A concrete floor hardener enhances hardness, durability, and resistance. This hardener improves overall floor durability. Robust floor hardening materials are critical for Indonesia’s demanding industrial environments, ensuring strong and durable floors. This guide offers construction professionals a comprehensive understanding of floor hardener types, benefits, and application for this essential concrete floor hardener.

Key Takeaways

Floor hardeners make concrete floors stronger and last longer. They protect floors from damage and heavy use.

There are different types of floor hardeners, like powders, liquids, and coatings. Each type works in a special way to improve the floor.

Choosing the right hardener and putting it on correctly is important. This makes sure the floor stays strong and works well for a long time.

Types and Mechanisms of Floor Hardeners

Defining Floor Hardener and Its Purpose

A floor hardener densifies the surface of floors. It creates a tough, wear-resistant finish. This material enhances durability, vibrance, and color depth. Unlike regular coatings, a floor hardener integrates into the surface. This ensures lasting strength and fade resistance. It is ideal for both decorative and industrial flooring.

A concrete floor hardener is a material applied to the surface of a concrete slab. Its primary purpose is to enhance the concrete’s hardness and durability. It works by penetrating or bonding with the concrete. This process creates a denser, harder surface. This improves resistance to wear, impact, and chemicals. A hardened surface extends the floor’s lifespan. It makes the floor suitable for high-traffic areas or spaces with heavy machinery or equipment. Facilities use floor hardening materials for factory floors, warehouses, parking floors, and garages. They are suitable for areas requiring light, medium, or heavy traffic. This application increases the abrasion resistance capability of the concrete floor surface. It also minimizes dust on the concrete floor surface.

Dry Shake Floor Hardeners: Powder Application

Dry shake hardeners are factory-blended powders. They contain cement, special hardwearing aggregates, and various additives. For example, Triflor Diamond Hard contains special hardwearing aggregates selected for abrasion and wear resistance, as well as shape and size. It also includes high-performance workability admixtures. Sikafloor 3 Quartz Top Colored Mineral Dry Shake Floor Hardener contains ‘Colored Mineral’ and ‘Quartz Top’. Workers apply these powders to fresh, wet concrete surfaces. They then trowel the powder into the concrete. This process creates a monolithic bond with the fresh concrete.

Dry shake hardeners enhance concrete wear resistance by forming a dense, non-porous, and extremely hard-wearing surface. This blend of special hard-wearing aggregates, chosen for their abrasion and wear resistance, combines with Portland cement and specific additives. This formulation allows the hardener to bond monolithically with fresh concrete. It creates a robust surface. This surface overcomes issues typically associated with thin screeds, such as curling, shrinkage, and cracking. This type of hardener also offers the option to add color to the concrete surface.

Liquid Chemical Floor Hardeners: Densifiers and Reactivity

Liquid chemical floor hardeners, also known as concrete densifiers, penetrate the concrete surface. These chemical floor hardeners are typically silicate-based solutions. Examples include sodium, potassium, or lithium silicates. They react chemically with the free lime present in concrete. This chemical reaction forms calcium silicate hydrate (C-S-H). C-S-H is a hard and dense material. It fills the pores within the concrete surface. This process significantly improves the concrete’s strength and durability.

Liquid concrete hardeners, specifically those based on metallic silicate with high silica content, chemically react with the free lime and cement mortar within the concrete. This reaction leads to the formation of a hard, synthetic quartz-like material. This material contributes to an abrasion-resistant and dust-free finish on the concrete surface. This type of liquid floor hardener permanently seals the concrete from stains. BANDě Concrete Densifier is a leading silicate-based densifier that exemplifies this mechanism. It helps to increase surface density and overall performance.

Epoxy and Polyurethane Floor Hardening Materials

Epoxy and polyurethane floor hardening materials differ from penetrating hardeners. They form a protective film on the concrete surface. An epoxy coating or a polyurethane coating creates a durable, non-porous layer. This layer protects the concrete from abrasion, impact, and chemical spills. These materials are thermosetting polymers. They cure to form a hard, resilient surface.

