Concrete fortifiers are clever additives. They boost concrete’s strength, durability, and other vital properties. This makes them very important in construction. This post delves into various types of Concrete Fortifier, comparing their uses. It helps you pick the best one for your building projects.

Key Takeaways

Concrete fortifiers make concrete stronger and last longer. They also help it resist cracks and chemicals.

There are three main types of fortifiers: chemicals, minerals, and fibres. Each type helps concrete in different ways.

Choose the right fortifier for your project. This makes sure your building is strong and lasts a long time.

Main Concrete Fortifier Categories

Concrete fortifiers fall into three main groups: chemical admixtures, mineral admixtures, and fibrous reinforcements. Each type offers unique benefits, helping engineers tailor concrete properties for specific project needs.

Chemical Admixtures for Concrete

Chemical admixtures are liquids or powders added to concrete mixes just before or during mixing. They significantly alter concrete’s properties. Plasticisers, also known as superplasticisers, improve workability without adding more water. They achieve this by dispersing cement particles, creating repulsive forces that free up trapped water. This also forms a lubricating film between particles, reducing friction. Air-entraining agents introduce tiny, stable air bubbles into the mix, greatly improving concrete’s resistance to freeze-thaw cycles. Typical dosage rates for these agents, like Sika® AIR, range from 50-150 ml per cubic metre for general use, though low slump concrete might need more. Retarders slow down the setting time, which is useful for large pours or hot weather. They delay the cement hydration process, extending the concrete’s plastic state. Accelerators, conversely, speed up early strength development. For example, some accelerators can achieve up to 1,000 psi per hour during the second stage of hardening, offering 50% increased overnight strength gains. Acrylic fortifiers enhance bonding, surface densification, and chemical resistance, while bonding agents help new concrete adhere to existing surfaces.

Mineral Admixtures for Concrete

Mineral admixtures are finely divided materials added to concrete. Fly ash, a by-product of coal combustion, improves strength, workability, and reduces the heat of hydration. HVFA-80 concrete, for instance, showed a compressive strength of 22 MPa at 7 days, increasing to 71 MPa at 450 days, demonstrating superior long-term durability. Silica fume, a by-product of silicon and ferrosilicon alloy production, creates very high-strength concrete with excellent abrasion resistance. Ground granulated blast-furnace slag (GGBS), a by-product from iron manufacturing, enhances durability, reduces permeability, and offers significant environmental benefits. Using GGBS can reduce carbon emissions and improve resistance to chemical attacks. Other fillers also contribute to density and compactness.

Fibrous Reinforcements in Concrete

Fibrous reinforcements involve adding various types of fibres to the concrete mix. Steel fibres boost tensile strength and control cracking. These fibres typically have aspect ratios (length to diameter) from 40 to 60, with 38 mm being a common length. Synthetic fibres, often made from polypropylene or polyethylene, are excellent for controlling plastic shrinkage cracks and improving impact resistance. Micro synthetic fibres are particularly effective in mitigating early-age plastic shrinkage. Natural fibres, such as sisal or jute, offer a sustainable option, primarily combating plastic and drying shrinkage. They improve compressive, tensile, and flexural strengths, and enhance durability against water absorption and chemical attack. While natural fibres have limited structural use in some applications, they are a viable, low-cost choice, especially in developing countries.

Comparing Concrete Fortifier Benefits and Applications

This section offers a direct comparison of different fortifiers. It looks at how they perform against specific criteria.

Strength and Durability Enhancement

Different fortifiers significantly boost concrete’s strength and durability. Silica fume and steel fibres, for example, greatly improve compressive strength. Researchers developed a high-strength all-lightweight self-compacting concrete (HALSCC). This concrete had a compressive strength over 40 MPa. It included silica fume and hybrid steel fibres. The study showed that hybrid length steel fibres specifically improved the mechanical properties of the concrete. This was better than using just one type of fibre. For instance, a concrete mix with 20% PCA, 20% silica fume, and 0.75% steel fibre achieved a compressive strength of 17.9 MPa. This makes it suitable for high-performance concrete or industrial flooring.

