Untreated concrete floors frequently suffer from dusting, abrasion, and rapid deterioration. Crystal hardeners offer a revolutionary solution, enhancing durability and simplifying maintenance. This technology meets the demand for resilient concrete surfaces; the concrete hardener market projects a 7.2% CAGR through 2032. It stands as a key floor technology for 2025, transforming expectations beyond simple comparisons like crystal floor hardener vs epoxy.

Key Takeaways

Crystal floor hardeners make concrete floors much stronger. They stop dusting and make floors last longer.

These hardeners work by a chemical reaction. They fill tiny holes in the concrete, making it harder and more resistant to damage.

Crystal hardeners are better than epoxy coatings. They offer a permanent solution and save money over time.

What Are Chemical Floor Hardeners and How They Work

Defining Crystal Concrete Hardeners

Crystal concrete hardeners are liquid chemical solutions. People also call them concrete densifiers. These solutions penetrate concrete surfaces. They work by reacting with the concrete itself. Typical crystal concrete hardeners, specifically silicate-based densifiers, contain potassium or sodium silicate compounds. These compounds have silicon (Si), oxygen (O), and other elements. They are small molecular compounds. You can find premium lithium-based silicates or more economical sodium-based silicates. First-generation densifiers use magnesium, potassium, and sodium silicate. Second-generation densifiers use lithium silicate-based densifiers with nano-sized technology and waterborne colloidal silica from nano-sized particles. Many companies offer these chemical floor hardeners. For example, specific products categorized as Concrete Densifiers & Hardeners include BELLATRIX, CURE-TREAT RTU, LIQUI-HARD, and LIQUI-HARD ULTRA. LIQUI-HARD is a good example of a concrete liquid hardener. It is a proprietary, water-based, ready-to-use, clear silicate liquid. Manufacturers formulate it with chemically reactive raw materials to harden and dustproof concrete. This waterborne solution improves abrasion and chemical resistance. It significantly enhances the durability of the concrete surface. These floor hardener chemicals are vital for modern construction. Applying these chemical floor hardeners makes a big difference.

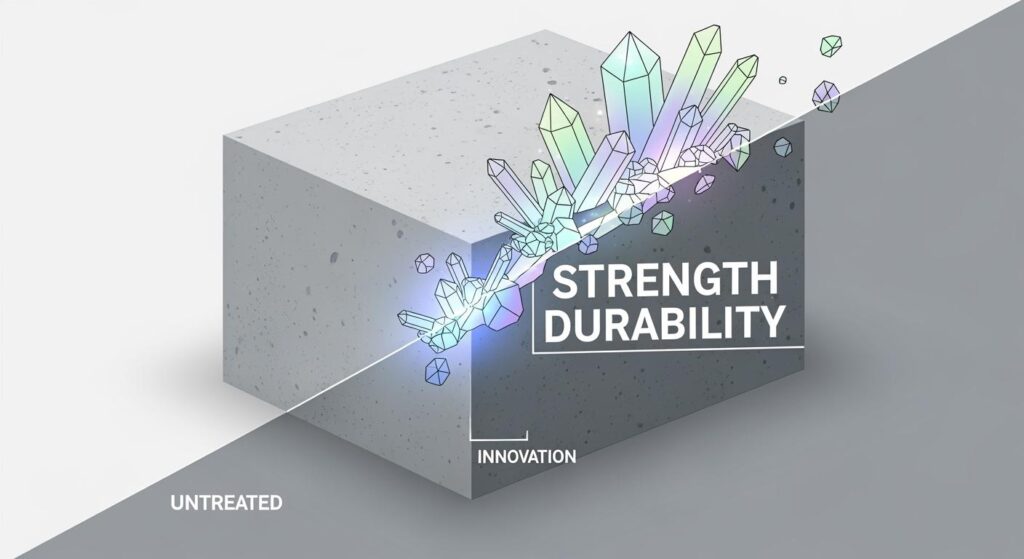

The Science of Concrete Transformation

These chemical floor hardeners work through a fascinating chemical reaction. When they penetrate the concrete, the silica they contain reacts with calcium hydroxide. Calcium hydroxide is a byproduct of cement hydration. This reaction forms calcium silicate hydrate (C-S-H). This process creates more C-S-H phases, also known as gel, within the concrete’s pore space. This gel reduces porosity. It strengthens the concrete structure and enhances the surface’s resilience. Silicate-based liquid floor hardeners chemically react with calcium hydroxide. This byproduct of cement hydration forms C-S-H gels. These gels are a desired component in concrete. They fill calcium hydroxide-saturated bleed water channels and voids. This reaction helps to increase surface density, strength, and long-term resilience for the concrete. Endurable Concrete Hardener, for instance, has nearly 100% pure silica. It penetrates concrete because of its low surface tension. The silica then reacts with the unreacted calcium hydroxide in the concrete. This forms calcium silicate hydrate. While calcium silicate hydrate forms during the initial concrete curing process when wet, its formation stops once the concrete dries. This leaves unreacted calcium hydroxide (lime) on the surface. The hardener acts like a ‘second component.’ It is similar to how a second part completes an epoxy. It starts this chemical reaction. This results in harder and more abrasion-resistant concrete. This process helps to improve surface hardness. These concrete hardeners are essential for long-lasting results. Many chemical floor hardeners rely on this science.

Silicate and Collooidal Silica Technologies

When considering floor hardener chemicals, you typically encounter two main technologies: silicate binders and colloidal silica. Silicate binders are soluble alkali metal silicates, often called ‘water glass.’ Colloidal silica, on the other hand, consists of nano-sized amorphous silica particles (SiO2). These particles are incredibly small, typically ranging from 4 to 22 nm, though they can be 5-100 nm. Silicate binders are soluble, so they do not have a specified particle size. Colloidal silica boasts a high surface area, up to 350 m²/g, which is not applicable to soluble silicates.

