You often hear “crystal floor hardener” and “concrete densifier” used interchangeably for your concrete flooring. These terms describe the same chemical treatments, designed to enhance the flooring surface. Their goal is to increase hardness, density, and durability through a chemical reaction within the flooring surface. These products strengthen the cement paste on the surface, not the Tobermorite structure. Deep application beyond this crucial wear surface offers little practical benefit for your flooring. We will clarify their mechanisms and application.

Key Takeaways

Crystal floor hardeners and concrete densifiers are the same product. They both make concrete stronger and last longer.

These products work by creating a chemical reaction in the concrete. This reaction fills small holes and makes the surface harder.

Using these products makes your floor more durable. It also reduces dust and makes the floor look better.

Understanding Terminology: Same Product?

You might often hear “crystal floor hardener” and “concrete densifier” used as if they are different products. However, you should know that these terms largely refer to the same class of chemical treatments. Both are penetrating liquid solutions. They chemically react with your concrete to improve its properties.

Defining Crystal Floor Hardener

When you hear “crystal floor hardener,” you are usually talking about a specific type of treatment for your concrete flooring. These products often contain finely graded non-metallic quartz aggregates. They also include plasticizers and cement binders. These components work together to create a very hard surface. The “crystal” part of the name often refers to the crystalline structure that forms within the concrete. This structure can give your floor a polished, reflective finish, enhancing your overall flooring.

Defining Concrete Densifier

A “concrete densifier” is another liquid treatment you apply to your concrete surface. These products use active silicate ingredients. You will find sodium silicates, potassium silicates, and lithium silicates in many formulations. Some also contain colloidal silica. These silicates react with the calcium hydroxide in your concrete. This reaction fills the pores in your concrete, making the surface much denser and harder. It significantly improves the integrity of your flooring.

Why Terms are Interchangeable

You might wonder why people use these terms interchangeably. The reason is simple: they perform the same core function for your concrete flooring. Both treatments penetrate your concrete surface. They both create a chemical reaction. This reaction makes your concrete stronger and more durable. Essentially, a crystal floor hardener is a type of concrete densifier. A concrete densifier often creates a “crystal-like” hardened surface. So, you can think of them as two names for the same effective solution for your flooring.

