Choosing your floor finish is tough. You often face a dilemma: crystal floor hardener or an epoxy coating. The “better” choice for your floor isn’t universal. It depends on your needs, budget, and how you use your floor. This article clearly compares these options, including epoxy floor paint. We help you pick the best epoxy for your floor, considering various coatings.

Key Takeaways

Crystal floor hardener makes concrete stronger from the inside. It is good for places needing high strength and low cost, like warehouses.

Epoxy coating puts a tough layer on top of the floor. It offers many colors and protects against chemicals, making it good for kitchens or garages.

Choose between them based on what you need: a natural, strong concrete look (hardener) or a colorful, protective surface (epoxy).

Understanding Crystal Floor Hardener

What is Crystal Floor Hardener?

You might wonder, “What exactly is a crystal floor hardener?” It’s not a coating that sits on your floor’s surface. Instead, you apply this liquid solution directly to concrete. It penetrates the surface to chemically react with the concrete itself. These hardeners often contain metallic and non-metallic aggregates, activating chemicals, and selected Portland cements. They enhance the concrete’s inherent properties.

How Crystal Floor Hardener Works

When you apply a chemical hardener, reactive raw materials penetrate your concrete floor. A chemical reaction then occurs, creating a byproduct that fills tiny pores within the concrete. This makes your concrete surface much denser. It significantly enhances the durability and strength of your floor. This treatment also improves abrasion and chemical resistance, solidifying the concrete and stopping dusting. This boosts your floor’s overall performance.

Benefits for Your Floor

A hardener offers many benefits for your floor. You’ll see a substantial increase in durability. For example, Mohs hardness can reach 8-9, an increase of about 45%, or even 200%. This improved strength also means better impact resistance. Compressive strength can be 25% higher. Your floor will gain better chemical resistance and stand up to high traffic. These enhanced properties make your floor more resilient, handling heavy traffic and impact better.

Limitations and Considerations

While a hardener offers great durability, it has limitations. It doesn’t add color or a decorative finish like an epoxy coating. Your floor’s appearance remains natural concrete. It also doesn’t offer the same moisture resistance as some coatings, which might be crucial for certain residential floors. For residential spaces, you might prefer an epoxy coating’s aesthetics. Its internal adhesion differs from a surface coating, which relies on external adhesion for its bond.

Ideal Applications for Your Floor

A crystal floor hardener is perfect for areas needing extreme durability and strength. Think industrial warehouses, factories, and retail spaces with high traffic areas. It’s excellent for floors experiencing heavy impact or requiring superior abrasion resistance. If you need a long-lasting, low-maintenance floor that withstands tough conditions and high traffic, this is your solution. It enhances concrete’s natural properties without a thick coating, offering great impact properties, unlike a purely decorative epoxy.

Understanding Epoxy Coating

What is Epoxy Coating?

You might ask, “What exactly is an epoxy coating?” It’s a tough, protective coating you apply to your floor. This isn’t just a paint; it’s a two-part system. You mix an epoxy resin with a hardener. The epoxy resin often comes from bisphenol A (Bis A) or bisphenol F (Bis F). The hardener usually contains amines or amides. When you combine these, they create a strong, durable epoxy floor coating. This epoxy resin application forms a powerful bond with your floor’s surface. Many different epoxy coatings exist, each with unique properties.

How Epoxy Coating Works

When you mix the epoxy resin and hardener, a chemical reaction starts. This process, called polymerization, creates a tightly cross-linked polymer structure. This transforms the liquid epoxy resin into a solid, rigid material. This chemical reaction forms covalent bonds between epoxy molecules. It builds a three-dimensional network of interconnected polymer chains. This gives your epoxy floor coating its superior strength and durability. This protective coating adheres strongly to your floor, offering excellent performance.

