Concrete often suffers damage. Selecting the correct concrete repair material is crucial for lasting durability and performance.

Choosing the wrong option leads to premature repair failure, resulting in wasted investment, increased costs, and potential safety risks.

How does one navigate the many modern concrete repair products for a specific application, from simple concrete crack repair to complex structural concrete repair?

Key Takeaways

Choose the right repair material for concrete damage. Cement mortars are good for general fixes. Epoxy systems are better for strong, chemical-resistant repairs.

Always check the type of damage and where the concrete is located. This helps you pick the best material for a lasting repair.

Think about how much the repair costs and how long it will last. A more expensive material might save money over time.

Understanding Concrete Repair Materials

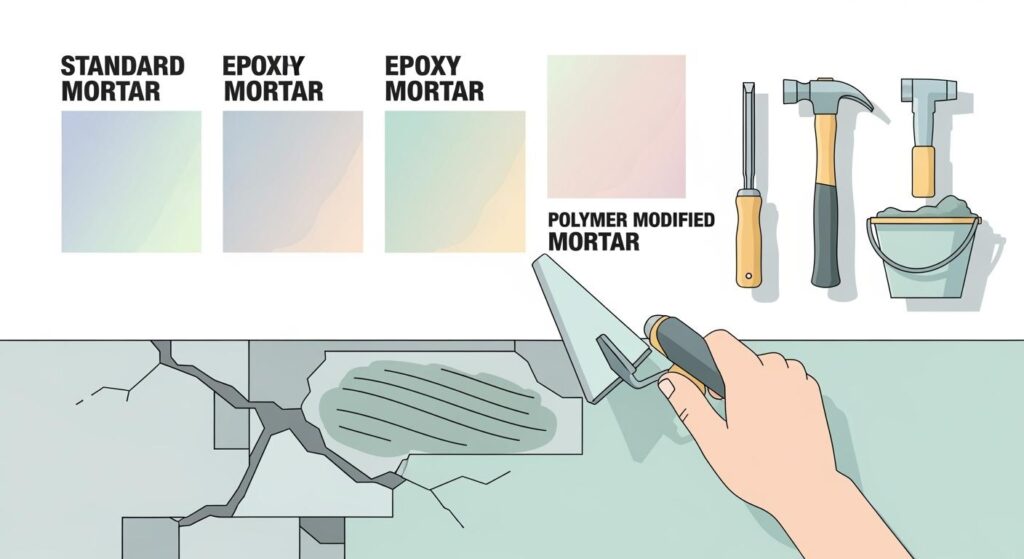

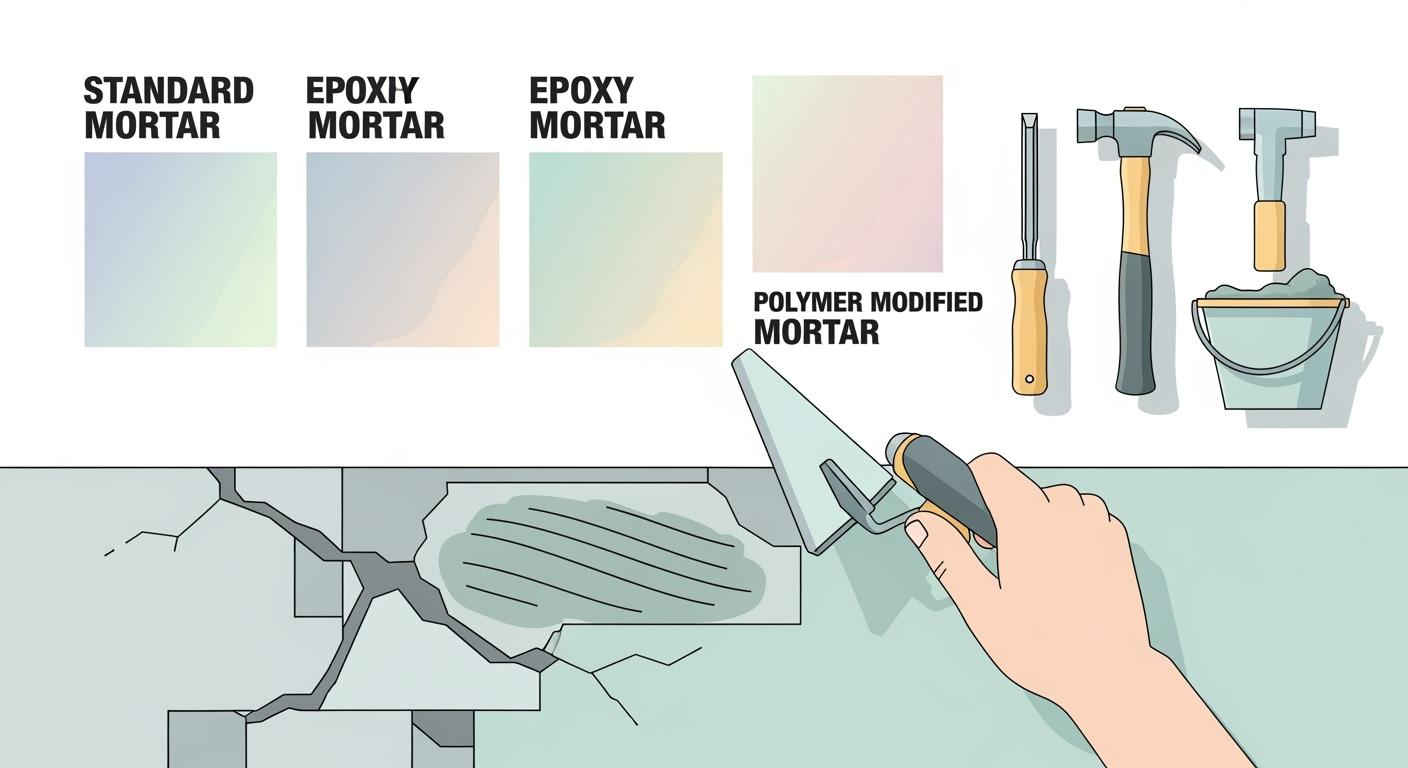

When you face damaged concrete, choosing the right material is crucial. You have two main categories: mortars and epoxies. Each offers distinct advantages for different types of concrete repair. Let’s explore what makes them unique.

Defining Repair Mortars

Repair mortars are mineral-based mixtures. They typically consist of cement, sand, and water, sometimes with added admixtures. Think of them as a more refined version of the original concrete. They are generally cost effective and often easy to apply, making them a popular choice for many common repairs. A good repair mortar for concrete blends well with existing structures. These cement based repair mortars are versatile. They are excellent for patching spalled areas or filling larger voids. This type of mortar provides a solid, durable fix for many situations, especially where flexibility is not a primary concern.

Defining Repair Epoxies

