You want durable, low-maintenance concrete floors, right? Water-based crystal floor hardeners are a popular option, promising enhanced durability and great dust control for your concrete. This guide gives you a balanced look at these hardeners. We explore their advantages and disadvantages. Knowing both the good and bad helps you choose the right hardeners for your concrete.

Key Takeaways

Water-based crystal floor hardeners make concrete floors much stronger. They stop dust and last longer. This helps your floor handle heavy use better.

These hardeners do not change how your floor looks. You must clean and fix the concrete surface very well before applying them. This helps the hardeners work correctly.

Hardeners are not for fixing broken concrete. They make good concrete even better. They also need time to dry before you can use the floor a lot.

Understanding Water-Based Crystal Floor Hardeners

How They Work

A water-based crystal floor hardener isn’t just a surface treatment; it chemically changes your concrete. These hardeners, often called concrete densifiers, penetrate deep into the concrete. They react with free lime (calcium hydroxide), a natural byproduct of concrete curing. This chemical reaction creates calcium-silicate-hydrate (C-S-H) gel. This gel forms dense, hard crystals. It fills the pores within the concrete. This process binds the concrete and the densifier together. You get a stronger, more durable, and less porous surface. This also stops dusting. YUNYAN’s concrete hardeners, including lithium silicate densifiers and reactive polymers, chemically bond with the free lime in the concrete matrix. This interaction forms the C-S-H crystalline structure. This structure increases surface hardness and strength. Lithium silicate hardeners achieve deep penetration and crystal formation. Sodium silicate hardeners provide quick surface sealing. Polymer-enhanced hardeners offer both film-forming and densifying for mechanical protection. This densifier technology makes your concrete incredibly resilient. These densifiers are essential for long-term concrete protection. You will find many types of hardeners, each a powerful densifier.

Typical Applications

You can use these hardeners on many types of concrete floors. They are perfect for industrial settings where heavy machinery operates. Commercial spaces, like warehouses and retail stores, also benefit greatly. Even residential garages can become much tougher. These hardeners transform basic concrete into tough, long-lasting surfaces. They handle heavy machinery and continuous movement well. The ease of application makes them a popular choice. You can also use them as a base for polished concrete floors, creating a highly durable and attractive finish. This application makes your concrete floor ready for anything. A good concrete densifier ensures longevity. This hardener type is versatile.

Benefits of Water-Based Crystal Floor Hardeners

You will find many advantages when you choose a water-based crystal floor hardener for your concrete. These products do more than just sit on the surface; they transform your floor from within.

Enhanced Durability and Abrasion Resistance

These hardeners significantly strengthen your concrete surface. They reduce wear and tear from daily use, heavy foot traffic, and even machinery. You can expect your floor to gain up to 50% extra strength and life. This means your concrete will stand up to challenges much better. You get excellent resistance to wear that keeps your floor looking good for years.

