Your warehouse floor is crucial for smooth operations and safety. Untreated concrete often battles dust, wear, and high maintenance costs. A crystal floor hardener for warehouses offers a powerful commercial flooring solution, transforming your concrete into a dense, resilient surface. Choosing the right high-quality floor coating ensures exceptional durability and longevity, saving you money long-term.

Key Takeaways

Crystal floor hardeners make your concrete floor stronger and last longer. They fill tiny holes in the concrete, which stops dust and makes cleaning easier.

Different types of crystal hardeners exist, like lithium, potassium, and sodium. Each type has special features, so pick one that fits your warehouse needs and budget.

When choosing a hardener, think about how much traffic your floor gets, what you want it to look like, and if it will be exposed to chemicals. Proper application is key for the best results.

Warehouse Floor Challenges

Untreated Concrete Issues

Your warehouse floor faces constant abuse. Without proper treatment, concrete floors quickly show their age. You will notice common problems like cracks, ranging from hairline to deeper structural issues. Surface wear and dusting are also prevalent. This happens when continuous abrasion from hard-wheeled traffic or chemical spills breaks down the surface. You might also see spalling and surface pop-outs, where concrete chips or breaks off due to impacts or construction flaws. Sometimes, steel fibers, added for strength, even become exposed if the concrete was not mixed or finished correctly.

Common Floor Deterioration

Many factors contribute to your floor’s decline. Heavy machinery use, with its constant weight and movement, creates cracks and structural weaknesses. Chemical spills can erode concrete surfaces, while environmental factors like temperature changes and moisture cause expansion and contraction. Poor installation and neglected maintenance also accelerate deterioration. You might also observe efflorescence, where salts appear on the surface as water evaporates. Joint damage is another big problem; repeated impacts from heavy wheels can break down these crucial expansion points. All these issues reduce your floor’s overall durability.

Limitations of Traditional Solutions

You might think about quick fixes, but traditional solutions often fall short. Simple patching might temporarily cover cracks, but it does not address the underlying causes of deterioration. Applying a basic sealer offers some protection, but it usually wears off quickly under heavy warehouse traffic. These methods often require frequent reapplication, leading to ongoing maintenance costs and operational disruptions. You need a more robust commercial flooring solution that penetrates the concrete and provides lasting protection against the daily grind.