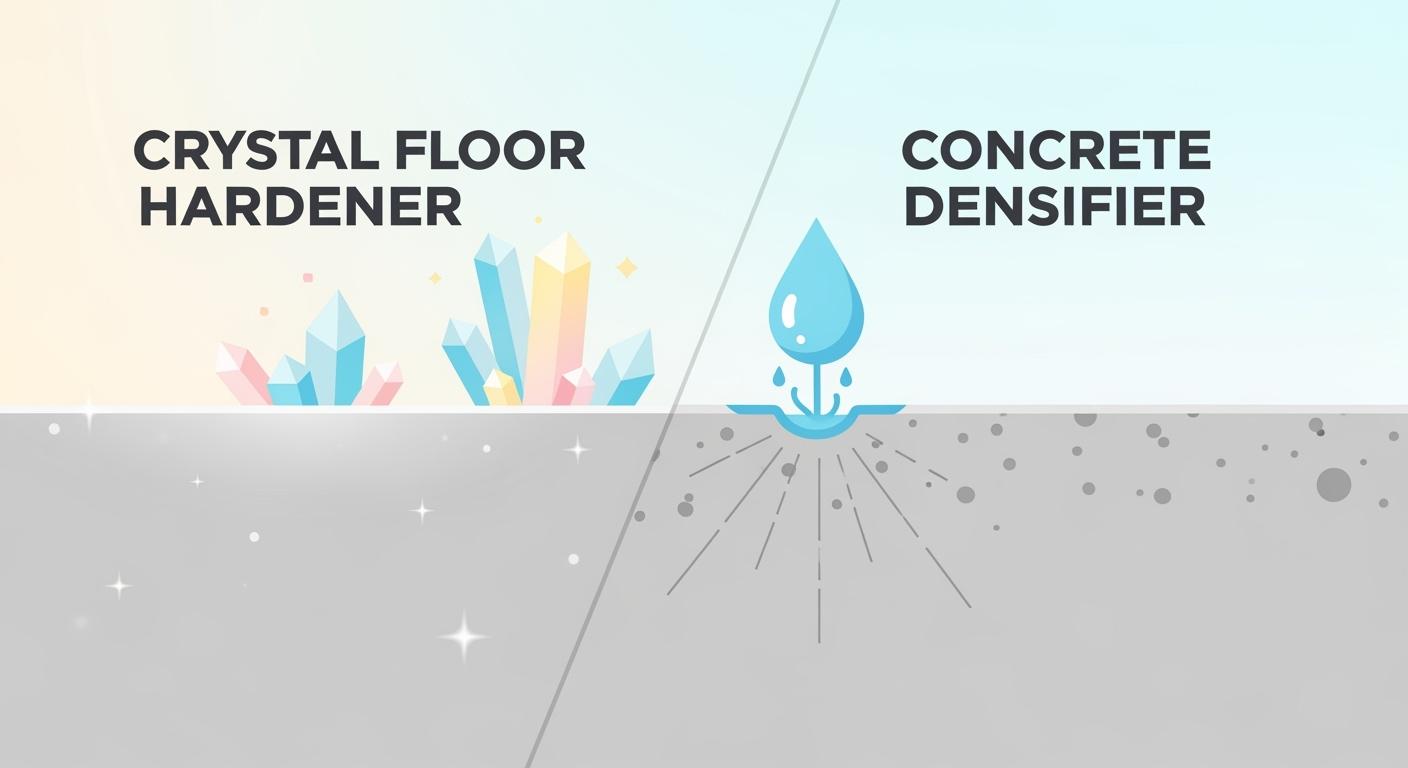

Science Behind Strength: How They Work

You might wonder how these treatments make your concrete so much stronger. It all comes down to a clever chemical process happening right within your concrete flooring. These products do not just sit on the surface; they become part of it.

Chemical Reaction with Concrete

When you apply a concrete densifier, you introduce active silicates to your concrete. These silicates can be sodium, potassium, or lithium-based. They seek out and react with the calcium hydroxide in your concrete. Think of it as a chemical handshake. This reaction is crucial for strengthening your concrete surface. For example, products like LIQUI-HARD are proprietary, water-based, clear silicate liquids. Manufacturers formulate them specifically for hardening and dustproofing your concrete flooring.

C-S-H Gel Formation

This chemical reaction creates something amazing: Calcium Silicate Hydrate, or C-S-H gel. This gel is the primary binding phase in concrete. It makes up about 70% of fully hydrated Portland cement. The C-S-H gels polymerize and harden into tiny globular masses. They form successive layers that are vital for your concrete’s strength and durability. This gel fills the microscopic pores within your concrete, increasing its density and surface hardness. A denser, purer C-S-H gel directly improves your cured concrete’s ability to resist heavy loads. The nanostructure of this C-S-H significantly influences the strength and overall performance of your flooring.

Deep Penetration for Durability

These treatments are not just skin deep. They penetrate your concrete surface, often reaching depths of 1/8 inch to 1/4 inch per application. This deep penetration is key to long-lasting durability for your flooring. It means the hardening effect goes beyond the immediate surface, creating a more robust and resilient concrete. However, some silicate densifiers have larger particle sizes. This can sometimes limit how deeply they penetrate into your concrete flooring.

Key Benefits for Your Floor

You gain many advantages when you treat your concrete flooring with a densifier. These treatments significantly improve your floor’s overall quality and longevity.

Enhanced Hardness and Abrasion Resistance

You will notice a remarkable increase in your floor’s hardness. Densifiers create a much denser surface, which directly translates to superior abrasion resistance. This means your flooring can withstand heavy foot traffic and equipment without showing wear and tear quickly. You get better performance and increased durability from your concrete.

Eliminating Dusting and Improving Air Quality

Untreated concrete often creates dust, which can be a nuisance and affect air quality. Densifiers penetrate the surface, binding loose particles and preventing this dusting. This results in a cleaner environment and better air quality for your space. Your flooring stays cleaner, and you breathe easier.

Lasting Shine and Aesthetics

Densifiers enhance the long-term aesthetic appeal of your concrete flooring. They fill pores with hardening agents, creating a smooth, even surface. This smooth surface reflects light beautifully, giving you a high-gloss, mirror-like finish. This lasting brilliance is not just superficial; it penetrates deep into the concrete, elevating the overall sophistication of your space. Some formulations even enhance the concrete’s natural color, bringing out subtle variations.

Increased Stain and Chemical Resistance

You will find your densified concrete flooring much more resistant to spills. These floors, especially when treated with quality densifiers and sealers, resist water and stains effectively. They also improve chemical resistance and reduce water permeability. This means spills are less likely to penetrate and damage your surface.