Benefits of Epoxy for Your Floor

An epoxy floor coating offers many benefits for your floor. You get exceptional durability and strength. This epoxy floor paint provides excellent impact resistance. Your epoxy floor can withstand high traffic. For example, a properly installed epoxy floor in a manufacturing warehouse can last 10-15+ years. This makes it a long-lasting solution for your floor. The seamless finish also makes cleaning easy, improving the overall performance of your floor. This coating enhances your floor’s properties significantly.

Epoxy Coating Limitations and Considerations

While epoxy offers great properties, you must consider some limitations. Proper surface preparation is critical for good adhesion. If you skip or rush this step, your epoxy floor paint might delaminate or bubble. The concrete surface needs to be clean, dry, and free of contaminants for proper adhesion. Moisture is a major cause of epoxy failure. You must test your floor for moisture before applying the epoxy resin. Temperature and humidity also significantly impact curing times for your epoxy floor paint. Poor adhesion can compromise the entire coating.

Ideal Applications for Epoxy Floors

Epoxy flooring is perfect for many demanding environments. You often see this epoxy floor paint in commercial kitchens and food production facilities. Automotive garages also frequently use epoxy floor paint. Its high traffic and impact resistance make it ideal for industrial settings. You can also use epoxy floor paint in residential garages or basements where you need a durable, easy-to-clean floor. This epoxy coating provides excellent chemical resistance and moisture resistance, ensuring long-term performance for your floor. These epoxy coatings offer great impact properties.

Crystal Floor Hardener vs. Epoxy: A Direct Comparison

When you choose a finish for your floor, you need to weigh many factors. Let’s directly compare crystal floor hardener and epoxy across key areas. This will help you decide which is best for your specific needs.

Durability and Wear Resistance for Your Floor

Both crystal floor hardener and epoxy offer excellent durability, but they achieve it differently. A crystal floor hardener works by making your concrete floor denser and stronger from within. This significantly boosts its inherent strength and abrasion resistance. You get a floor that stands up to heavy use.

