You need durable, appealing flooring. Traditional concrete often suffers from dusting and wear. Crystal clear epoxy resin provides a superior, durable solution. This epoxy floor coating enhances appearance and longevity. The global epoxy flooring market was $4.8 billion in 2024. Understanding 2025 pricing and product features is vital. You need to know the crystal floor hardener price. This helps you make a smart price decision for quality epoxy resin. Consider the overall epoxy flooring price.

Key Takeaways

Crystal clear epoxy resin makes floors strong and beautiful. It protects floors from wear and tear.

Choose your epoxy based on how clear you need it, how long it lasts, and if it resists yellowing. Also, think about how easy it is to use and how fast it dries.

Epoxy prices change due to raw material costs, how products are made, and brand reputation. Installation costs are also a big part of the total price.

Top 5 Crystal Clear Epoxy Resin Hardeners for 2025

You want the best for your floors. Here, you will find the top crystal clear epoxy resin hardeners. These products offer durability and beauty. You will also get an estimated 2025 price range for each. This helps you plan your budget.

UltraClear Epoxy Resin: Durability and Clarity

UltraClear Epoxy Resin stands out for its incredible strength. This epoxy resin is hyper-durable. It is also waterproof, making it perfect for many applications. You get a scratch-resistant finish. Plus, it is made right here in the USA. This product gives you a high-quality result. You can expect a 5-gallon kit to cost around $295.20 in 2025. This price uses a special code, HOLIDAY2025, from an original price of $369. This waterproof epoxy resin offers excellent value for your flooring project.

JANCHUN Crystal Clear Epoxy: User-Friendly Application

JANCHUN Crystal Clear Epoxy is a fantastic choice for ease of use. This epoxy resin kit, typically 16oz, is bubble-free. It also resists yellowing over time. You will appreciate its self-leveling properties. Mixing is simple with a 1:1 ratio. This makes it great for both coating and casting.

To get the best results, you should follow a few steps:

Check the Shelf Life: Make sure your resin is fresh. It lasts 12 months unopened and 6 months once opened.

Follow the Instructions: Measure and mix the resin and hardener carefully. The 1:1 ratio is key for a clear finish.

Control the Temperature: Keep your workspace between 75–85°F (24–30°C) for the first 24 hours. This helps it cure perfectly.

Many users find this epoxy resin performs well. One user noted the finish was “glass-clear, with no bubbles (as long as you take your time mixing and pour slowly).” Another user mentioned that “bubbles are not an issue unless you are making taller/thicker resin pours.” This is because the product stays liquid long enough for bubbles to escape naturally in smaller setups. The product description highlights its “self-leveling technology.” This helps you say goodbye to bubbles and bumps. You get a flawless mirror effect. The estimated price for a 16oz kit will likely remain competitive, offering great value for its quality.

TotalBoat Epoxy Resin: Versatility and Marine Grade

TotalBoat offers versatile epoxy resin solutions. Their Traditional 5:1 Marine Epoxy Resin Kits are popular. These kits range in price from $68.99 to $569.99. You might even find sales offering $9 to $120 off. They also have a 2-gallon Table Top Epoxy Resin Kit. This kit provides a crystal clear, high-gloss finish. It is UV-resistant and features an easy 1:1 mixing ratio.

While TotalBoat Table Top Epoxy Resin is “UV protected,” you should know something important. It “should not be used on surfaces that will be left outside.” Over time, it may yellow. This means it has some UV resistance, but it is not for long-term outdoor exposure. This epoxy is excellent for indoor flooring and marine projects. The price reflects its specialized applications.

EPODEX Flooring Epoxy: Fast Curing and Coverage

EPODEX Flooring Epoxy is a great option for quick projects. This epoxy is suitable for concrete, screed, and wood surfaces. You can apply it in a 1.5mm layer thickness. It boasts a fast 24-hour curing time. This means you can get back to using your space sooner. This epoxy provides a durable finish for your flooring. The price for EPODEX products will vary by volume. You can expect competitive pricing for its fast-curing benefits.

Dr. Crafty/Craft Resin: Artist’s Choice for Finish

For a professional-grade finish, consider Dr. Crafty Clear Epoxy Resin Kit. This epoxy resin ensures high-quality results for many projects. It is versatile for art resin, DIY projects, tumblers, and woodworking. Both beginners and experienced crafters find this 2-part resin kit easy to use. It delivers a flawless, high-gloss, crystal-clear finish. This resin is durable and long-lasting. It resists yellowing or cracking.

Dr. Crafty features an easy-mix formula. This helps you achieve smooth, bubble-free results. It is also non-toxic and low-odor for safe indoor use. This epoxy is UV resistant for long-lasting clarity. You get a strong, durable, and transparent finish. The easy 1:1 resin to hardener mix ratio is convenient. You have 45 minutes of work time at room temperature. The kit often includes tools like measuring cups, mixing sticks, and spreaders. It also comes with a comprehensive instruction manual. This makes it one of the best high-quality epoxy kits available. The crystal floor hardener price for these professional-grade options reflects their superior performance and included accessories.