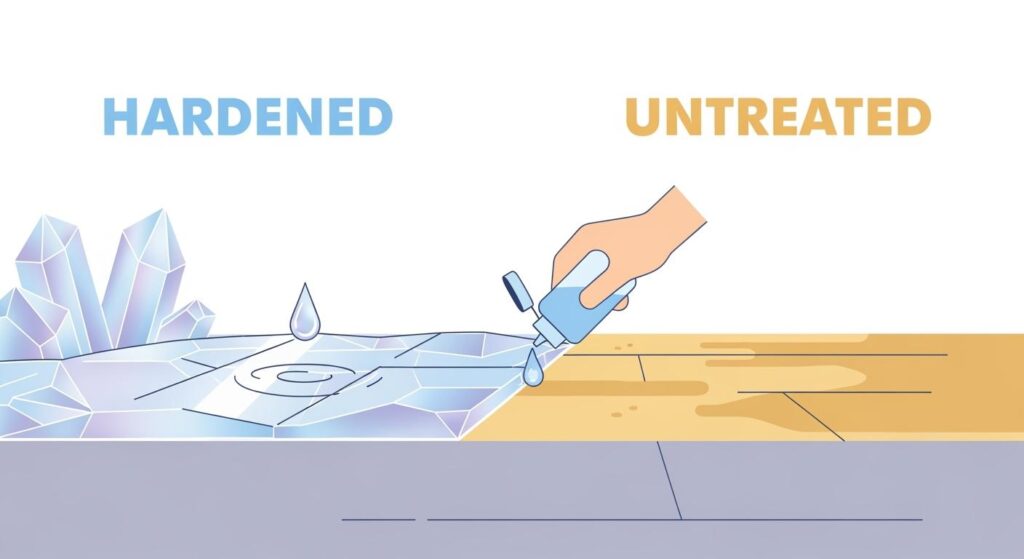

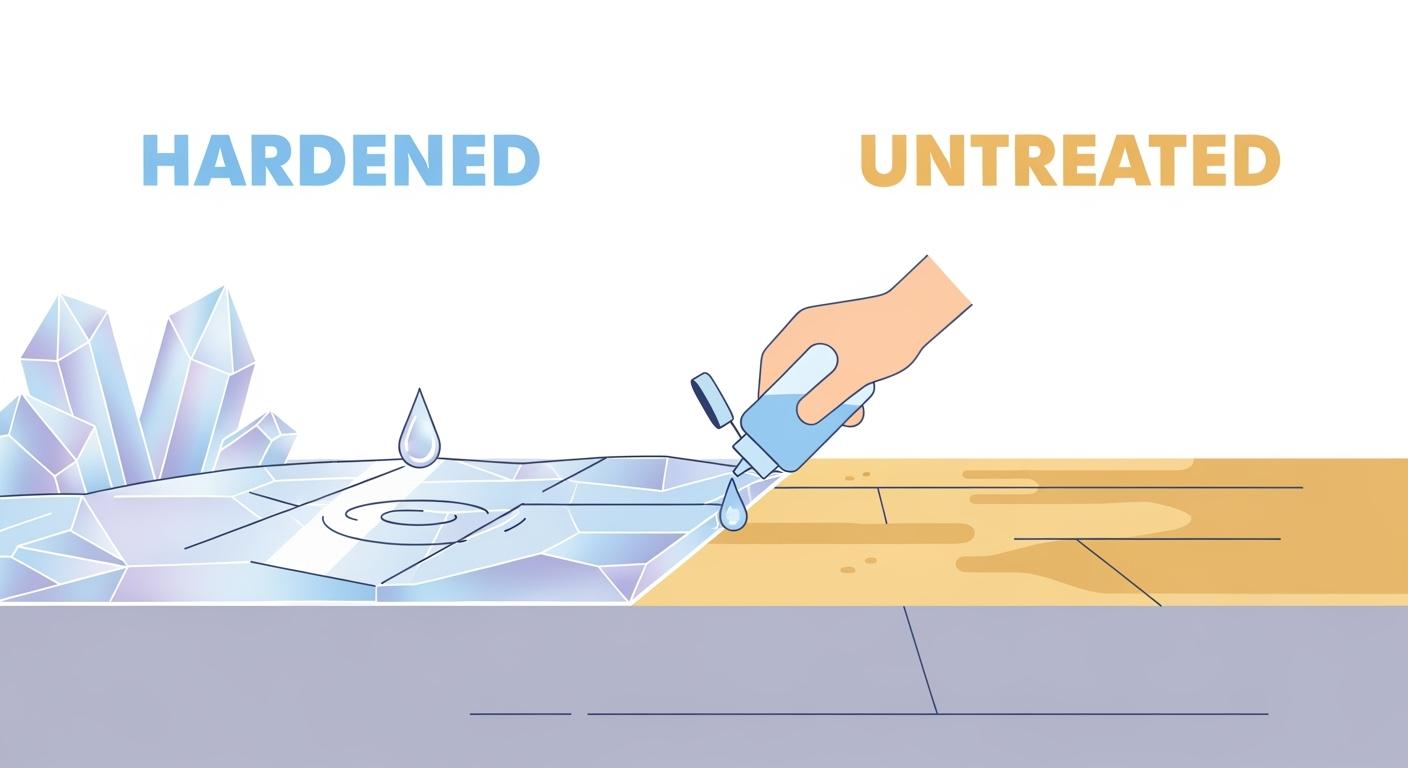

Effective Dust Proofing

One of the most annoying issues with untreated concrete is dusting. This happens when tiny particles break off the surface. Water-based hardeners eliminate this problem. They penetrate the concrete and bind these loose particles. This creates a dust-free environment. You will notice a cleaner space, which is great for both health and maintenance.

Increased Hardness and Density

These hardeners make your floors much more resistant to impact and heavy traffic. How do they do this? A concrete densifier works by seeping into the microscopic pores and capillaries of the concrete. Inside, the densifier reacts with calcium hydroxide, also known as free lime. This reaction creates insoluble calcium silicate hydrate (CSH) crystals. CSH is the same mineral compound that gives concrete its strength. These new CSH crystals fill the tiny voids within the concrete, making it much denser and less porous. This process permanently increases the hardness and density of your floor.