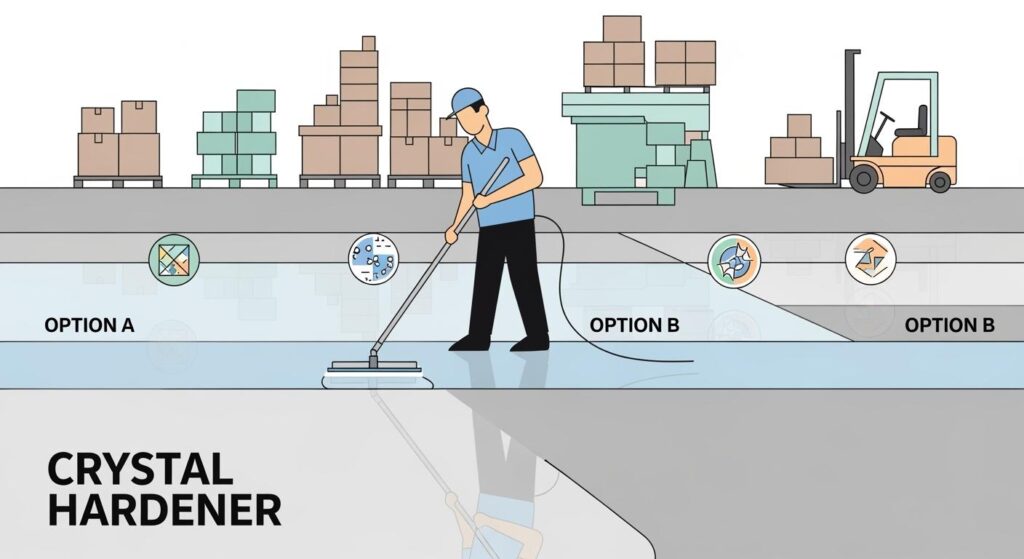

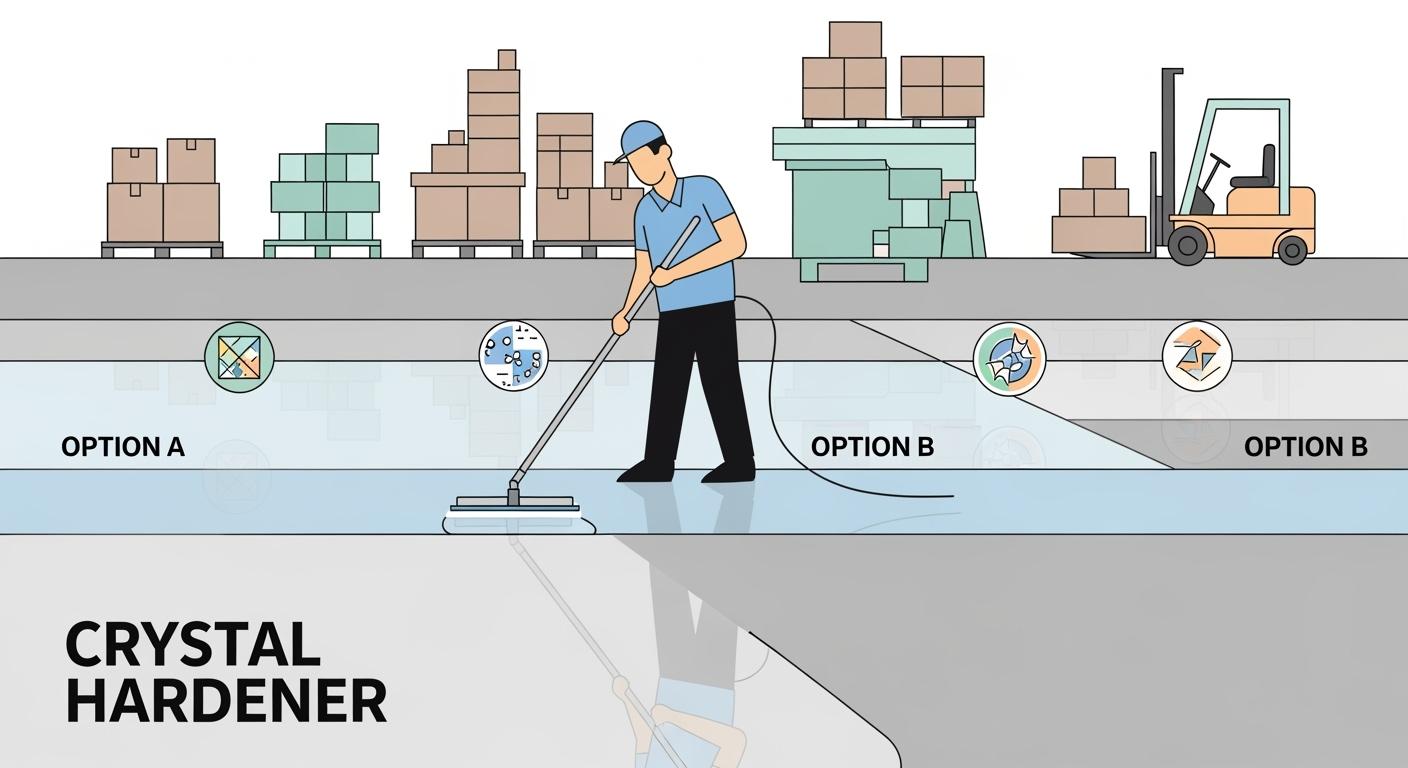

What Are Crystal Floor Hardeners

Crystal Hardener Science

Crystal floor hardeners are concrete densifiers. They work by chemically reacting with your concrete floor. When you apply these silicate-based compounds, like potassium or sodium silicate, they penetrate deep into the concrete. These silicates then react with the calcium hydroxide (or “free lime”) present in the concrete. This reaction creates calcium silicate hydrate (CSH) crystals. These new CSH crystals fill the tiny pores and capillaries within your concrete. This process makes your floor much denser and less porous. It significantly increases the concrete’s hardness, strength, and resistance to wear.

Warehouse Benefits

Choosing a crystal floor hardener for warehouses offers many advantages. You get a floor with enhanced durability that stands up to heavy traffic and impacts. These hardeners also virtually eliminate dusting, which improves air quality and reduces cleaning needs. Your floor becomes much easy to maintain because it resists stains and abrasion better. This treatment also strengthens your concrete from within, providing a long-lasting, low-maintenance surface.