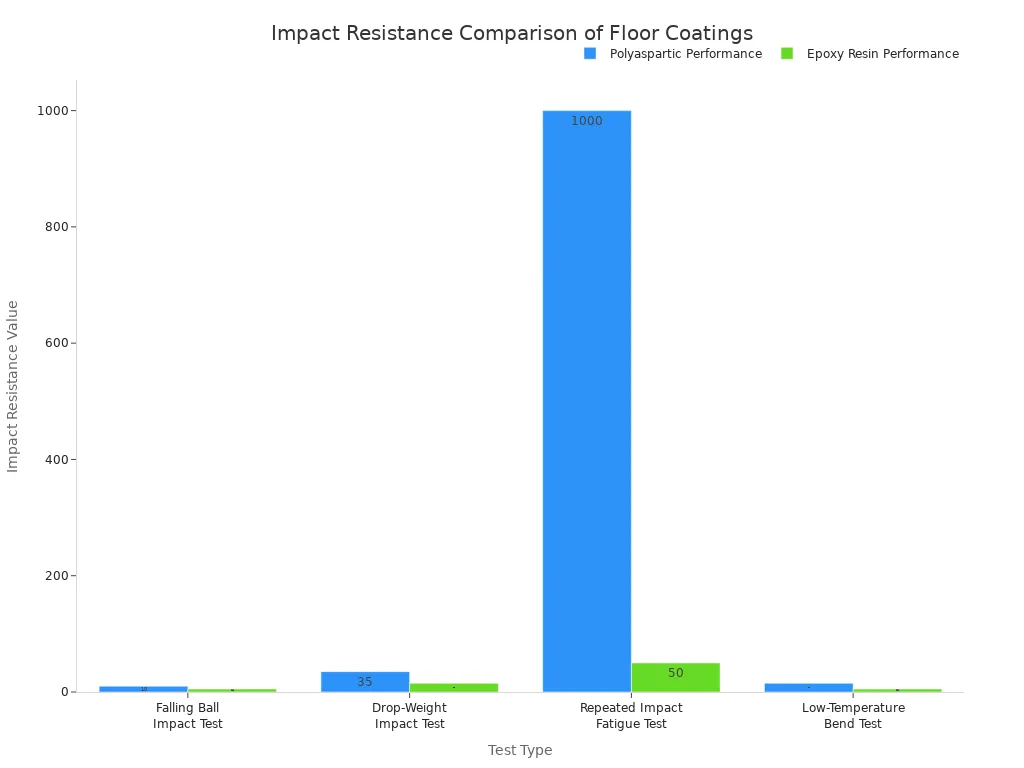

Epoxy, on the other hand, creates a tough, protective layer on top of your existing floor. This epoxy resin forms a robust coating that resists wear. While both are durable, you might find differences in how they handle specific types of stress. For instance, when you look at impact resistance, some advanced coatings often compared to epoxy, like polyaspartic, show superior performance.

Standard | Polyaspartic Performance | Epoxy Resin Performance | |

|---|---|---|---|

Falling Ball Impact Test (Normal Impact) | ASTM D2794 | Critical failure energy determined; 1 kg steel ball dropped from 1m is ~10 J | Not specified, but implied to be less resistant than polyaspartic |

Drop-Weight Impact Test (Controllable Energy Impact) | ASTM D7136, EN 13596 | Ultimate failure energy ≥ 35 J (for 2mm thick coating); Energy absorption ratio > 85% | Energy absorption ratio < 40% |

Repeated Impact Fatigue Test | N/A | After 1000 impacts (1 kg steel ball from 0.5m), dent depth < 0.8 mm, no delamination | Cracks after ~50 impacts |

Low-Temperature Bend Test after Impact | ASTM D522 (bend) | No cracking after 15 J impact at -40 °C followed by 180° bend | Fractures into pieces after low-temperature impact plus bending |

This chart shows that while epoxy resin provides good protection, other advanced coatings can offer even better impact properties. A crystal floor hardener improves the concrete’s natural properties, making it very resilient to impact and abrasion.

Appearance and Aesthetic Options for Your Floor

When it comes to looks, epoxy offers you a world of choices. Epoxy floors give you extensive design flexibility. You can choose any color, add symbolic striping, or even embed mosaics. You can highlight safety zones. This epoxy resin application allows for metallic, quartz, or flake enhancements. Beyond durability, epoxy floors provide impressive versatility in design. You have limitless color options and finishes, from a subtle matte to a glass-like gloss. You can also integrate safety striping or corporate logos into your epoxy floor paint.

Epoxy coatings are known for their versatility, offering:

Multiple colors and finishes for customization.

Protection against stains, chemicals, and high traffic.

Options for a smooth, glossy finish or a rough anti-slip finish.

A wide range of colors and decorative options, including solid colors, metallic finishes, or decorative flakes.

A crystal floor hardener, however, maintains the natural look of your concrete floor. It enhances the concrete’s inherent properties but does not add color or a decorative layer. If you prefer a raw, industrial aesthetic, this might be perfect for your floor. If you want a vibrant, customized look, an epoxy floor coating is your go-to.

Maintenance and Cleaning for Your Floor

Both options offer relatively low maintenance, but with slight differences. A crystal floor hardener makes your concrete surface denser, which reduces dusting and makes cleaning easier. You typically just need regular sweeping and occasional wet mopping.

Epoxy floors are also easy to maintain because they create a seamless finish. This means no grout lines or cracks for dirt to hide in. You can easily wipe spills away. Here’s a look at typical annual maintenance costs for an epoxy floor coating in a manufacturing facility:

Maintenance Task | Annual Cost Range (per 10,000 sq ft) |

|---|---|

Regular cleaning | $800 – $1,200 |

Periodic deep cleaning | $500 – $1,000 |

Minor repairs | $200 – $500 |

Total Annual Cost | $1,500 – $2,700 |

Epoxy floors are recognized for their ease of maintenance, typically requiring only regular cleaning. In contrast, traditional flooring options like VCT may incur additional annual maintenance expenses, potentially adding several thousand dollars to the budget due to periodic stripping and waxing. This shows the long-term value of an epoxy floor paint.