Concrete Mix Components | Compressive Strength (MPa) |

|---|---|

RPAC with 20% PCA, 20% silica fume, and 0.75% steel fiber | 17.9 |

Acrylic fortifiers also play a vital role in enhancing strength. Xycrylic Admix modified mortars show much better flexural strength compared to unmodified mortars. These modified mortars also have superior adhesive and impact strengths. They offer excellent abrasion resistance too. This makes them ideal for thin sections, areas needing resistance to excessive vibration, and heavy traffic applications.

Workability and Placement Considerations

Workability is how easily concrete flows, pumps, and finishes. Plasticisers are excellent for improving workability. They allow concrete to flow smoothly without adding extra water. This is crucial for complex pours. Air-entraining agents introduce tiny air bubbles. These bubbles improve pumpability and make concrete easier to handle, especially in cold weather. Certain mineral admixtures, like fly ash, also enhance workability. They make the mix more cohesive and less prone to segregation.

Crack Control and Impact Resistance

Controlling cracks is essential for concrete’s longevity. Various fibres and some mineral admixtures effectively reduce cracking. Micro synthetic fibres provide good resistance to plastic shrinkage. Fibre reinforcement generally leads to less drying shrinkage and plastic shrinkage.

Adding basalt fibres (BFs) to self-compacting geopolymer concrete (SCGC) reduces drying shrinkage rates. This is compared to plain SCGC.

SCGC reinforced with a 2% dosage of hybrid-length BFs recorded the lowest drying shrinkage rate.

No plastic shrinkage cracks appeared in mixes reinforced with 12 mm (1.5% and 2% dosages), 30 mm, and hybrid-length BFs.

Fibres made of steel, glass, or organic polymers (plastics) are common. Sometimes natural fibres like sisal and jute are used. They all combat plastic and drying shrinkage. Fibre reinforcement helps prevent cracking and damage. This extends the lifespan of concrete. Fibres also stop existing cracks from getting wider. This is very important for pavements or blast-resistant structures.

Permeability and Chemical Resistance

Reducing permeability and enhancing chemical resistance are critical for harsh environments. GGBS, silica fume, and acrylic fortifiers are excellent for this. GGBS and silica fume create a denser concrete matrix. This reduces the pathways for water and chemicals to penetrate. This makes the concrete more resistant to chemical attack. It is crucial for marine environments or wastewater treatment plants. Acrylic fortifiers also improve chemical resistance. They form a protective layer within the concrete, making it less susceptible to corrosive substances.

Cost-Effectiveness and Environmental Impact

The economic and environmental aspects of fortifiers vary. Material cost, application cost, and embodied carbon all play a part. Some fortifiers, like certain chemical admixtures, can be quite expensive per litre. For example, a 5L container of CHEMFORCE Fortifier Plus Consolidator and H20 Repellant costs $197.00. SuprSheen Fortifier Plus, also 5L, costs $276.00 + GST. However, their long-term benefits often outweigh the initial cost. They extend the concrete’s lifespan and reduce maintenance.