Epoxy systems are quite different. They are resin-based materials. These systems offer exceptional properties. They provide very high bond strength and excellent chemical resistance. Epoxy based repair mortars are also impermeable. This means they stop water penetration effectively. They also boast superior abrasion resistance. This makes them ideal for high-traffic areas or environments with chemical exposure. An epoxy repair is often chosen for critical structural repairs. This type of epoxy ensures a long-lasting repair for damaged concrete. The strength of epoxy is undeniable.

Cement Based Repair Mortars

When considering concrete repair, cement based repair mortars are a traditional and highly effective choice. They come in several forms, each suited to different repair needs.

Standard Cementitious Mortars

These are the most basic type of cement based repair mortars. They consist of cement, sand, and water, often with some admixtures. They are excellent for general concrete repair tasks. A good repair mortar for concrete helps restore the original profile and function of damaged concrete. These mortars are cost-effective and relatively easy to work with.

Polymer-Modified Mortars

Polymer-modified mortars take standard cement based repair mortars a step further. They include special polymer additives, like Re-dispersible Polymer Powders (RDPs). These additives significantly improve the mortar’s performance. For instance, RDPs enhance bonding, adhesion, and flexural strength. They also boost workability and impact resistance. Products like duoMatrix-C are polymer additives that improve the physical properties of cementitious materials. BluCem HB50 is another example; it is a polymer-modified, cementitious powder blend offering dual shrinkage control and better resistance to chlorides, sulphates, and marine environments.

Rapid-Setting Mortars

Sometimes, a repair needs to be completed very quickly. This is where rapid-setting mortars come in. They contain chemical accelerators to speed up the setting process. Sika Rapid AF, for example, is a non-chloride set accelerator used in concrete and mortar to achieve faster setting times and improved early strength. This allows for quicker finishing and a faster return to service for the repaired area.