Colloidal silica offers specific advantages over traditional silicate hardeners. Its particles are significantly smaller, typically 5 to 50 nm. This allows for much deeper penetration into concrete pores. Colloidal silica particles can also form bonds with other silica particles. This further increases concrete density and strength, a capability not present in silicate densifiers. Another key benefit is that colloidal silica densifiers do not leave mineral salt deposits on the surface. This eliminates the need for post-application cleaning and prevents discoloration. The small, spherical nature of colloidal silica particles results in a very high surface area. This maximizes bonding sites for reaction with calcium hydroxide and increases densification efficiency. These liquid hardeners truly transform the concrete floor. Many chemical floor hardeners now use these advanced technologies. A good concrete hardener makes a significant difference. These floor hardener chemicals are changing the game.

Transforming Concrete Floors: Benefits and Comparisons

Durability and Performance for Concrete Floors

Crystal floor hardeners fundamentally change concrete, making it much tougher. They deliver exceptional durability and performance. These advanced solutions significantly increase abrasion resistance. Concrete floors treated with crystal hardeners show an increase in abrasion resistance to approximately 6.4. This improvement happens as the various components within the concrete cure into a hardened entity. This means floors can withstand heavy traffic, machinery, and daily wear without showing damage. The hardening process also makes the floor dustproof. It locks in salts, keeping floors clean and preventing dust from settling on goods and machinery. This creates a healthier and safer environment. The result is enhanced strength and a longer-lasting surface. A high-quality concrete hardener provides superior abrasion resistance, making it ideal for demanding environments.

Aesthetic Appeal and Maintenance Advantages

Beyond strength, crystal hardeners also boost the aesthetic appeal of concrete. They create a natural crystal luster. Floors become brighter with use, reducing the need for waxing or polishing. This natural sheen improves the overall look of any space. These solutions also offer significant maintenance advantages. They are a cost-effective solution, requiring only one permanent application for lifetime protection. This reduces the need for costly re-application of coatings. It eliminates downtime for coating removal and re-installation. It also minimizes ongoing maintenance expenses.

Consider these benefits:

Dustproofing: Crystal hardeners fill microscopic pores, preventing dust.

Stain Resistance: A less porous surface resists stains better.

Low Maintenance: This saves time and money.

Reduced Cleaning Costs: Coated surfaces are easier to clean.

Protection: Coatings protect against wear from salts, oils, water, and chemicals.

Energy Savings: Coated surfaces reflect more light, potentially lowering electricity bills.

Many crystal hardeners are eco-friendly and safe. They are water-based, non-toxic, and quick-drying. They meet strict environmental standards. For example, many products have an Environmental Product Declaration (EPD) in accordance with EN 15804. They are independently verified by Institut für Bauen und Umwelt e.V. (IBU). They are USDA approved and comply with all Federal and State VOC requirements. Some even have Health Product Declarations (HPD) and CDPH VOC Emissions Certificates.

You can find these hardeners in many places. They are perfect for factory floors, schools, hospitals, supermarkets, underground garages, and exhibition halls. A factory-grade floor hardener ensures maximum protection in industrial settings. The ease of application makes them a popular choice.

Crystal Floor Hardener vs. Epoxy: A Superior Choice

When comparing a crystal floor hardener vs epoxy, crystal hardeners often emerge as the superior choice for long-term value. Epoxy coatings typically last around 5-10 years. Their durability depends on wear and exposure to harsh conditions. However, a crystal hardener offers a permanent solution. It becomes an integral part of the concrete itself. This means no peeling, chipping, or delamination, common issues with epoxy.

The initial application of a crystal hardener creates a permanent bond. This eliminates the need for future re-applications. This makes the crystal floor hardener vs epoxy debate clear for many. Polished concrete floors, treated with a hardener, are up to six times less expensive than VCT or epoxy coating over their lifespan. This long-lasting, low-maintenance floor results in significant short-term and long-term cost savings. The hardener transforms the concrete, providing a permanent, durable, and aesthetically pleasing floor. This makes the crystal floor hardener vs epoxy comparison lean heavily towards the hardener for many applications.

Crystal hardeners effectively solve common concrete problems, offering long-term value. They shape the future of concrete floor surfaces, highlighting sustainability, cost-effectiveness, and superior performance. This hardener is an indispensable technology for modern construction in 2025 and beyond.

FAQ

What makes crystal floor hardeners different from regular concrete sealers?

Crystal hardeners chemically react with concrete. They form dense, permanent crystal structures. Sealers just sit on the surface. This makes hardeners much more durable and long-lasting.

How long does a crystal floor hardener last?

Crystal floor hardeners offer a permanent solution. They become an integral part of the concrete. This means they do not peel or chip like coatings. They provide lifetime protection.

Can crystal hardeners be used in homes, or are they just for industrial spaces?

Crystal hardeners work well in many settings. They are great for industrial spaces, schools, and hospitals. They also enhance durability and appearance in residential garages or basements.

See Also

Maximize Concrete Longevity: A 2025 Guide to Floor Hardener Application

Understanding Liquid Concrete Hardeners: Sealing and Densifying for Durability

Choosing the Optimal Concrete Floor Hardener: Your 2025 Selection Guide

Demystifying Concrete Floor Hardeners: Their Purpose and Operational Mechanics

Unveiling the Science: How Concrete Surface Hardeners Achieve Their Effects