Product Name | Volume | Price (AUD) |

|---|---|---|

CHEMFORCE Fortifier Plus Consolidator and H20 Repellant | 5L | $197.00 |

Product Name | Volume | Price (AUD) |

|---|---|---|

SuprSheen Fortifier Plus | 5L | $276.00 + GST |

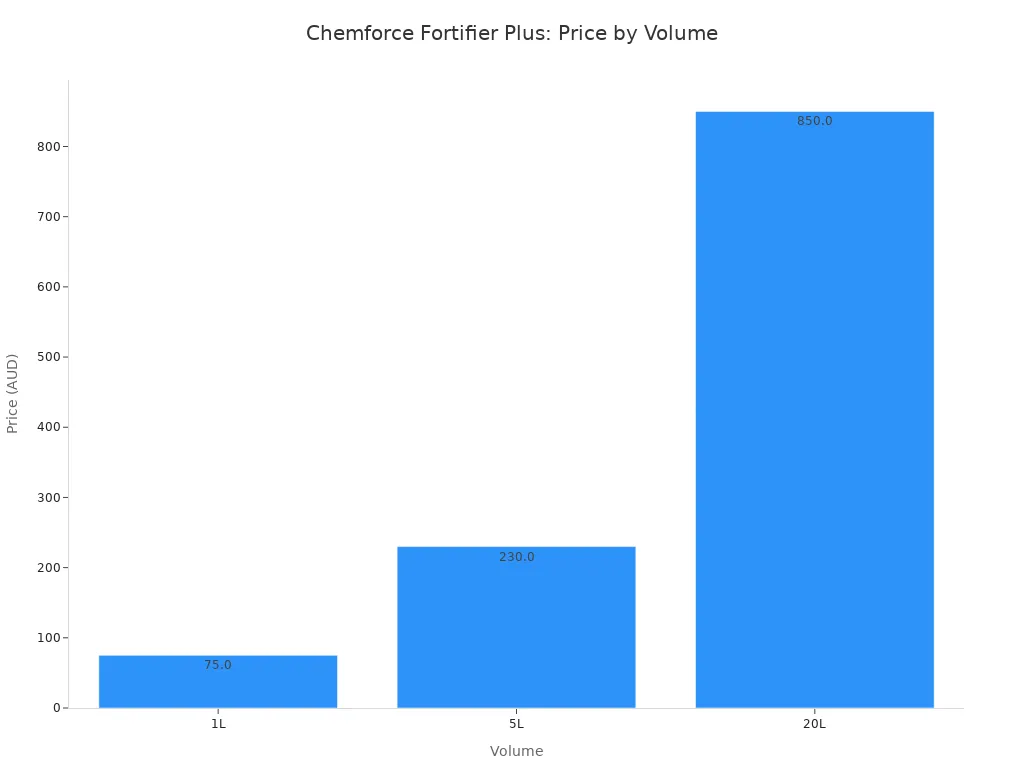

Larger volumes often offer better value.

Product Name | Volume | Price (AUD) |

|---|---|---|

Chemforce Fortifier Plus | 1L | $75.00 Inc GST |

Chemforce Fortifier Plus | 5L | $230.00 Inc GST |

Chemforce Fortifier Plus | 20L | $850.00 Inc GST |

Mineral admixtures like fly ash and GGBS are often by-products of other industries. This makes them more sustainable. They reduce the amount of cement needed, lowering embodied carbon. This makes them an environmentally friendly Concrete Fortifier choice. While fibres add to material costs, they can reduce the need for traditional reinforcement. This simplifies construction and saves labour costs.

Selecting the Right Concrete Fortifier

Factors Influencing Selection

Choosing the correct Concrete Fortifier involves careful thought. Engineers consider several key factors. First, they look at the project’s specific requirements. Does the concrete need exceptional strength, improved durability, or better crack control? The environment also plays a big part. For instance, a structure in a marine setting needs different fortifiers than one in a cold climate. Budget constraints always influence decisions. People also think about sustainability goals. They might choose fortifiers that reduce the carbon footprint. Finally, the specific application, such as industrial flooring or a residential foundation, guides the selection process.

Fortifier Combinations and Case Studies

Often, using just one fortifier does not meet all project demands. People frequently combine different types. This approach creates concrete with enhanced properties. For example, a project might use a superplasticiser to improve workability for a complex pour. They could also add silica fume for high strength and abrasion resistance. This combination achieves synergistic effects, meaning the combined result is greater than the sum of its parts. Many successful construction projects demonstrate the benefits of these combined fortifiers. They show how tailored fortifier blends lead to superior concrete performance and long-term structural integrity.

Concrete fortifiers play diverse roles, significantly enhancing concrete properties. Selecting the right Concrete Fortifier type, based on project needs, is crucial. Informed choices optimise performance, ensuring long-term structural integrity and sustainability for your builds.

FAQ

What do concrete fortifiers actually do?

Concrete fortifiers improve concrete’s properties. They make it stronger, more durable, and easier to work with. They also help resist cracks and chemicals.

Can you combine different types of fortifiers?

Yes, you often combine different fortifiers. This creates concrete with enhanced properties. The combined effect is usually better than using just one type.

Are fortifiers always needed in concrete projects?

Not always, but they are very important. Fortifiers help concrete meet specific project demands. They ensure long-term performance and structural integrity.

See Also

Unveiling the True Distinction: Concrete Densifiers Versus Hardeners Explained

Hydraulic Versus Standard Concrete: Understanding Their Core Distinctions

Concrete Densifiers: Their Purpose and Operational Mechanisms Uncovered

Selecting Optimal Floor Hardeners: A Comprehensive 2025 Comparative Handbook

Demystifying Concrete Floor Hardeners: Their Essence and Operational Principles