Type of Concrete | |

|---|---|

Rapid Set Concrete | Sets in 20-40 minutes, reaches full strength in 1 day |

Standard Pourable Concrete | Takes 7-28 days to reach full strength |

Pros and Cons of Cement Mortars

Cement based repair mortars offer many advantages. They effectively repair concrete defects, restoring structural integrity and durability. They also improve the appearance of the structure. These mortars provide superior adhesion compared to traditional mixes and offer effective shrinkage control, which leads to improved durability. However, they generally take longer to cure than epoxy systems.

Cement Mortar Applications

Cement based repair mortars are incredibly versatile. They are widely used for structural repairs on roads, bridges, and buildings. They also fix cosmetic defects. For example, they are perfect for restoring spalling and damaged concrete in various structures. They can strengthen structures by adding mortar to enhance bearing capacity. Another important application involves preserving or restoring passivity by increasing cover and replacing contaminated concrete to protect reinforcement.

Epoxy Repair Systems: A Side-by-Side Comparison

Now, let us turn our attention to epoxy repair systems. These materials offer a different set of advantages compared to cement-based mortars. This section provides a side by side comparison of various epoxy types, helping you understand their unique strengths.

General Purpose Epoxy Mortars

General purpose epoxy mortars are versatile workhorses in the world of concrete repair. They combine epoxy resins with aggregates, creating a strong, durable material. These mortars are excellent for patching, resurfacing, and filling voids in concrete. They offer good adhesion and strength for many common repair tasks. For general purpose epoxy mortars, a common mix ratio is 3:1. This ratio is suitable for versatile 100% solids epoxy resins. These resins find use in residential, commercial, and industrial applications, offering high cured strength.

High-Strength Epoxy Grouts

When a project demands extreme strength and precision, high-strength epoxy grouts become the material of choice. These grouts are specially formulated to withstand heavy loads, vibrations, and harsh conditions. They are often used for anchoring machinery, structural column bases, and other critical applications where maximum load transfer is essential. Their impressive mechanical properties make them stand out:

Property | Value | Test Method |

|---|---|---|

Compressive strength (6 hrs) | ~ 20 MPa | N/A |

Compressive strength (1 day) | ~ 90 MPa | N/A |

Compressive strength (7 days) | ~ 100 MPa | N/A |

Modulus of elasticity in compression | ~ 18,000 MPa | ASTM D 695-96 |

Tensile strength in flexure | > 35 MPa | ASTM C 580 |

Modulus of elasticity in flexure | ~ 16,000 MPa | EN 53452 |

Tensile strength | > 14 MPa | ASTM D 638 |

Tensile adhesion strength (on steel) | ~ 9 MPa | ISO 4624, EN 1542 and EN 12188 |

Tensile adhesion strength (concrete failure) | > 3.5 MPa | ISO 4624, EN 1542 and EN 12188 |

Shear adhesion strength (concrete failure) | > 47 MPa | ASTM C 882 |

Linear Shrinkage | -0.027% | ASTM C 531 |

Linear Shrinkage | -0.03% | EN 52450 |

Coefficient of thermal expansion (-30°C to +30°C) | 2.1 x 10-5 mm/mm/°C | ASTM C 531 |

Coefficient of thermal expansion (+24°C to +100°C) | 4.4 x 10-5 mm/mm/°C | ASTM C 531 |

Water absorption (7 days) | 0.059% | ASTM C 413 |

Flexible Epoxy Resins

Not all concrete repair requires rigid materials. Sometimes, a degree of flexibility is necessary to accommodate movement or thermal expansion. Flexible epoxy resins offer this unique characteristic. They can bridge cracks and absorb minor movements without cracking themselves. This makes them ideal for specific applications where some give is beneficial. For example, Surfset FLEX Epoxy Resin, when cured, exhibits excellent tensile properties. It provides the desired drive and flex characteristics essential for performance surf products, showing its ability to handle dynamic stresses.

Pros and Cons of Epoxy Systems

Epoxy systems bring many benefits to concrete repair. They offer superior structural strength, often surpassing the original concrete. This reinforces compromised areas effectively. Epoxy forms a tight, waterproof bond, preventing further deterioration and offering excellent chemical resistance. This leads to multi-decade performance and reduced maintenance costs.

They can be injected into both dry and damp cracks.

Epoxy hardens effectively under dynamic loads.

Low viscosity and surface tension allow for excellent penetration into the finest crack widths, making epoxy injections very effective.

They possess high compressive and tensile strengths.