Key Factors for Selecting Your Ideal Floor Hardener

Choosing the right crystal clear epoxy floor hardener goes beyond just looking at the crystal floor hardener price. You need to consider several key factors. These help you make an informed decision for your flooring project.

Optimal Clarity and Aesthetic Appeal

You want your floors to look amazing. A clear epoxy resin can transform ordinary floors. It creates stunning, high-gloss surfaces. This breathes new life into aged floors. You can also customize your epoxy flooring with textures and colors. This helps match your home décor or design style.

Long-Term Durability and Wear Resistance

Your floor needs to last. A durable epoxy floor coating resists wear. It stands up to heavy traffic. The ASTM D4060 standard measures abrasion resistance. This ensures your epoxy can handle forklifts and foot traffic without degrading. High-quality epoxy resin and hardener are crucial. They ensure your floor lasts. A well-installed epoxy floor can last 5 to 20 years or longer, even under heavy traffic.

UV Stability and Non-Yellowing Properties

You want your clear epoxy to stay clear. Epoxy can yellow over time. UV light exposure is a main cause. Chemical reactions and the quality of the resin also play a role. Look for epoxy resin with UV inhibitors like hindered phenols or benzotriazoles. These help prevent yellowing.

Application Difficulty and Curing Time

Consider how easy the epoxy is to apply. Some epoxy resin kits are user-friendly. They offer simple 1:1 mixing ratios. Proper surface preparation is also key for good adhesion. You must clean, dry, and sand surfaces before applying epoxy. Fast curing times mean you can use your floor sooner.

Project Specifics and Traffic Requirements

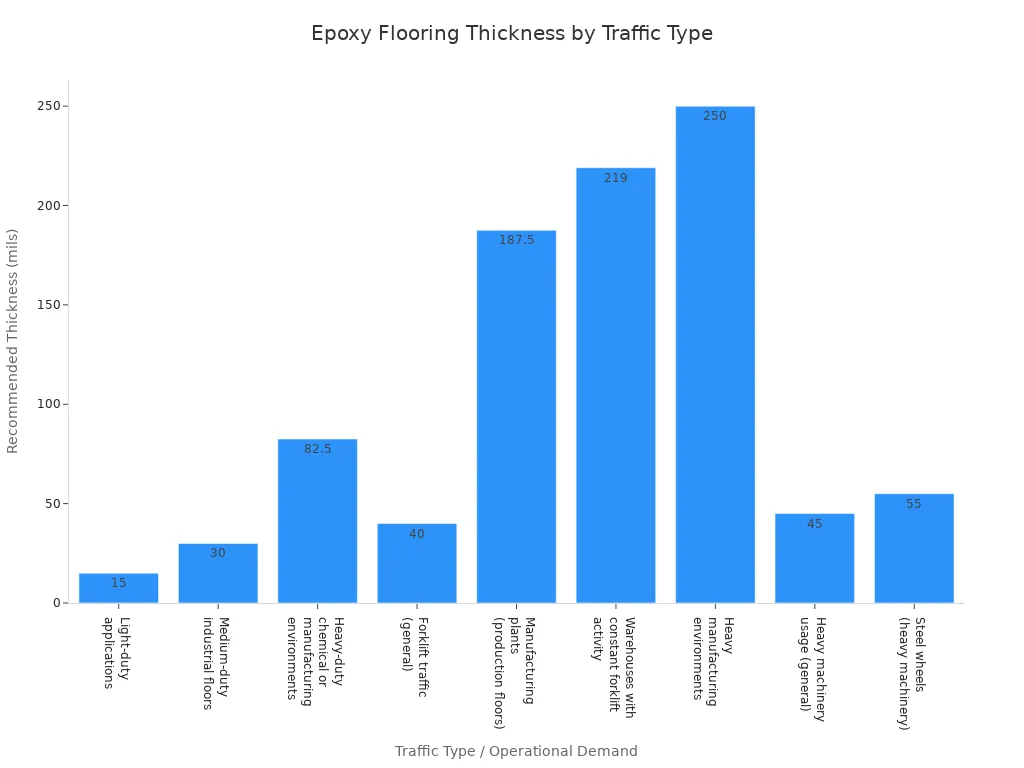

Think about your project’s unique needs. Different environments demand different epoxy thicknesses.

Traffic Type/Operational Demand | Recommended Thickness (mils) |

|---|---|

Light-duty applications (e.g., foot traffic) | 10-20 |

Medium-duty industrial floors | 20-40 |

Heavy-duty chemical or manufacturing environments | 40-125 |

Forklift traffic (general) | 40+ |

Manufacturing plants (production floors) | 125-250 |

Warehouses with constant forklift activity | 188-250 |

Heavy manufacturing environments | >250 |

For example, a commercial kitchen needs USDA approval. It requires high adhesion, impact resistance, and chemical resistance. The price of your epoxy will reflect these specific demands.

