Old concrete floors often appear dull, dusty, or show wear. Liquid concrete hardener offers an effective, DIY-friendly solution for revitalization. This liquid hardener transforms surfaces. It creates a harder, more durable, and dust-resistant finish. Applying liquid hardener for concrete floors improves longevity. This liquid hardener revitalizes old concrete.

Key Takeaways

Liquid concrete hardener makes old floors strong and dust-free. It works by changing the concrete to make it harder and last longer.

Applying liquid hardener is a simple DIY task. First, clean the floor well. Then, spread the hardener evenly. Finally, let it dry and cure.

Using liquid hardener protects your floor. It makes the floor resistant to water and chemicals. This helps keep the floor clean and looking good for a long time.

What is Liquid Concrete Hardener?

Defining Concrete Hardener

A concrete hardener is a treatment applied to concrete surfaces. It strengthens and protects the material. Concrete hardeners come in two main forms: liquid and powder. Powder concrete hardeners mix into the concrete during its initial batching process. They become an integral part of the concrete matrix. Liquid hardeners, however, apply to existing concrete surfaces. They penetrate the surface to react with free lime. This distinction makes liquid hardener particularly suitable for renewing old floors.

Here is a comparison of liquid and powder concrete hardeners:

Feature | Liquid Concrete Hardeners | Powder Concrete Hardeners |

|---|---|---|

Application | Applied to existing concrete surfaces | Mixed into the concrete during the batching process |

Penetration | Penetrate the concrete surface to react with free lime | Become an integral part of the concrete matrix |

Curing Time | Typically faster curing, ready for use sooner | Curing time is tied to the concrete’s overall curing |

Dusting | Primarily used to reduce dusting on existing surfaces | Can contribute to overall concrete strength and dust resistance from within |

Surface Finish | Can improve surface hardness and abrasion resistance | Enhances the entire concrete slab’s properties |

Ease of Use | Generally easier to apply, especially for DIY projects | Requires precise mixing during concrete production |

Cost | Can be more cost-effective for surface treatment | Cost is integrated into the concrete mix design |

Liquid hardener is a vital component in construction for surface enhancement. It acts as a concrete sealer and densifier. A concrete densifier is a water-based, non-toxic liquid. It penetrates the concrete surface. It reacts with free calcium to form calcium silicate. This strong compound fills tiny pores and strengthens the surface structure. This process results in a denser, harder, and dust-free floor. It can withstand pressure, abrasion, and daily wear.

How Liquid Hardener Works

Liquid hardener functions through a chemical reaction within the concrete. The active ingredients in liquid concrete hardeners include lithium silicate nanoparticles. These nanoparticles penetrate concrete and react with free lime to form insoluble tricalcium silicate. Other active chemical compounds also penetrate concrete pores. They form insoluble crystals, sealing and hardening the surface. For example, The Wall Fixer (Surface Hardener) is an aqueous product. It formulates with a highly stabilized potassium silicate solution. HC-5 Concrete hardener is a liquid hardener for concrete surfaces that is lithium-based. HC-6 Hardener/densifier is an extra lithium-based product. Maxclear HARDENER LITHIUM is also a lithium-based solution.

Liquid hardeners contain active ingredients that chemically react with calcium hydroxide present in the concrete. This reaction forms insoluble compounds, such as calcium silicate hydrate. This densifies the concrete surface and reduces its porosity. When a liquid hardener, like one based on modified sodium silicates, applies to concrete, it penetrates the material. It moves through pores, small cracks, and capillaries. Inside the concrete, chemical reactions occur. These reactions lead to crystallization that fills internal spaces. A portion of these formed crystals are hygroscopic. They absorb water and swell, subsequently forming a silica gel. This silica gel then creates a waterproofing membrane within the concrete structure. It provides durable protection against moisture and water penetration.

Liquid hardeners, particularly potassium silicate-based ones, penetrate concrete surfaces due to their low viscosity. Penetration can occur through surface application, especially on very porous supports. This results in shallower effects. Deeper penetration achieves by injecting the product into holes in the wall, either by pressure or gravity. Once inside, the hardener reacts through a process of silification. It solidifies loose parts and forms insoluble quartz crystals. This process improves the concrete’s properties by whitening its capillary network. It also creates an internal barrier against moisture. BANDě is an example of a high-quality, water-based, non-toxic, non-flammable, and environmentally friendly liquid hardener.

Key Benefits for Old Concrete Floors

The benefits of using liquid hardener for old concrete floors are significant. This treatment enhances durability and significantly improves the floor’s lifespan. MAXCLEAR HARDENER is a water-based liquid sealer. It penetrates concrete surfaces and chemically reacts. This reaction forms dense, insoluble crystals that harden the substrate. It seals pores and reduces capillary absorption. These actions collectively enhance abrasion resistance. It also provides a long-lasting dustproof finish.