Extended Lifespan, Low Maintenance

A high-quality densifier can extend your concrete floor’s lifespan significantly, even to “a lifetime.” The densifier permanently grows new crystals within the concrete, filling pores and voids. This creates a dense, hard, and wear-resistant surface. You will also appreciate the reduced maintenance needs. This long-term durability means less frequent repairs and lower maintenance and care costs over time, offering excellent performance.

Applications and Project Suitability

You can use concrete densifiers in many different places. They work well for various types of flooring projects.

Industrial and Commercial Use Cases

Densifiers are perfect for demanding industrial and commercial settings. They make your flooring incredibly tough.

Healthcare: These floors offer cost-effectiveness and low maintenance. They meet strict hygiene and safety standards.

Manufacturing: You get exceptional durability. The floors resist heavy loads, machinery, and chemical spills.

Food and Beverage: The non-porous surface prevents bacteria and mold. This helps with cleaning and sanitation. This application makes your flooring last longer and perform better.

Retail and Institutional Environments

Retail spaces also benefit greatly from densified concrete. You need durable and attractive flooring here. Densifiers make floors more durable and easier to maintain. They increase surface hardness. This is great for high-traffic areas. You will see reduced dusting and less maintenance. They also improve stain resistance. This makes cleanup faster. Your floors will look glossier and brighter. This enhances the appearance of your retail space.

Residential and Garage Floors

Don’t forget your home! Densifiers are excellent for residential garage floors. You get improved stain resistance. This helps with oil and chemical spills. Your floor will have a longer lifespan and need less maintenance. It will also look better. The surface becomes harder. This resists wear and scratches. You also get dust-proofing. This improves cleanliness and air quality. This application is a smart choice for your home flooring.

New vs. Existing Concrete Surfaces

You can apply densifiers to both new and existing concrete. For new concrete, you apply it after the concrete cures. The installation is straightforward. For existing concrete, proper preparation is key. You need to clean the surface thoroughly. This ensures the densifier penetrates well. Good preparation leads to the best results for your flooring.

Choosing the Best Hardener for 2025: A Buying Guide

You want the best for your concrete flooring. Choosing the right hardener or densifier can feel overwhelming. This guide helps you make an informed decision for your project in 2025.

Factors in Product Selection

When you select a concrete densifier, you need to think about several key factors. First, consider your project’s specific needs. What kind of traffic will your floor see? For high-traffic commercial facilities, you primarily use concrete densifiers to increase the abrasion resistance of the floor. They react with calcium hydroxide in the concrete. This produces more calcium silicate hydrate. This enhances the concrete’s durability at the surface where abrasion occurs. This makes them ideal when wear from traffic is your main concern.

You should also assess your concrete’s surface characteristics. Look at its porosity, hardness, and any existing sealers or coatings. Define your desired outcome. Do you want increased hardness, reduced dusting, enhanced abrasion resistance, or improved durability? Ensure the densifier is compatible with your concrete’s age, composition, and prior treatments. Think about the application technique. Choose a densifier that works with your application methods and tools. Finally, consider environmental factors. Select an eco-friendly densifier that complies with relevant regulations.

Different densifier types offer unique benefits for high-traffic areas:

Densifier Type | Key Benefits for High-Traffic Areas |

|---|---|

Lithium Silicates | High penetration, harder surface, ideal for high-traffic areas, reduces porosity, improves stain and water damage resistance. |

Sodium Silicates | Affordability, ease of application, good hardness, effective in reducing dusting. |

Potassium Silicates | Densifies and strengthens at a molecular level, known for chemical resistance (useful if chemicals are present in high-traffic areas). |

Understanding Product Specifications

You need to look closely at product specifications. These details tell you a lot about a densifier’s quality and how it will perform. For example, specifications like solids content, pH, and viscosity directly impact how well a densifier works. A low solids formulation, like DryShield densifier, often means deeper penetration into the concrete. Its pH-neutral nature is also a key feature.

Here are some typical specifications you might see:

Specification | Value |

|---|---|

Solids (weight) | |

Viscosity | Less than 25 cps (typical) |

You want a product with proven penetration depth and a significant hardness increase. These specifications ensure you get a high-quality product that delivers on its promises for your flooring.

Advanced Formulations and BANDě Densifier

You will find advanced concrete densifier formulations on the market today. These include products with colloidal silica or specialized silicate blends. These advanced options offer superior performance compared to traditional silicate densifiers.