However, epoxy systems also have their drawbacks. They can be more expensive initially than cementitious mortars. Their installation process is often lengthy, requiring extensive preparation and strict drying times. Epoxy floors can become hazardous when wet, needing anti-slip treatments. During application, some epoxy coatings release toxic fumes, requiring good ventilation and protective gear. They are also susceptible to UV damage, which can cause fading or discolouration over time.

Consider this side by side comparison of factors:

Factor | Epoxy-Based Repair Mortar |

|---|---|

Bond Strength | Excellent adhesion to concrete and steel, forming a strong, permanent bond. |

Setting Time | Fast-curing, ready for load in a few hours. |

Compressive & Flexural Strength | High strength, resistant to heavy loads, vibrations, and impact. |

Chemical Resistance | Excellent; resists acids, oils, solvents, and industrial chemicals. |

Cost | Higher initial cost but lower long-term maintenance. |

Advantages | High bond strength, fast curing, superior mechanical and chemical resistance, and long-term durability. |

Epoxy Repair Applications

Epoxy repair materials are incredibly versatile. Their fast-curing and sticky nature makes them suitable for horizontal, vertical, and even overhead applications. You can use them for a wide range of tasks, from minor crack repairs to major structural bonding.

Some common applications include:

Megapoxy HX: This product is used for repairing cracked concrete through gravity penetration or low-pressure injection.

Megapoxy P1: A gap-filling adhesive suitable for a wide range of applications.

Megapoxy PF: A rapid-setting epoxy adhesive for immediate, on-the-spot repairs.

Megapoxy PM: A non-sag epoxy filling and adhesive paste for various applications.

Epirez 133: A general-purpose epoxy mortar binder that, when combined with aggregate, creates concretes and mortars with excellent adhesion and high strength.

Epirez 633: A solventless, non-sag epoxy paste for vertical or overhead applications.

Epirez Multi II: A multi-purpose epoxy for concrete repair and bonding of various construction materials.

For example, Sikadur®-32 is an excellent epoxy-based product. It bonds new concrete to old concrete, steel, and other substrates, showcasing the strong adhesive power of epoxy.

Specialised Repair Options

Sometimes, standard repair materials just do not quite fit the bill. For unique challenges, specialised options offer targeted solutions. These materials address very specific problems in concrete.

Polyurethane Injection Resins

When dealing with cracks that leak water, polyurethane injection resins are often the go-to choice. These resins react with water to form a flexible, watertight seal. They are excellent for water ingress treatment in basements or tunnels. The injection process uses high pressure. For example, dual component drill pumps can pump in excess of 100 bar. Some systems, like the Wagner SF23, operate at pressures up to 250 bar for polyurethane crack injections. Single component drill pumps also inject polyurethane at pressures over 100 bar.

Acrylic Polymer Mortars

Acrylic polymer mortar offers distinct advantages. They improve bond strength between the repair material and the existing concrete. These mortars also enhance workability, strength, and durability. They provide excellent adhesion, flexibility, and weather resistance. This makes them ideal for flexible and long-lasting patches. They also cure faster than traditional materials.

Lime Mortars for Historic Structures

For very old buildings, especially historic structures, lime mortars are essential. Modern cement-based materials can be too rigid. They can damage softer, older masonry. Lime mortars are breathable and flexible. They work in harmony with historic building materials. This ensures the long-term preservation of the structure.

Specialised Material Applications

The choice of specialised materials depends on the specific repair need. For structural cracks, epoxy injections are often best. Polyurethane crack injections are perfect for dynamic cracks or damp basement walls. Polymer-modified repair mortars suit non-structural cracks and patch repairs. For larger voids or honeycombing in concrete repair, cementitious grouts are effective. Fast-setting materials are ideal for high-traffic areas like car parks. They allow areas to reopen quickly.

Choosing the Best Concrete Crack Repair Materials

Selecting the right materials for concrete crack repair can feel like a puzzle. Many factors influence this decision, from the type of damage to the environment. Making an informed choice ensures a durable and effective repair. Let us explore the key considerations.

Assessing Damage and Crack Characteristics

Before you even think about materials, you must understand the crack itself. A thorough assessment is the first crucial step. It helps you pick the best concrete crack repair materials.

While most types of cracks may not affect structural stability or durability, the identification of a crack’s status is critically important. Determining the type of crack and its origin helps in deciding the necessary repairs. Even small and fine cracks (less than 0.3 mm in width) are generally considered acceptable for minor settlement, depending on the concrete structure’s purpose, environment, design-life, and durability design. Nevertheless, a qualified professional should be consulted to classify the severity, investigate the cause, and determine the most effective repair method if required.