Crystal Hardener vs. Other Treatments

You have other options for your floor, but crystal hardeners stand out. Unlike epoxy coatings or polyaspartic coatings, which form a layer on top of the concrete, crystal hardeners penetrate and become part of the concrete itself. This means they will not peel, chip, or delaminate. Metallic dry shake hardeners add strength but are a surface application during the pour. Crystal hardeners offer a permanent, breathable solution. They are also an excellent base for achieving a polished concrete look, providing a superior commercial flooring solution without the ongoing maintenance issues of surface coatings.

Types of Crystal Floor Hardeners

You will find different types of crystal floor hardeners, each with unique properties. Understanding these differences helps you pick the best one for your warehouse. They all work to densify your concrete, but their chemical makeup gives them distinct advantages.

Lithium Silicate Hardeners

Lithium silicate hardeners are a premium choice. They act as both a densifier and a hardener for your concrete. You get a dense, durable film that enhances adhesion and chemical resistance. This also gives you exceptional corrosion protection, especially in zinc-rich primers, thanks to their high silica-to-lithium oxide ratio. Your concrete becomes much more resistant to dusting, abrasion, and staining. You will also use less material and need fewer applications compared to other silicates because of their higher reactivity and silica concentration. They even improve bonding properties when added to other silicate formulations. Products like LIQUI-HARD ULTRA are excellent examples of these clear, water-based, zero VOC options.

Potassium Silicate Hardeners

Potassium silicate hardeners offer another strong solution. You might prefer them for applications needing high-temperature insulation or fire resistance. This is because they have a slightly higher softening point. These densifiers provide superior penetration into concrete surfaces. They give you enhanced resistance to chemicals and abrasion. You can apply them to both new and old concrete. They also improve concrete curing time and enhance its aesthetic appearance. Some potassium formulations even allow for same-day application on freshly poured concrete. They are very suitable for preparing polished concrete floors or dusting slabs. LIQUI-HARD is a well-known product in this category.

Sodium Silicate Hardeners

Sodium silicate hardeners are often the most budget-friendly option. They are widely used because of their affordability. While lithium silicates offer advanced technology and superior penetration, sodium silicates are more cost-effective. However, you must apply them correctly to avoid leaving residues. Regarding environmental impact, all water-based sealers, including sodium silicates, contribute to ‘green’ building by extending concrete life. This earns them positive ratings from LEED. Water-based products are generally considered the most environmentally friendly due to lower VOC emissions.

Selecting a Crystal Floor Hardener for Warehouses

Choosing the right crystal floor hardener for warehouses is a big decision. You need to consider many factors to ensure you get the best long-term performance and value. This section helps you navigate those choices.

Traffic and Load Assessment

First, you must understand your warehouse’s specific demands. Think about the traffic level your floor experiences daily. Do you have heavy forklifts, pallet jacks, or constant foot traffic? This assessment helps you determine the required durability. Abrasion resistance is crucial here. It measures how well a surface withstands rubbing, rolling, sliding, cutting, and impacts. Industry standards like EN BS 8204-2:2002, ASTM C779, and ASTM C944 guide these measurements. These standards also help you understand performance classes and service conditions. For example, abrasion resistance is often expressed on a Mohr scale, where 0 means very high abrasion and 10 means extremely low abrasion. Most warehouse halls need optimal deformation and compression resistance between 600 and 700 kg/cm². Knowing these numbers helps you pick a hardener that can truly stand up to your operations.

Finish and Aesthetics

The look of your floor also matters. Do you want a high-gloss finish or a more subdued, matte appearance? Crystal hardeners can prepare your floor for a beautiful polished concrete look, which many warehouses now prefer for its brightness and ease of cleaning. Consider your desired aesthetic and how the hardener will contribute to it. Some hardeners enhance the natural concrete color, while others are virtually invisible. You can achieve various levels of sheen, from a subtle satin to a mirror-like polish, depending on the product and subsequent polishing steps.

Budget and Value

You always need to think about your budget. However, focus on the long-term value, not just the initial cost. A higher initial investment in a durable concrete floor hardener often leads to substantial long-term savings. You reduce the need for frequent repairs and maintenance. High-performance hardeners in busy environments prevent costly downtime and future repairs. A well-chosen hardener extends your floor’s lifespan, making it a wise investment. For example, the reduced need for repairs, refinishing, or replacements results in significant financial benefits over time. Crystal hardeners contribute to a cleaner, more sanitary floor and offer lower maintenance requirements, making them an excellent commercial flooring solution.