The mineralizing agent consolidates the surface. It forms an internal barrier against moisture. The silidification process reacts inside the support. This process solidifies parts loosened by humidity. It forms insoluble quartz crystals that improve the support’s properties. It whitens its capillary network. This makes the floor much more resistant to wear and tear. This hardening concrete surfaces process is crucial for old, deteriorating floors.

Liquid hardener also provides excellent water resistance and chemical resistance. The silica gel formed during the reaction creates a waterproofing membrane. This protects against moisture and water penetration. The densified surface also offers improved chemical resistance, making the floor easier to clean and maintain. These properties make liquid hardener an ideal solution for renewing and protecting old concrete floors.

DIY Application of Liquid Hardener for Concrete Floors

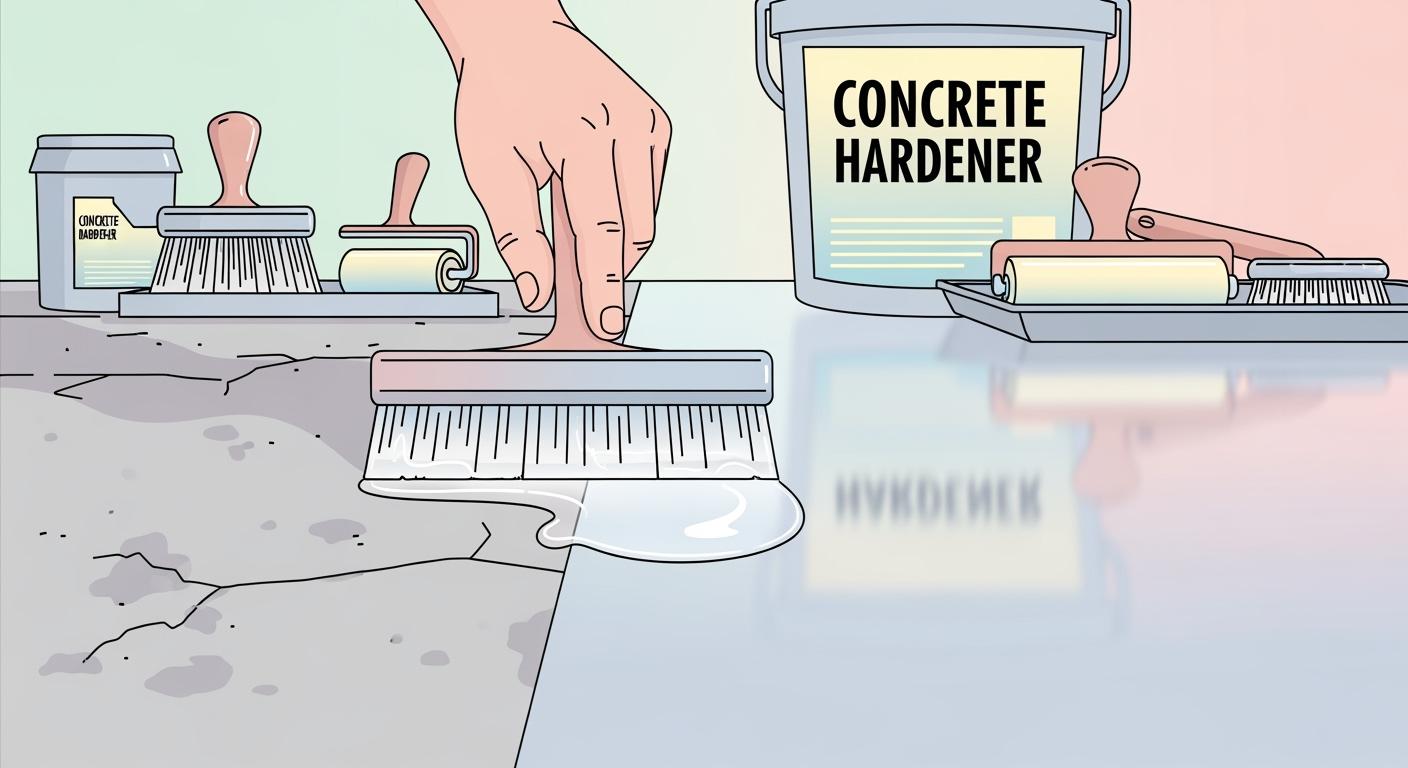

Applying liquid hardener to concrete floors transforms old, worn surfaces into durable, dust-resistant areas. This section provides a step-by-step guide for a successful DIY application, focusing on products like BANDě liquid hardener. It highlights ease of use, safety, and necessary tools.