Several methods help assess these characteristics. Impact Echo Testing, for instance, is a non-invasive technique. It uses resonant responses to stress waves to evaluate a structure’s integrity and thickness. This method also detects flaws like cracks, voids, and delaminations. Another useful tool is Ultrasonic Pulse Velocity (UPV) testing. This non-destructive method measures sound wave speed through the material. It assesses quality, uniformity, and identifies defects. For vertical cracks, UPV Crack Depth Measurement determines their depth. It adheres to standards like BS 1881 Part 203, measuring surface velocities near the crack and using a trigonometric formula to estimate depth.

Other common assessment techniques include:

Crack Measurement: This involves optical measurement or monitoring of crack width on the concrete surface over time.

Crack Monitoring: Devices and sensors installed around a crack record changes in its width over time, especially for ‘live’ cracks that are still moving.

Visual Inspection: This involves observations recorded on paper or digital applications, including taking and categorising photographs.

Understanding these details guides you towards the most suitable concrete crack repair solution.

Structural Concrete Repair Considerations

When cracks affect the structural integrity of a building or element, you face a different challenge. This is where structural concrete repair becomes paramount. For instance, if a crack compromises a load-bearing wall or beam, the repair material must restore the original strength and load-carrying capacity. You cannot just patch it up. A structural concrete crack repair often requires materials that match or exceed the strength of the existing concrete. Engineers typically specify these materials. They ensure the repair integrates seamlessly and safely with the structure. Always consult a professional for any suspected structural concrete repair.

Environmental Exposure and Chemical Resistance

The environment where the concrete structure sits plays a massive role in material selection. What conditions will the repair face?

Consider these environmental factors:

Temperature Fluctuations: Concrete can crack due to thermal expansion and contraction, affecting structural integrity.

Moisture and Humidity: High humidity can lead to deterioration, while water intrusion weakens foundations. Waterproofing and moisture barriers are crucial.

Saltwater Exposure: The corrosive nature of saltwater accelerates deterioration. Corrosion-resistant materials and protective coatings are necessary.

Wind Forces: High-speed winds can exploit weaknesses, particularly affecting roofs and windows.

Earth Movements: Earthquakes, landslides, and soil subsidence cause foundational shifts and cracks, requiring seismic design or retrofitting.

Solar Radiation: UV light deteriorates materials. UV-resistant coatings and materials are recommended.

Air Pollution: Airborne pollutants, like acid rain, chemically weather materials and accelerate corrosion. Regular cleaning and protective sealants are used.

Biological Factors: Tree roots can undermine foundations, and wildlife can damage roofing.

Beyond natural elements, chemical exposure is a significant concern, especially in industrial settings. Concrete repair solutions must include chemical resistance to be considered complete, alongside waterproofing. This helps resist chloride intrusion and prevents moisture build-up.

In industrial environments, concrete repair materials must withstand attacks from acids, alkalis, sulphates, and chlorides. These substances are common in manufacturing plants, chemical processing facilities, and wastewater treatment plants. They penetrate concrete, alter its chemical composition, and lead to degradation, cracking, spalling, and corrosion of embedded steel. Therefore, protective coatings, such as epoxy coatings, are crucial. They provide a barrier against harsh chemicals, offering strong adhesion and resistance in environments with significant wear and chemical exposure.

Here are some examples of chemical-resistant options:

Epoxy Coatings: These offer excellent chemical resistance and durability. They suit industrial warehouses, manufacturing facilities (e.g., milk, yoghurt), workshops, and kitchens where exposure to corrosive chemicals is common.

Chemical Resistant Coatings for Storage Tanks: These are essential for maintaining the integrity of tanks storing chemicals (water/sewer treatment, chemical bunds, fuel storage). They prevent corrosion and degradation of concrete or steel structures.

Setting Time and Curing Conditions

The speed at which a repair material sets and cures significantly impacts project timelines and the final performance. Temperature is crucial for the curing process, with ideal ranges typically between 10°C and 25°C. Extreme temperatures can significantly affect hydration rates and the development of concrete strength. Preventing moisture loss is equally important, as wind, sunlight, and low humidity can cause rapid evaporation. This leads to surface cracking and reduced strength. These factors directly influence how quickly concrete sets and cures effectively.