Cost Analysis: Material and Installation for Your Floor

The cost of your floor project depends on materials and installation. For a solid-color epoxy floor, the material cost is approximately $2 per square foot. You can expect an additional $2 to $4 per square foot for installation labor. The estimated cost to epoxy coat a garage floor, which is a standard epoxy floor coating system, starts at $7.74 to $12.60 per square foot as of October 2025.

Epoxy Type | Cost per Square Foot |

|---|---|

Solid Color Epoxy | $3 – $7 |

A crystal floor hardener generally has a lower material cost per square foot than an epoxy coating. Its installation process can also be less labor-intensive, potentially reducing overall costs. However, complex epoxy coatings with decorative flakes or metallic effects will naturally cost more than a basic epoxy floor paint.

Installation Process and Time for Your Floor

The installation process differs significantly. For a crystal floor hardener, you apply a liquid solution to your concrete surface. It penetrates and reacts with the concrete. A floor treated with Concrete Binder & Hardener, a type of hardener, can accept foot traffic and light vehicle traffic after 12 hours. This curing time assumes a temperature of 60-70°F and good ventilation. Full cure is achieved after 24 hours. This means you can quickly return your floor to service.

Installing an epoxy floor coating involves more steps. You must prepare the surface thoroughly, which includes cleaning, grinding, and sometimes repairing cracks. Then, you apply multiple layers of epoxy resin, each requiring specific drying times. This multi-step process means an epoxy floor paint installation takes longer, often several days, before you can use the floor for high traffic.

Chemical and Stain Resistance for Your Floor

Both options offer good chemical resistance, but their properties vary. A crystal floor hardener improves the concrete’s natural resistance to many chemicals and oils by making the surface denser. This helps prevent absorption and staining.

An epoxy floor coating creates a non-porous barrier on your floor. This makes it highly resistant to a wide range of chemicals, oils, and stains. However, some substances can still cause issues if not cleaned promptly.

Consider these potential issues for an epoxy floor coating:

Motor Oil: Can cause surface stains if not promptly cleaned, despite high resistance.

Brake Fluid: Requires prompt cleanup to prevent potential damage, despite excellent resistance.

Gasoline: Spills should be wiped up immediately to prevent staining and maintain appearance.

Harsh Cleaning Agents: Such as bleach or ammonia-based cleaners, can damage epoxy coatings if used improperly.

More aggressive chemicals can also pose a threat to your epoxy floor paint:

Strong acids

Harsh alkalis

Industrial solvents (e.g., paint strippers)

Battery acid

Harsh cleaning agents (e.g., concentrated bleach, ammonia)

You should always clean spills quickly on an epoxy floor to maintain its performance and appearance.

Making Your Decision: Which is Right for Your Floor?

You have explored the details of both crystal floor hardener and epoxy. Now, you need to decide which one best suits your floor. This choice depends on your specific needs, budget, and the environment where you will apply the coating.

When to Choose Crystal Floor Hardener

You should choose a crystal floor hardener when you prioritize enhancing the natural properties of your concrete floor. This option is incredibly cost-effective. You will find a low initial investment cost and low maintenance costs. A crystal floor hardener also offers a long lifespan, often more than 10 years. It is easy to clean, and it can even save energy by increasing ambient light reflection.

Consider a crystal floor hardener if your existing concrete is in good condition. The application process involves several steps to achieve a durable, lustrous finish:

You start by using metal bond diamonds to remove existing epoxy coatings, surface stains, and blemishes.

Then, diamond grinding pads prepare the porous surface of your concrete.

You apply a Crystal L Densifier liquid hardener to the concrete, which seals and strengthens the surface.

Resin-bonded diamonds polish the concrete in stages, making the surface smoother and more refined with each step.

An ultra-fine diamond pad brings your concrete to a beautiful, durable luster.

Finally, you burnish it with Crystal Sheen to get the highest lusting effect.