Essential Floor Preparation

Proper preparation is crucial for the effective application of any liquid hardener. The concrete surface must be clean, dry, and free from any contaminants. Begin by removing all loose debris, dirt, and dust from the floor. A thorough sweeping and vacuuming are essential first steps. For heavily soiled floors, a degreaser or a mild detergent solution helps remove oil, grease, or other stubborn stains. Scrub the floor with a stiff brush, then rinse it thoroughly with clean water. Allow the concrete to dry completely. This drying process can take several hours or even a day, depending on humidity and ventilation. Ensure no standing water remains. Any existing sealers or coatings must be removed. This allows the liquid hardener to penetrate the concrete effectively. Grinding or chemical stripping might be necessary for this step. Patch any cracks or holes in the concrete before application. Use a suitable concrete repair compound. A smooth, uniform surface ensures optimal hardener performance.

Applying the Liquid Hardener

Once the floor is prepared, applying the liquid hardener is a straightforward process. BANDě liquid hardener, known for its user-friendly nature, simplifies this task. Before starting, gather all necessary tools and prioritize safety.

Tools for Application:

Medium/short nap roller

Drill fitted with a stirrer

Brush

Notched trowel

Spiked roller

Safety Precautions: Applying liquid hardener requires careful attention to safety. Avoid skin contact during mixing, transportation, application, and tool cleaning. Wear safety goggles or a face shield, especially when spraying or if splashing might occur. Protective gloves made of nitrile or butyl rubber are essential; change them regularly. Use respiratory protection when working with solvent-based products or when spraying. Wear appropriate protective clothing, such as trouser legs for mixing and spreading, or a full protective suit for spraying. Provide good ventilation in the work area. Consider inhalation risks, particularly with volatile hardeners or in confined spaces.

Application Steps:

Mix the Hardener: If the liquid hardener requires mixing, use a drill fitted with a stirrer. Follow the manufacturer’s instructions precisely.

Apply the First Coat: Pour the liquid hardener directly onto the concrete floor in manageable sections. Use a rubber lip, a medium/short nap roller, or a spray gun (or Airless sprayer) to spread the liquid evenly. Ensure complete saturation of the surface. The goal is to keep the surface wet for 20-30 minutes. Do not allow the liquid hardener to puddle.

Work into the Surface: For deeper penetration, use a brush or a clean push broom to work the liquid hardener into the concrete. This helps the product react with the free lime within the concrete.

Remove Excess: After the recommended dwell time (check product instructions, typically 20-30 minutes), remove any excess liquid hardener. A squeegee or wet vacuum works well for this. Do not let the hardener dry on the surface in thick layers, as this can leave white residue.

Second Coat (if needed): Some products or very porous floors may benefit from a second application. If a second coat is necessary, apply it after the first coat has dried according to the manufacturer’s recommendations.

Clean Tools: Clean all tools immediately after use with water. Disposable tools can reduce cleaning efforts.

Post-Application Care and Maintenance

After applying the liquid hardener, proper care ensures its effectiveness and longevity. The floor needs time to cure. Avoid heavy traffic for at least 24-48 hours. The full hardening process can take several days to weeks as the chemical reaction continues. During this time, protect the floor from spills and heavy impacts. Regular cleaning with a neutral pH cleaner helps maintain the floor’s appearance and integrity. Avoid harsh chemicals or abrasive cleaners, as these can degrade the hardened surface over time. A floor treated with liquid hardener becomes significantly more resistant to abrasion, dusting, and moisture. This makes it easier to clean and maintain in the long run. This simple DIY project provides a durable, renewed concrete surface.

Renewing old concrete floors with liquid hardener is easy and effective. This liquid hardener creates a hardened, wear-resistant, durable surface. The benefits of using liquid hardener are clear. This DIY project transforms floors. Choose a water-based, non-toxic, non-flammable liquid hardener like BANDě. This liquid hardener is an eco-friendly choice. This liquid hardener reduces dust, is easier to clean, and offers permanent protection. This liquid hardener is a smart investment. This concrete hardener is a smart investment.

FAQ

How long does liquid hardener take to dry?

Liquid hardener typically dries to the touch within a few hours. Full curing for liquid hardener can extend from several days to weeks.

Can liquid hardener be applied to painted concrete?

No, liquid hardener requires direct contact with concrete. Users must remove all paint or sealers before applying liquid hardener for proper penetration.

What makes liquid hardener environmentally friendly?

Many liquid hardener products, like BANDě, are water-based, non-toxic, and non-flammable. This makes liquid hardener a safer choice. This liquid hardener also reduces dust. The application of liquid hardener is eco-conscious.

💡 Tip: Always check the specific product’s instructions for exact drying and curing times for your chosen liquid hardener.

See Also

Choosing the Optimal Concrete Floor Hardener: A 2025 Selection Guide

Selecting Ideal Concrete Densifiers, Hardeners, and Sealers: A 2025 Handbook

Ultimate Guide to Concrete Sealers: Protecting Your Industrial Floors Effectively

Selecting the Premier Concrete Densifier for Your Warehouse Flooring Needs

Understanding the Mechanism: How Concrete Surface Hardeners Achieve Durability