These film-forming hardeners do not penetrate the concrete to react chemically. Instead, they bond strongly to the surface. This creates a barrier. This barrier offers excellent resistance to various environmental factors. They provide a distinct aesthetic finish, often glossy or colored. This makes them suitable for areas requiring both high performance and visual appeal.

Benefits, Applications, and Selection in Indonesia

Key Benefits of Hardened Concrete Floors

Hardened concrete floors offer numerous advantages, making them a preferred choice for various industrial and commercial settings. These floors exhibit significantly increased abrasion resistance. This means they withstand daily wear and tear from foot traffic, machinery, and equipment movement much better than untreated concrete. They also boast enhanced impact strength. This protects the floor from damage caused by dropped tools or heavy objects. A key benefit is reduced dusting. Untreated concrete often releases fine dust particles, which can be problematic in sensitive environments. A concrete floor hardener creates a denser surface, minimizing this issue.

Furthermore, hardened floors provide improved chemical resistance. This is crucial for industrial settings. For example, epoxy grout offers exceptional chemical resistance. It withstands acids, alkalis, solvents, and heavy-duty cleaning agents. This makes it ideal for food processing plants, pharmaceutical facilities, laboratories, and automotive areas. Similarly, PU Concrete resists chemical attacks from acids, alkalis, oils, and organic solvents. This prevents degradation that other flooring materials often experience in chemical environments. This enhanced resistance leads to lower maintenance costs. The floor does not crack, crumble, or deteriorate easily, minimizing downtime and repair work. Hardened surfaces are also more hygienic and easier to clean. Their smooth, non-absorbent nature prevents dirt and contaminants from penetrating. This maintains a hygienic environment and prevents bacterial growth. The overall durability of these floors ensures a strong and durable surface for many years. This extended durability makes a concrete floor hardener a wise investment.

Common Applications for Floor Hardening Materials in Indonesia

Floor hardening materials find widespread use across various sectors in Indonesia due to their superior performance. Industrial facilities commonly utilize them. These include all concrete industrial floors, both old and new. Warehouses, factories, and logistics centers benefit greatly from the added durability. Specific examples include loading/unloading bays, aircraft hangers, breweries, production areas, manufacturing factories, workshops, and industrial laboratories. Specialized environments like wafer and power plants, precision machinery rooms, and clean rooms also rely on these materials. Pharmaceutical factories, hazardous chemical factories, and food processing factories use them for their hygiene and chemical resistance properties. Kitchens, restaurants, staircase and corridors, storage areas, AHU rooms, and chemical storage rooms also benefit from a robust hardener.

Retail spaces and parking garages also frequently employ floor hardening materials. Parking areas, car parks, and garages require surfaces that can withstand constant vehicle traffic and oil spills. Showrooms and exhibition halls use them for their aesthetic appeal and durability. Hotels and apartment floors, as well as mall and shopping center floors, benefit from the enhanced wear resistance. Even terrace and homeyard areas can utilize a hardener for increased longevity. These applications highlight the versatility and necessity of floor hardening materials in Indonesia’s diverse construction landscape.

Choosing the Right Concrete Floor Hardener

Selecting the appropriate concrete floor hardener requires careful consideration of several factors. The type of traffic the floor will endure is paramount. Different types of traffic, such as those involving small, hard wheels (e.g., pallet transporters, hand trucks) or softer tires (e.g., counterbalance lift trucks), create varying wear mechanisms and surface pressures. This necessitates specific hardener choices to achieve high abrasion resistance. Dry shake surface hardeners, chemical hardeners, and high-performance coatings offer cost-effective solutions for achieving high abrasion resistance. Each enhances the performance of the concrete floor and meets specific application requirements.

Environmental conditions in Indonesia also play a significant role. Hot weather (above +25 °C) can cause some products to gel too quickly. Cold weather (below +10 °C) may thicken the product, making application difficult. High humidity (80% to 100%) or wind-free conditions can increase gelification time. Exposure to moisture after application can lead to efflorescence. Therefore, understanding these conditions helps in selecting a hardener that performs optimally. Other factors include the desired aesthetic, budget constraints, and specific performance requirements like slip resistance or color. A thorough assessment ensures the chosen floor hardener provides optimal durability and functionality.