Improved Chemical Resistance

Spills and stains can ruin an untreated concrete floor. These hardeners offer significant protection. They create a barrier that resists many common chemicals. For example, specific magnesium fluorosilicate hardeners can protect against various sulfates like aluminum sulfate and magnesium sulfate. They also resist chlorides such as ammonium chloride and ferric chloride. You get protection from acids like lactic acid and phosphoric acid, and even many oils like olive oil and machine oils. Other substances like glucose, glycerine, and even seawater also face increased resistance. Another type of densifier, like sodium silicate with siliconate, broadly protects against water, moisture, efflorescence, dirt buildup, mold, mildew, salts, and deicing chemicals.

Eco-Friendly and Low VOC

You can feel good about using these hardeners because they are environmentally friendly. They have low Volatile Organic Compound (VOC) levels. This means fewer harmful chemicals are released into the air. These products comply with federal AIM rule VOC regulations and VOC standards in many states. They dry fast, have little to no odor, and leave a crystal-clear finish. This makes them a healthier choice for both you and the environment.

Easier Maintenance

Maintaining a treated concrete floor becomes much simpler. You will find cleaning easier, and you won’t need to wax the floor. These hardeners make your floor generally maintenance-free. This saves you time and effort in the long run.

Cost-Effectiveness

While there’s an initial investment, these hardeners offer long-term savings. Their durability means your floor lasts longer, reducing the need for frequent repairs or replacements. The low maintenance requirements also cut down on cleaning costs and labor. You get a great return on your investment.

Self-Sealing Hairline Cracks

Some densifier products can even self-seal hairline cracks up to 0.5 mm. This is a fantastic benefit. The hardener penetrates these tiny cracks, creating a watertight barrier. This not only strengthens the concrete but also protects it against water damage. Your floor becomes more robust and resilient.

Limitations of Crystal Floor Hardeners

While water-based crystal floor hardeners offer many benefits, they also come with certain limitations. You need to understand these drawbacks before you decide if they are the right choice for your project. Knowing the full picture helps you make the best decision for your floor.

No Aesthetic Change

You might hope for a dramatic visual transformation, but these hardeners do not inherently change the look of your concrete. Products like lithium silicate densifiers are clear. They have little to no noticeable effect on the appearance of your concrete surfaces once dry. If you want a polished look, you can achieve it. This requires proper application and buffing on burnished or polished surfaces. Otherwise, your concrete will look much the same, just stronger.

Crucial Surface Preparation

Applying crystal floor hardeners is not a simple pour-and-go process. You must prepare the surface meticulously. This step is absolutely crucial for the hardeners to work effectively. If you skip or rush this, the hardeners might not penetrate or bond correctly. Here are the essential steps you need to take:

Saturate and Dampen: First, saturate the surface with water for several hours. Keep it damp, but remove any standing water before you apply the hardener.

Inspect and Repair: Look for defects like honeycombs, voids, and cracks. You must repair these with suitable cementitious repair mortar.

Clean Thoroughly: Remove all dirt, oil, grease, laitance, and other contaminants. You can use wire brushing, water jetting, or sandblasting.

Stop Leaks: If you have active water leaks, stop them with a plugging compound. Repair any damaged or unsatisfactory substrates with patching compound.

Address Larger Cracks: For holes and cracks 1/16 inch (1.6 mm) wide or larger, remove loose chips. Cut a reveal at least 1 inch (25 mm) deep with perpendicular sides. Then, fill these with patching compound flush with the surface.

Remove Residue: Get rid of efflorescence, chalk, dust, dirt, mortar spatter, grease, oils, paint, curing compounds, and form-release agents. This ensures proper bonding.

Profile the Surface: Create a concrete surface profile according to the manufacturer’s instructions.

Clean to Standards: Clean concrete surfaces following ASTM D4258, D4259, D4260, and D4261. This might involve etching with muriatic acid, mechanical abrading, abrasive-blast cleaning, or sandblasting/bushhammering.

Decontaminate: Remove all materials that could affect adhesion. This includes dirt, oil, grease, chemicals, and curing compounds. Use methods like detergent scrubbing, low-pressure water cleaning, or steam cleaning.

Test pH: After decontamination, test the pH of the concrete surface. It should be between 11 and 13. If it is 10 or lower, you need more decontamination. You might even need to remove and replace the contaminated concrete.