Environment and Chemical Exposure

Consider what your floor might encounter. Will it be exposed to oils, acids, or other harsh chemicals? You need a hardener with good chemical resistance. Also, think about environmental impact. Many crystal hardeners are clear, water-based, and zero VOC (Volatile Organic Compound) options. Products like LIQUI-HARD and LIQUI-HARD ULTRA have obtained certifications like the California Department of Health (CDPH) VOC Emissions Certificates V1.2, 2017. This standard, also known as California Specification 01350 or CAL 01350, evaluates low chemical emissions from indoor products. It assesses predicted concentrations for 35 VOCs against maximum allowable levels. Inherently non-emitting materials like concrete are considered compliant without VOC emissions testing if they lack organic-based surface coatings, binders, or sealants. Choosing such products helps you meet environmental regulations and create a healthier indoor environment.

Compliance and Safety

Safety is paramount in any warehouse. You must ensure your chosen hardener meets relevant safety standards. OSHA has historically suggested a minimum coefficient of friction (COF) of 0.50 for workplace safety. However, this recommendation can be problematic because it does not specify the testing method, leading to inconsistent results. ASTM E303 defines the pendulum dynamic coefficient of friction (DCOF) tester, which is a widely recognized national standard for measuring pedestrian floor slip resistance. This standard has been in use for over 50 years. The most common safety standard using the pendulum for a level floor, as recommended by the Health and Safety Executive in the United Kingdom, is a minimum Pendulum Test Value (PTV) of 36. You want to ensure your chosen crystal floor hardener for warehouses does not compromise slip resistance. You can often add anti-slip additives if needed.

Application Best Practices

Surface Preparation

You cannot just pour a hardener onto any floor. Proper surface preparation is crucial for the hardener to work effectively and ensure your floor’s longevity. First, thoroughly clean the concrete. Remove all dirt, oil, grease, and other contaminants using pressure washing or industrial degreasers. If your floor has old coatings, you must remove them. Use mechanical methods like shot blasting or diamond grinding. This creates a Concrete Surface Profile (CSP) between 2 and 3, helping the hardener bond properly. After cleaning, repair any cracks or holes. Finally, ensure the surface is completely dry and dust-free before application.

Application Techniques

Once your surface is ready, apply the hardener. Always follow the manufacturer’s specific instructions for mixing and application rates. You typically apply it evenly across the surface. Let it penetrate the concrete’s porous surface, usually for 20-30 minutes. During this time, the chemical reaction begins. After penetration, remove any excess hardener with a squeegee or broom. This prevents uneven hardening and ensures a consistent finish. Accurate measurement and even application are key for optimal results.

Curing and Maintenance

After application, your floor needs to cure. This is a chemical reaction, not just drying. Maintain a stable workspace temperature, ideally between 70-75°F (21-24°C), and balanced humidity, around 40-50%. Too cold, and the hardener might not cure properly. Too hot, and it could cure too quickly. High humidity can also cause issues like cloudiness. Different products have varying full cure times, so check your product’s guidelines. Proper curing ensures maximum hardness and durability.

Avoiding Common Pitfalls

Many common mistakes can ruin your hardener application. One major pitfall is inaccurate measurement; always follow specified ratios precisely. Insufficient mixing is another problem, leading to uneven finishes or weak spots. Do not rush the mixing process. Ignoring workspace preparation, like pouring on dusty or damp surfaces, will also cause issues. Poor temperature and humidity control during application and curing can lead to incomplete curing or surface imperfections. Always read and follow the manufacturer’s instructions carefully to avoid these problems.

Investing in the right crystal floor hardener for warehouses significantly boosts your floor’s longevity and operational efficiency. You maximize durability and your return on investment through informed selection and proper application. Assess your unique needs and consult experts for the best commercial flooring solution. This ensures a future of truly durable warehouse flooring.

FAQ

How long does a crystal floor hardener last?

A crystal floor hardener becomes a permanent part of your concrete. It will last the lifetime of your floor. You get long-term durability and protection.

Can I apply a crystal hardener myself?

You can apply some hardeners yourself. However, professional application ensures the best results. Proper surface preparation and technique are crucial for optimal performance. A construction worker emoji

Are crystal hardeners safe for food storage areas?

Yes, many crystal hardeners are safe. Look for clear, water-based, zero VOC options. These products meet strict environmental and health standards for your facility.

See Also

Selecting Optimal Concrete Densifiers for Durable Warehouse Flooring Solutions

Top Floor Hardener Solutions for UK Industrial Warehouses

Ultimate 2025 Guide: Choosing the Ideal Concrete Floor Hardener

Premier Floor Hardener Solutions for Philippine Warehouse Applications