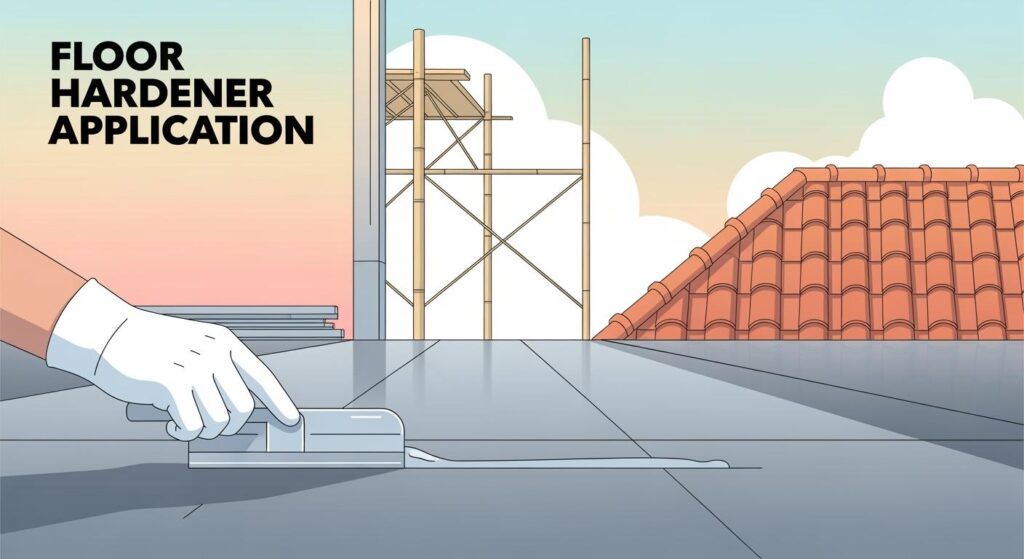

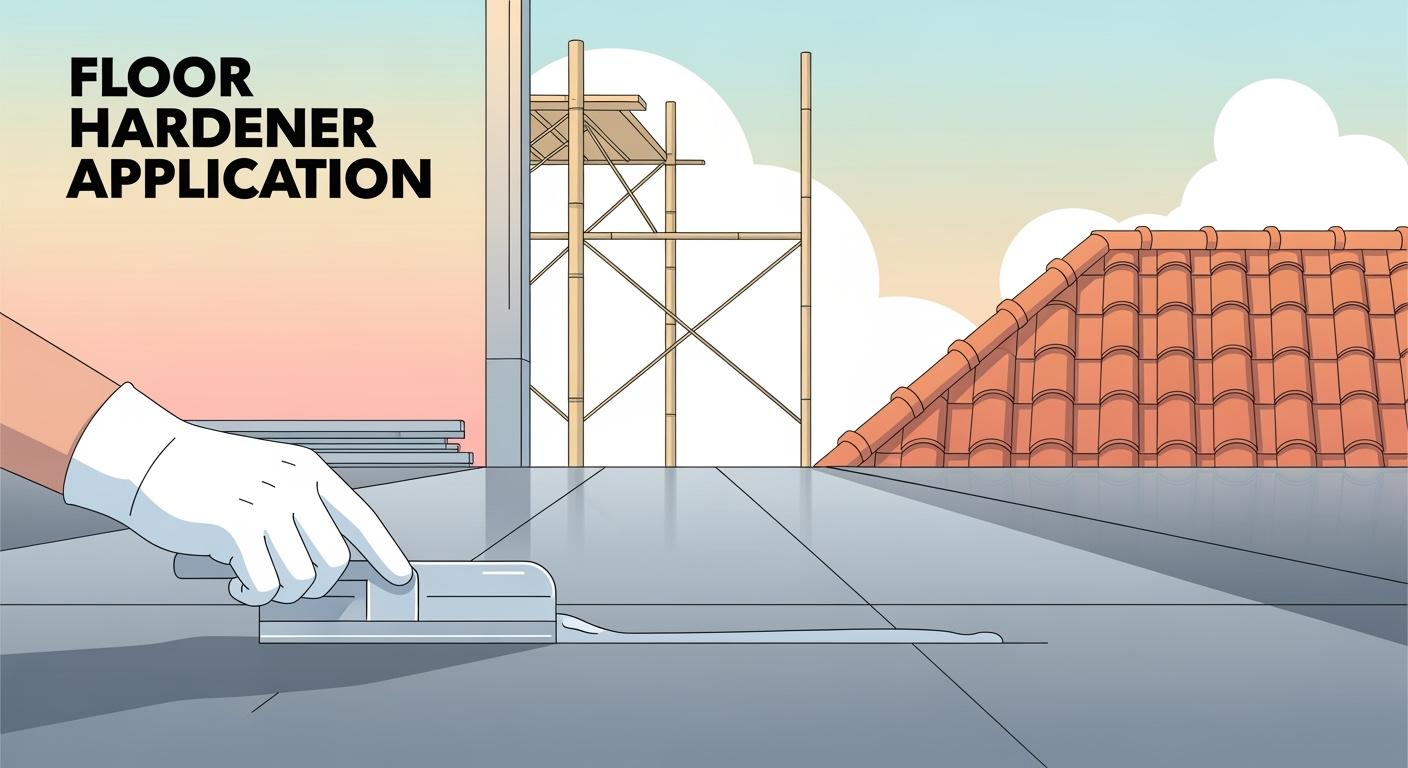

Best Practices for Floor Hardener Application

Proper application is crucial for maximizing the effectiveness and durability of any floor hardener. Surface preparation is the first and most critical step. The concrete floor surface must be thoroughly cleaned of dirt, dust, and other foreign matter. Surfaces should be free from grease, oil, chemical contamination, dust, laitance, and loose concrete. Workers must remove fragile parts from the surface. Use appropriate equipment like a shot blaster, scarifier, or grinder to achieve a sound substrate. Degrease surfaces with oil traces using a chemical degreaser before any surface preparation. Level uneven concrete to produce flat surfaces. New concrete floors must be at least 28 days old. The moisture content of concrete or cementitious floors must be less than 5%.

Expansion, control, and isolation joints should be carried through floors and filled with a suitable sealant. Cracks should be filled; if hairline cracks are less than 2mm wide, slightly open them using a chisel hammer. After opening cracks, clean all loose debris and clean the cracks with a wet brush and water, ensuring the floor is dry afterward. Ensure the floor surface is free from dust, oil, grease, laitance, or any other material that could cause debonding of crack fillers. Following these meticulous preparation steps ensures the hardener bonds effectively and delivers its intended performance. Mixing instructions provided by the manufacturer must be followed precisely. Application techniques vary depending on the hardener type, involving spraying, troweling, or broadcasting. Finally, proper curing is essential for the hardener to achieve its full strength and durability.