Feature | Colloidal Silica Densifiers | Traditional Silicate Densifiers |

|---|---|---|

Mechanism | Penetrates concrete pores, reacts with calcium hydroxide to form calcium silicate hydrate (CSH) gel, filling pores and increasing density. | Reacts with calcium hydroxide to form CSH gel, but the larger silicate molecules may not penetrate as deeply or uniformly. |

Particle Size | Nanoparticles (typically 5-100 nm) | Larger molecules |

Penetration | Deeper and more uniform penetration into concrete pores due to smaller particle size. | Less deep and uniform penetration. |

Density & Hardness | Significantly increases surface density and hardness, improving abrasion resistance. | Increases density and hardness, but potentially less effectively than colloidal silica. |

Permeability | Reduces permeability, enhancing resistance to water, chemicals, and staining. | Reduces permeability, but may be less effective at blocking all pore sizes. |

Durability | Improves long-term durability and extends the lifespan of concrete. | Improves durability, but the extent may vary. |

Application | Can be applied to new or existing concrete. | Typically applied to new or existing concrete. |

Appearance | Can enhance the natural appearance of concrete, often providing a subtle sheen. | May alter the appearance of concrete, sometimes leaving a residue or discoloration. |

Environmental Impact | Generally considered environmentally friendly, often water-based with low VOCs. | May contain higher VOCs or other less desirable chemicals depending on the formulation. |

Cost-Effectiveness | Offers long-term cost savings due to enhanced durability and reduced maintenance. | Initial cost may be lower, but long-term benefits might be less pronounced. |

Key Benefits | Superior penetration, enhanced density, improved abrasion resistance, reduced permeability, increased durability, better aesthetic integration. | Basic densification, some permeability reduction. |

Limitations | May require multiple applications for optimal results, higher initial cost. | Can leave a white residue if not applied correctly, less effective penetration. |

Specific Use Cases | High-traffic areas, industrial floors, decorative concrete, areas requiring superior chemical resistance. | General concrete densification, less demanding applications. |

These advanced formulations provide superior penetration and enhanced density. They also offer improved abrasion resistance and reduced permeability. This leads to increased durability and better aesthetic integration for your concrete surface. Products like BANDě Concrete Densifier exemplify these high-performance characteristics. They offer the kind of quality you expect from a top-tier crystal floor hardener.

Environmental and Safety Standards

You must consider environmental and safety standards when choosing a densifier. Look for products with certifications that demonstrate their commitment to a healthy environment and indoor safety.

Many products contribute to LEED credits. For example, concrete densifiers like Ashford Formula can contribute points by extending the life of existing building stock. This is because the product lasts the lifetime of the building. It allows for reuse of existing materials in renovation projects. You can also gain points if your project is within 500 miles of the product’s manufacturing location.

Environmental Product Declarations (EPDs) are crucial. These are third-party verified reports. They detail a product’s full environmental profile. They help validate sustainability claims and document compliance with green building standards. EPDs for concrete densifiers contribute to LEED credits. They count as a product-specific, third-party verified Type III EPD.

Look for products with LEED v4 VOC Indoor Emission Test Certificates. These specifically mention compliance with CDPH Standard Method 1.2-2021. MAS Certified Green® is another important certification. It ensures products meet rigorous testing requirements for chemical emissions. This is vital for the safety of your indoor environment and the overall installation process.

You now understand that crystal floor hardener and concrete densifier are the same effective concrete treatment technology for your flooring. These solutions offer significantly improved durability, reduced maintenance, enhanced aesthetics for your surface, and a longer-lasting flooring surface. Focus on product quality and proven performance for your specific flooring needs, not just the name. This ensures optimal performance and easy maintenance and care for your concrete surface. This also reduces overall maintenance and care for the entire surface. Invest in high-quality solutions like BANDě Concrete Densifier for the best results on your concrete flooring surface.

FAQ

Can I apply a concrete densifier over existing epoxy flooring?

No, you cannot apply a densifier over existing epoxy flooring. Densifiers need to penetrate bare concrete. You must remove any epoxy or other coatings first. This ensures proper chemical reaction.

How do concrete densifiers improve indoor safety?

Densifiers reduce concrete dusting, which improves air quality. Many products also have low VOC emissions. This contributes to a healthier environment and better indoor safety for you.

Do concrete densifiers offer long-term cost savings?

Yes, they do. Densified floors last longer and need less maintenance. This means you save money on repairs and upkeep over many years. You get excellent value.

See Also

Unveiling the True Distinction: Concrete Densifiers Versus Hardeners Explained

Liquid Concrete Solutions: Hardeners, Sealers, and Densifiers for Floors

Understanding Concrete Floor Hardeners: Their Purpose and Operational Mechanics

Demystifying Concrete Densifiers: Exploring Their Functionality and Application

Selecting Optimal Floor Hardeners: A Comprehensive Comparison Guide for 2025