Remove Weak Spots: Get rid of weak or damaged concrete. Detail surface defects like blowholes and voids. Use appropriate repair materials to fill these imperfections and level the surface.

Grind High Spots: Mechanically remove any high spots, for example, by grinding.

Prepare Substrates: Mechanically prepare concrete substrates to remove cement laitance, existing coatings, and curing compounds. This creates a clean, dry, and contaminant-free profile using techniques like shotblasting or grinding.

Not a Repair Solution

You should know that crystal floor hardeners are not a magic fix for damaged concrete. They will not repair existing cracks, spalling, or other structural issues. Think of them as a preventative measure and a strengthener for sound concrete. You must address any existing damage before you apply these hardeners.

Limited Water Repellency

While these hardeners densify your concrete and make it less porous, they do not make it completely waterproof. They offer improved resistance to spills and moisture penetration. However, they are not a substitute for a dedicated waterproofing membrane. If you need full waterproofing, you will need additional treatments.

Application Sensitivity

Applying these hardeners requires care and precision. You need to follow the manufacturer’s instructions exactly. Incorrect application can lead to uneven results, white hazing, or other surface imperfections. For example, applying too much or letting it dry too quickly can cause problems. The success of the application heavily depends on proper technique.

Required Curing Time

You cannot immediately subject your treated floor to heavy use. Water-based crystal floor hardeners need time to cure. For products like ‘Concrete Binder & Hardner’, you should wait 24 hours before allowing heavy traffic. This assumes ideal conditions, around 60-70°F temperature and good ventilation. If temperatures are lower, the curing period will extend. You must respect this curing time to ensure the hardeners fully integrate and provide maximum benefits.

Concrete Suitability Varies

Not all concrete is created equal, and not all concrete reacts the same way to these hardeners. Older concrete, very porous concrete, or concrete with high amounts of fly ash might not achieve the same level of densification as newer, denser slabs. You should always test a small, inconspicuous area first. This helps you see how your specific concrete will react to the hardeners.

When to Choose Water-Based Hardeners

You might wonder if water-based crystal floor hardeners are the right fit for your project. Consider your goals and the current state of your floor. These products offer specific advantages that make them ideal for certain situations.

Ideal Use Cases

You should choose these hardeners when you need to strengthen weak, dusty, or poor-quality concrete. They penetrate deep into the material, making it much more robust. For example, a water-based crystal floor hardener like Concrete Binder & Hardener is perfect for projects aiming for a dust-free, hardened surface. You can transform an old, worn-out floor into a durable, long-lasting one.

Project Goal Considerations

When you plan your project, think about what you want to achieve. These hardeners significantly improve concrete properties. You will see enhanced intensity, hardness, and resistance to permeability and abrasion. They effectively solve common concrete problems like loose structure, dust, cracking, and short service life. You can expect a 30% increase in substrate intensity and a Mohs Hardness of 7 or more. Your floor’s abrasive resistance will improve by 5 to 8 times. This greatly increases concrete density, leading to better sealing and anti-pollution performance. You get a smooth, burnished, anti-slippery, and long-lasting surface. Plus, these hardeners are water-based and environmentally friendly, suitable even for food-grade production, and offer a high fireproofing grade. They are also excellent for renovating old, damaged floor hardener systems.

You now understand that water-based crystal floor hardeners significantly boost concrete durability, reduce dusting, and even self-seal minor cracks, offering an eco-friendly solution. Remember, these hardeners don’t change aesthetics, and proper surface preparation is vital. While not a universal fix, they are excellent for projects prioritizing durability, dust control, and low maintenance. Weigh these points for your best flooring decision.

FAQ

What is the main benefit of using these hardeners?

You get significantly stronger concrete. It resists wear and tear better. You also eliminate concrete dust.

Do these hardeners change my floor’s look?

No, they are clear. They do not change your concrete’s appearance. You need polishing for a shiny look.

Can I use them to fix cracks?

No, they are not a repair solution. You must fix existing damage first. They strengthen sound concrete.

See Also

Floor Hardening: Benefits and Drawbacks for Various Surface Types

Understanding Liquid Concrete Hardeners, Sealers, and Densifiers Explained

Concrete Floor Hardeners: Their Purpose and Operational Mechanisms Unveiled

Selecting the Optimal Floor Hardener: A 2025 Comparative Guide

Buying Guide: Concrete Densifiers, Hardeners, and Sealers Explored