High ambient temperatures can cause the water in the concrete mix to evaporate too quickly. This leads to incomplete hydration and potentially faster but weaker setting. Conversely, cold temperatures slow down the chemical reactions involved in curing, which extends the setting time. Low humidity also contributes to faster moisture loss, while high humidity can slow down the drying process, making the curing take longer. Ideal conditions for pouring concrete are mild temperatures, specifically between 15°C and 25°C, and low humidity to ensure proper curing and strength development.

Warm climate concreting, as defined by ACI, involves conditions such as high ambient temperature, high concrete temperature, low relative humidity, and excessive wind speed. These factors accelerate the rate of moisture loss and cement hydration, which can impair the quality of freshly combined or hardened concrete. When combined with low relative humidity and strong winds, these conditions require special care during setting and finishing due to their impact on the setting time. A nomogram illustrates the combined effects of air temperature, humidity, concrete temperature, and wind velocity on the rate of water evaporation from freshly placed concrete. For instance, with an air temperature of 25°C, relative humidity at 40%, concrete temperature at 25°C, and a wind velocity of 20 km/hr, the evaporation rate would be 1.1 kg/m² hr. This tool helps determine evaporation rates. Rates exceeding 0.5 kg/m² hr indicate potential for plastic cracking, and rates over 1.0 kg/m² hr necessitate precautionary measures to prevent plastic shrinkage. Higher evaporation rates due to temperature and humidity directly influence the speed at which concrete sets.

Proper curing is just as vital as the material choice for any modern concrete repair.

Renderoc HB70, for example, should be cured immediately after finishing.

You can cure it using products like Nitobond AR or Concure A99.

The curing compound should be sprayed onto the surface of the finished Renderoc in a continuous coat.

Overcoating with clear sealants can extend the life of the repair by offering additional protection.

General concrete curing involves maintaining moisture levels for an extended period to ensure strength, durability, and watertightness. Improper curing reduces strength gain and negatively affects quality. Techniques include:

Spraying

Impermeable membranes

Ponding

Wrapping in wet sand or hessian

Misting concrete 5-10 times daily with water is an effective way to maintain moisture, especially in hot weather.

Covering concrete with water-retaining materials like plastic sheeting or hessian fabrics can maintain moisture, but these materials must not dry out completely.

These steps are crucial for successful concrete crack repair.

Cost and Longevity Factors

Finally, consider the cost versus the expected lifespan of the repair. While a cheaper material might save money upfront, it could lead to more frequent repairs down the line. High-quality concrete, when properly mixed and cured, can achieve a service life of 50 to 100 years. However, this longevity can be significantly reduced by exposure to harsh weather conditions, chemical attacks, and mechanical stress if these issues are not addressed. Regular maintenance and timely repairs are crucial for mitigating these risks and extending the overall durability of concrete structures.

Investing in the best concrete crack repair materials for your specific situation often proves more cost-effective in the long run. Modern concrete repair solutions offer enhanced durability and performance, reducing the need for future interventions. Always weigh the initial cost against the long-term benefits and expected service life. This approach helps you make the most economical and effective decision for your concrete repair.

Informed material selection is paramount for durable concrete repair. We explored cement based repair mortars, epoxy, and specialised options. Each offers unique strengths for concrete repair, including concrete crack repair. No single modern concrete repair solution fits all. Consult product data sheets and professional advice for structural concrete repair. This ensures long-term durability and performance.

FAQ

What is the main difference between repair mortar and epoxy?

Repair mortars are mineral-based, cost-effective, and easy to apply. Epoxies are resin-based, offering superior strength, chemical resistance, and excellent bonding for critical repairs.

When should one choose rapid-setting mortar?

Rapid-setting mortars are ideal when a repair needs quick completion. They allow faster finishing and return to service for the repaired area.

Are epoxy systems always the best choice for concrete repair?

Not always. Epoxies offer high strength and chemical resistance but cost more. Cement mortars are often sufficient and more economical for many general repairs.

See Also

Selecting Superior Cementitious Repair Mortar: A 2025 Expert’s Handbook

Achieving Enduring Repairs: Your Definitive Handbook for Cement Crack Sealers

BANDě’s 2025 Handbook: Selecting Optimal Concrete Masonry Primer for Projects

Top Five Concrete Masonry Primers: Essential Choices for Your 2025 Projects

Choosing the Ideal Concrete Floor Hardener: A 2025 Comprehensive Handbook