Decoding 2025 Epoxy Flooring Price Trends

You need to understand more than just the product cost. Many factors influence the overall epoxy flooring price. This helps you make sense of the estimated product prices you saw earlier.

Raw Material Costs and Market Fluctuations

You might wonder why the price of your chosen epoxy floor hardener changes. A big reason is the cost of raw materials. Epoxy resins come from petroleum-based materials. So, when crude oil prices go up or down, the cost of these raw materials changes too. This directly affects the crystal floor hardener price. These price shifts can even hurt profit margins for smaller businesses. Global crude oil price volatility and big world events, like the Russia-Ukraine conflict, have really messed up the supply of epoxy resins. These resins are super important for concrete floor coatings. The jump in crude oil prices directly increased the cost of petrochemicals like propylene. Propylene is a key ingredient for epichlorohydrin, which is a main part of epoxy resins. This means chemical manufacturers worldwide face higher input costs. The conflict also made it harder for Europe to get natural gas. Natural gas is essential for chemical processing. This reduced output and made it tough to export industrial feedstocks because shipping routes were blocked. Companies like Covestro and Hexion have raised prices and cut production. They faced feedstock problems and energy costs that were too high. This ultimately increases prices and makes project timelines longer for concrete coatings. The volatility of raw material prices is a big challenge in the epoxy resin market. Since epoxy resin production relies on petrochemicals, changes in crude oil prices directly impact manufacturing costs. Manufacturers need good plans to handle these price changes. This helps them keep a stable supply chain. This directly influences the overall epoxy flooring price you see.

Manufacturing and Supply Chain Impact on Price

Beyond raw materials, manufacturing and supply chain issues also influence the cost. You might face delays or higher expenses because of several factors. These include plant closures, extreme weather conditions, and logistics problems. Increases in crude oil costs also play a role here. The industry also struggles with too much capacity and slowing demand in some areas. Complex global trade dynamics and an imbalance between supply and demand in the petrochemical industry add to the challenges. You might also see shipping delays, container shortages, and rising logistics expenses. Raw material inflation, geopolitical risks, port closures, and currency fluctuations all contribute to higher costs for epoxy products. These issues make it harder for manufacturers to get their epoxy resin to you efficiently. This impacts the final cost you pay for your flooring.

Brand Reputation and Performance Value

You also pay for a brand’s reputation and the performance you expect. Well-known brands often charge more. They have a proven track record for reliability. Think about UltraClear Epoxy Resin. Its hyper-durable, waterproof, and scratch-resistant qualities justify its price point. You are investing in a product that delivers consistent results. TotalBoat Epoxy Resin also shows this. Its marine-grade versatility and UV resistance for indoor use reflect its higher value. A higher price often means better ingredients and more rigorous testing. This ensures your epoxy floor lasts longer and looks better. You get the quality you pay for.

Regional Demand and Availability Factors

Where you live also affects the cost. Regional demand and how easily you can get products play a big role. North America, for example, leads the global epoxy flooring market. However, specific demand differences within North America, like between the U.S., Canada, and Mexico, are not detailed here. Still, you can expect that areas with higher demand or fewer suppliers might see higher costs. Local availability impacts shipping expenses and overall convenience. If an epoxy product is hard to find locally, you might pay more for it. This is true even for a high-quality epoxy.

Installation Costs and Professional Services

Finally, you must consider installation costs. The product cost is only one part of your total epoxy floor expense. Professional installation of an epoxy floor coating generally costs between $4 and $9 per square foot. For solid-color epoxy, materials are $2 to $4 per square foot. You then add an extra $3 to $5 per square foot for professional installation. The average professional installation cost for epoxy typically ranges between $2 and $12 per square foot. This cost depends on factors like surface preparation, the complexity of the design, and the specific type of epoxy system you choose. You should always get multiple quotes to ensure you get a fair cost for your project.

You invest in high-quality crystal clear epoxy resin for durable, beautiful flooring. This epoxy resin offers long-term savings for your flooring. Consider product features and 2025 pricing for your strategic epoxy resin investment. Assess your project needs using our guide. These advanced epoxy resin flooring solutions create cleaner, safer, and more appealing environments.

FAQ

How long does clear epoxy flooring last?

You can expect your clear epoxy floor to last 5 to 20 years or even longer. This depends on traffic and maintenance. High-quality products and proper installation extend its life.

Can I apply epoxy myself?

Yes, you can! Many kits offer user-friendly 1:1 mixing ratios. You need to prepare the surface well. Follow the instructions carefully for the best results.

Does clear epoxy yellow over time?

Some clear epoxies can yellow. You should choose products with UV inhibitors. These additives help prevent yellowing. This keeps your floor looking clear and beautiful.

See Also

Top Floor Hardeners: A 2025 Comparison Guide for Optimal Selection

Picking the Ideal Concrete Floor Hardener: Your 2025 Selection Guide

Extend Concrete Life: 2025 Application Guide for Floor Hardeners

Liquid Concrete Solutions: Hardener, Sealer, and Densifier Explained

Buying Guide: Concrete Densifiers, Hardeners, and Sealers Comprehensive Overview