This process effectively removes common issues like glue, paint, shadows, and stains. Furthermore, if you need a floor that breathes, a crystal floor hardener is an excellent choice. Densified concrete remains breathable. The altered pore structure stops the passage of minerals that cause efflorescence on the surface. This means your floor maintains breathability while preventing mineral passage, which is beneficial for facilities requiring high breathability of the concrete slab.

When to Choose Epoxy Coating

You should opt for an epoxy coating when you need a highly customizable, aesthetically pleasing, and extremely protective surface for your floor. Epoxy is perfect for environments demanding strict hygiene or specific visual requirements.

For example, many commercial spaces benefit greatly from an epoxy floor coating:

Retail Sector (e.g., boutiques, car showrooms): Epoxy solutions are tailored for aesthetic appeal and durability. They withstand heavy foot traffic while providing a visually captivating surface that aligns with your branding.

Healthcare Facilities (e.g., hospitals, clinics, labs): Seamless epoxy floor coatings minimize dirt and bacteria accumulation. They offer an easily sanitized surface, which is essential for hygiene.

Food & Beverage Production: Epoxy floor coatings are easy to clean, resist bacterial growth, and can withstand acidic or alkaline spills. This is crucial for compliance with health standards.

Epoxy flooring contributes to enhanced hygiene by providing seamless, non-porous, and easy-to-clean surfaces. These surfaces prevent the growth of bacteria and ensure a sterile environment. This is particularly vital in industries where maintaining stringent sanitary conditions is paramount for the well-being of individuals.

You might also need an epoxy floor paint to meet specific safety regulations or industry standards. OSHA standards often require epoxy flooring in industrial settings to reduce hazards like slips, trips, and falls. This often necessitates anti-slip additives or coatings. Compliance also extends to chemical resistance to withstand harsh substances. OSHA Regulation 1910.22 mandates that all places of employment must be clean, orderly, sanitary, have dry floors, and be free from hazards. An epoxy floor paint supports this by forming a seamless, easy-to-clean barrier that prevents bacteria and reduces tripping hazards.

Factors to Consider for Your Floor

When making your decision, you need to consider several key factors for your floor:

Moisture Levels: You must assess the moisture vapor transmission rate (MVTR) of your concrete slab. For the ASTM F1869 calcium chloride test, a moisture vapor transmission rate exceeding 3 lbs/1,000 sq ft/24 hours necessitates a vapor barrier before applying an epoxy resin. For the ASTM F2170 in-situ probe test, a relative humidity in the slab exceeding 75% requires a vapor barrier. Most epoxy floor coating manufacturers specify limits, often requiring RH levels below 75–85% to be considered safe without a moisture vapor barrier.

Traffic and Impact: How much foot traffic or heavy machinery will your floor endure? Both options offer good durability, but their impact resistance differs.

Aesthetics: Do you want a natural concrete look, or do you prefer a wide range of colors and decorative options? An epoxy floor paint offers extensive design flexibility.

Budget: Your budget will influence your choice. Crystal floor hardener generally has a lower initial cost. However, the long-term durability and low maintenance of an epoxy floor coating can offer significant value.

Installation Time: How quickly do you need your floor ready for use? Crystal floor hardener has a faster return-to-service time. An epoxy resin application takes longer due to multiple layers and curing times.

Chemical Exposure: Will your floor be exposed to harsh chemicals? An epoxy coating provides a superior non-porous barrier against many substances.

Considering Other Floor Coatings: Beyond Epoxy (e.g., Polyurea, Polyaspartic, Acrylic vs. Epoxy Floor Coating)

While epoxy is a popular choice, you have other advanced coating options for your floor. These include polyurea, polyaspartic, and acrylic coatings. Each offers unique benefits that might better suit your specific needs.

