s unique beauty. This is different from laying down a protective tile. You maintain the original stone, unlike replacing it with a new tile. This sealer helps prevent etching and discoloration. It is a vital step for stone maintenance. You will find it keeps your stone looking great. It is not like an epoxy that sits on top. You protect the stone itself.

Choosing Your Floor Hardening Method

You have explored many floor hardening options. Now, you need to decide which one suits your needs best. This choice depends on several key factors. You want to make an informed decision for your investment.

Traffic, Usage, and Activity Type

Think about how you will use your floor. Will it see light foot traffic, or will heavy machinery roll over it daily? The level of traffic and the type of activity directly influence the best floor hardening method. For example, a residential basement needs different protection than a busy warehouse.

Consider these categories for your floor’s usage:

Application Type | Recommended Consumption (kg/m²) |

|---|---|

Light duty | 3 |

Medium duty | 5 |

Heavy duty | 7 |

For areas with heavy or frequent traffic and high impact, like engineering workshops and warehouses, products such as Deltahard MT are excellent choices. You need a solution that can withstand constant wear. An epoxy coating or robust epoxy flooring often provides the necessary durability for these demanding environments. If you expect heavy machinery, you need a solution that offers superior impact resistance.

Budget and Long-Term Maintenance

Your budget plays a big role in your decision. You need to consider both the initial cost of application and the long-term maintenance expenses. Some floor hardening methods, like a basic acrylic sealer, have a lower upfront cost. However, they might require more frequent reapplication. Others, such as a full epoxy flooring system or polished concrete, have a higher initial cost. They often offer superior durability and lower maintenance over many years. You save money on repairs and cleaning in the long run. Always weigh the initial investment against the total cost of ownership. You want a solution that fits your financial plan and provides lasting value.

Desired Aesthetic and Surface Effect

You also need to think about how you want your floor to look. Do you prefer a natural, subtle appearance, or a vibrant, glossy finish? Different floor hardening methods offer various aesthetic outcomes. For instance, Sikafloor® CureHard-24 provides a clear liquid finish, maintaining the natural look of your concrete. On the other hand, 4EVER CONCRETE FLOOR products offer a wide variety of color options. You can achieve a specific look, but remember that actual colors may vary depending on monitor settings and floor conditions. These conditions can also affect the final finish and luster. High weather resistance white is exclusively available for the CONCRETE FLOOR COATING SERIES adhesion. Toning products and EBFs require a minimum order of 10 sets of the same color, and the 1kg set is only available in green. You can achieve a professional finish that matches your design vision.

Matching Method to Floor Material

You must match the hardening method to your floor’s material. Not all treatments work on every surface. For concrete floors, you have many options: chemical densifiers, epoxy coating, polished concrete, or urethane coatings. Each offers unique benefits. For wood floors, polyurethane finishes are typically your best bet. They protect the wood while enhancing its natural beauty. You would not use a concrete densifier on a wood floor. Similarly, natural stone benefits from penetrating sealers that protect without altering its appearance. You need to choose a method compatible with your existing floor material to ensure proper adhesion and durability.

Hardening for Tile Installation Substrates

When you plan a tile installation, the subfloor preparation is critical. You want a stable, durable base for your tile. For floor hardener application on concrete floors, the surface must be thoroughly cleaned of dirt, dust, and other foreign matter prior to application. This ensures proper bonding. You can use a chemical densifier on the concrete subfloor to increase its hardness and reduce dusting before you begin your tile installation. This step enhances the overall durability of your flooring system.

You might also consider an epoxy coating as part of your subfloor preparation. An epoxy can create a smooth, level surface, which is essential for high-accuracy tile setting. This helps you achieve perfect alignment for your tile. A well-prepared subfloor with an epoxy layer provides excellent holding power for the tile adhesive. This reduces the risk of loose or cracked tile later on. You want to avoid tile misalignment and ensure a flawless finish. Proper subfloor hardening contributes to a quick and thorough installation. It also leads to less tile damage during and after the process. The accuracy of your tile layout depends heavily on the quality of the subfloor. An epoxy solution can significantly improve this accuracy.

You now understand floor hardening offers great benefits. The best method truly depends on your specific floor, its use, and your priorities. Always consider durability, appearance, cost, application time, and long-term maintenance. Carefully assess your needs. Consult flooring professionals for an informed decision. This ensures lasting satisfaction and floor protection.

FAQ

Can I use floor hardening on existing tile?

You don’t harden existing tile. Tile is already hard. You harden the subfloor before tile installation. This creates a strong base for your tile. This helps your tile last longer.

Does floor hardening protect my tile from all damage?

Floor hardening protects the subfloor, not the tile directly. It prevents issues that could damage your tile from below. Your tile still needs proper care.

What if I want to change my tile later?

Hardening the subfloor won’t stop you from changing your tile. It provides a durable base. You can remove old tile and install new tile easily. This makes future tile projects simpler.

See Also

Comparing Industrial Floor Hardeners: Your Definitive Guide for 2025

Selecting The Best: Top Five Concrete Floor Hardeners For Industry

Understanding Concrete Floor Hardeners: Their Purpose And Functional Mechanics

The 2025 Handbook: Choosing The Ideal Concrete Floor Hardener

UK Floor Hardeners: Optimal Solutions For Industrial Warehouse Environments