Proper selection and application of a concrete floor hardener bring significant value to Indonesian construction. This ensures long-lasting, high-performance concrete surfaces. Understanding different floor hardening materials and their mechanisms is key to informed decisions. These decisions contribute to project success and enhanced durability. Professionals should prioritize quality solutions. This enhances infrastructure longevity and functionality, ensuring greater durability.

FAQ

What is the main purpose of a floor hardener?

A floor hardener increases concrete hardness and durability. It improves resistance to wear, impact, and chemicals. This extends the floor’s lifespan, making it suitable for demanding environments.

What are the main types of floor hardeners?

The main types include dry shake powders, liquid chemical densifiers, and film-forming epoxy or polyurethane coatings. Each type works differently to enhance and protect concrete surfaces.

Why are hardened floors important in Indonesia?

Hardened floors withstand heavy traffic and harsh conditions common in Indonesian industrial and commercial settings. They ensure long-lasting, high-performance surfaces, contributing to project success and durability.

See Also

Understanding Concrete Floor Hardeners: Their Purpose and Operational Mechanics

Top Floor Hardener Solutions for Warehouses Across the Philippines

Selecting the Optimal Floor Hardener: A Comprehensive Comparison Guide for 2025

Premier Floor Hardener Solutions for Industrial Warehouses in the UK

The Essential 2025 Guide to Choosing Your Ideal Concrete Floor Hardener