Let’s look at how polyurea compares to epoxy:

Feature | Epoxy | Polyurea |

|---|---|---|

Flexibility | Less flexible, can crack or chip under impact or substrate movement. | Highly flexible, can withstand significant movement and impact without cracking. |

Cure Time | Longer cure time (24-72 hours for light traffic, 7 days for full cure). | Much faster cure time (can be walked on in hours, full cure in 24 hours). |

Durability | Good abrasion and chemical resistance, but can yellow over time with UV exposure. | Excellent abrasion, chemical, and UV resistance; maintains clarity and color. |

Application Temperature | More sensitive to temperature and humidity during application. | Wider application temperature range, more forgiving in varying conditions. |

Adhesion | Excellent adhesion to concrete. | Excellent adhesion to concrete, often better than epoxy. |

VOCs | Can have higher VOCs (Volatile Organic Compounds) depending on the product. | Generally lower VOCs, more environmentally friendly options available. |

Cost | Typically less expensive per square foot for materials. | Generally more expensive per square foot for materials. |

Appearance | Can be clear or pigmented, offers a high-gloss finish. | Can be clear or pigmented, offers a high-gloss finish that resists yellowing. |

Maintenance | Easy to clean and maintain. | Easy to clean and maintain. |

Best Use | Garages, industrial floors, basements, areas with less thermal expansion/contraction. | Garages, industrial floors, outdoor applications, areas with high traffic or temperature fluctuations. |

You can see polyurea offers superior flexibility and a much faster cure time compared to an epoxy resin.

Polyaspartic coatings are another excellent alternative, especially for outdoor applications or areas with significant UV exposure. Polyaspartic coatings are specifically formulated to endure UV exposure without yellowing or chalking. This ensures your outdoor surface retains its vibrant color and glossy finish for an extended period. Traditional epoxy coatings, in contrast, degrade and fade over time when exposed to the sun’s harsh rays. UV rays significantly harm most concrete coatings, causing them to fade, yellow, and lose their protective qualities. This leads to cracking, peeling, and overall degradation of the coating. Polyaspartic coatings provide superior UV resistance, making them the optimal choice for outdoor applications due to their exceptional UV stability, preventing yellowing or degradation under sunlight.

Finally, consider an acrylic coating. An acrylic coating is often a more budget-friendly option, but it offers less durability and chemical resistance than an epoxy floor paint. An acrylic coating is typically used for decorative purposes or as a sealer over concrete. When comparing acrylic vs. epoxy floor coating, you will find that an acrylic coating is easier to apply and dries faster. However, an acrylic coating will not provide the same level of protection or longevity as an epoxy floor coating. An acrylic coating is a good choice for residential patios or walkways where heavy traffic and chemical spills are not a major concern. An acrylic coating is also a common choice for refreshing the look of a floor without a major investment. An acrylic vs. epoxy floor coating decision often comes down to the required durability and budget.

Your optimal choice between crystal hardener and epoxy for your floor depends on durability and your specific epoxy needs. You must balance durability, aesthetics, maintenance, budget, and specific environmental conditions for your floor. Consider the durability an epoxy system offers. Carefully assess your floor’s unique requirements and usage patterns. Understanding these differences empowers you to select the most effective and long-lasting epoxy solution for your floor, ensuring great durability for your epoxy floor.

FAQ

Can I apply epoxy floor paint myself?

You can, but professional installation ensures the best results. Proper surface preparation is key for a durable epoxy floor paint. This helps your epoxy floor paint last longer.

How long does epoxy floor paint last?

A well-installed epoxy floor paint can last 10-20 years. This depends on traffic and maintenance. Your epoxy floor paint will serve you well.

Is epoxy floor paint slippery?

Standard epoxy floor paint can be slippery when wet. You can add anti-slip additives to your epoxy floor paint for better traction. This makes your epoxy floor paint safer.

See Also

Liquid Concrete Solutions: Hardening, Sealing, and Densifying Your Floors Effectively

Selecting Optimal Floor Hardeners: A Comprehensive Comparison Guide for 2025

Smart Floor Hardening Choices: Benefits and Drawbacks for All Surfaces

Understanding Concrete Floor Hardeners: Their Purpose and Operational Mechanics Explained

Ditch Epoxy Hassles: Transform Your Garage Floor with a Simple Densifier